To create an epoxy resin table, you need to prepare the wood thoroughly. Make sure you remove the bark, as this will not provide an optimal bonding surface for the resin. The wood should be smooth, and the epoxy should adhere to it well. Start sanding the wood with a coarse sandpaper, and progress to a finer one. When finished, sand the table with a fine sandpaper and finish with a sanding machine.

Choosing the right type of resin is important. There are several types of resin that you can choose from. First, you have to select the type of table that you want to build. An epoxy resin table is different from a traditional wood table because it is made of high quality materials. Most manufacturers use polyester and acrylic resins, but you can also look for natural products. Second, epoxy resin tables don't get damaged by moisture. It is also more durable than a traditional wood table.

When casting the epoxy resin, the process is quite simple. To make a table with a high-quality resin, you need a mold that has the proper shape. In order to make a proper mold, use MDF boards that are at least 15mm thick. Then, add two side panels to the table top. These sides should be ten millimeters higher than the top of the table, which can be secured to the underside using screws or hot glue. Once the sides are glued on the tabletop, apply clear sanitary silicone to the edges.

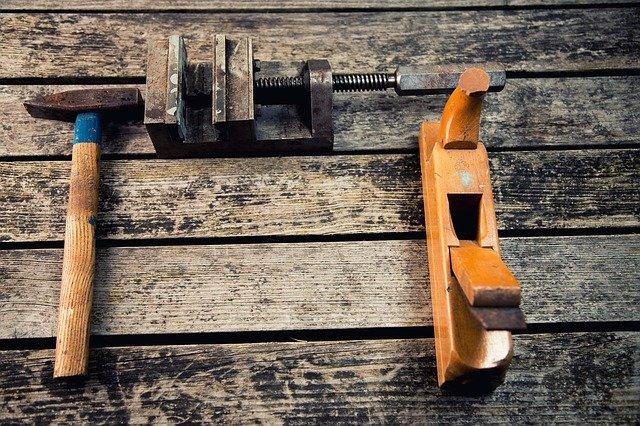

After making the mold, the next step is to pour the epoxy resin into the desired thickness. This process takes about 72 hours, so you should wait two weeks before removing the table from the mold. In some cases, you may need to cast the resin in several layers. In this case, the thickness of the tabletop will decide the maximum layer height. You can also apply a finish to the surface of the table using a dead blow mallet or a wooden wedge.

To create an epoxy resin table, you need a stable working environment. It should be dry, dust-free and heated (if it is winter). It should also be well ventilated. In addition, the temperature should be about twenty degrees Celsius or higher. In these conditions, the resin can react differently with heat and can crack and peel. For these reasons, it is essential to keep the workshop warm and dry before attempting to create an epoxy resin table.

To create an epoxy resin table, you need to prepare the wood in the correct way. To begin, you need to prepare the mold by measuring the width and length of the tabletop and cutting it to fit. Once you've cut the wood, you can start pouring the resin. If you're using a track saw, make sure you use a 15mm board for the side panels. You should also take care of the bark on the wood as it will affect the final appearance of your table.