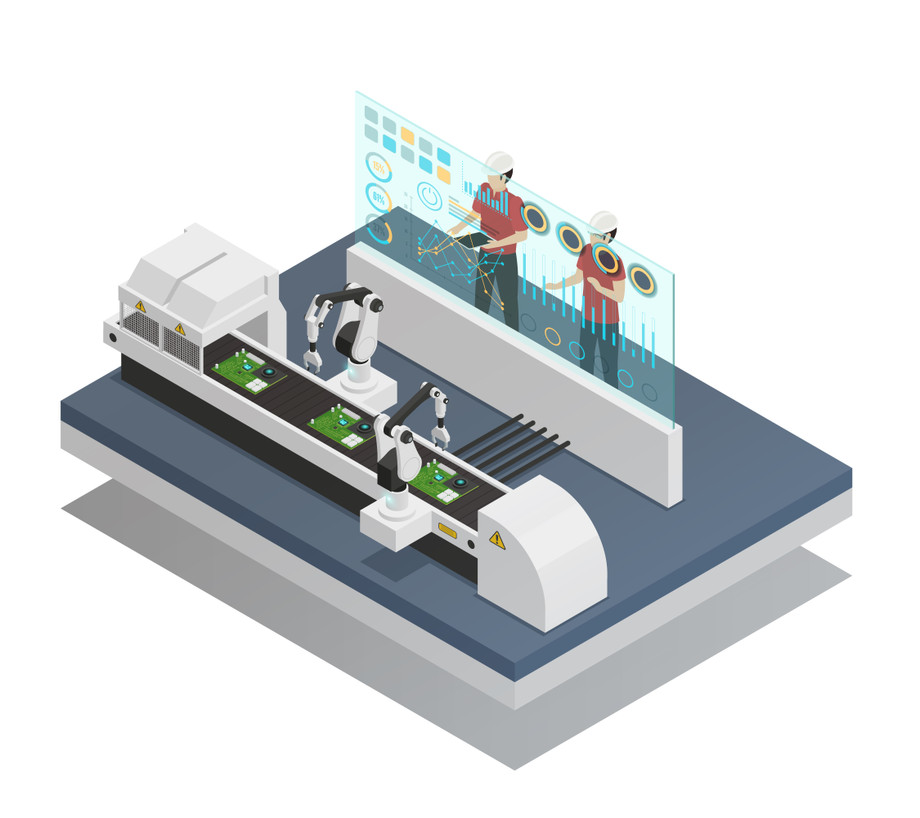

As the global race toward sustainability accelerates, smart manufacturing has become a powerful catalyst in the transition to net-zero emissions. Today’s advanced manufacturing ecosystems—powered by IoT, AI, machine learning, and digital twins—are redefining efficiency, productivity, and environmental responsibility.

By enabling real-time visibility, predictive insights, and data-driven decision-making, smart manufacturing technologies are not just transforming production—they are fueling a strategic shift toward a cleaner, greener industrial future.

“Digital technologies in manufacturing can reduce emissions by up to 20% by 2030, with digital twins playing a central role.” – World Economic Forum

What Is Web Synergies’ Integrated Suite for Smart Manufacturing?

The Web Synergies Integrated Suite is a future-ready platform designed to help manufacturers optimize operations while accelerating sustainability goals.

It delivers real-time monitoring, predictive maintenance, AI-driven insights, and seamless IT/OT integration—dramatically reducing energy consumption, downtime, and operational waste.

Whether you are modernizing legacy plants or building smart factories, the Suite ensures flexibility, scalability, and environmental resilience.

How Smart Manufacturing Drives the Net-Zero Revolution

1. Real-Time Monitoring and Control

IoT-enabled sensors provide live insights into machine health, energy usage, and emission levels. Manufacturers can instantly optimize processes and reduce carbon output.

McKinsey reports that real-time monitoring can boost energy efficiency by up to 15%.

2. Digital Twin Technology

Digital twins create virtual replicas of production assets for simulation, stress testing, and lifecycle optimization. They enhance accuracy, reduce breakdowns, and enable predictive maintenance—cutting unnecessary emissions.

Deloitte projects that digital twins will be used in 89% of advanced manufacturing operations by 2028.

3. IT/OT Convergence

Unifying Information Technology and Operational Technology eliminates silos, ensuring seamless data flow and enabling smarter energy management, transparency, and sustainability compliance.

4. Adoption of Bio-Based Materials

Smart manufacturing ensures traceability and quality control for renewable, bio-based raw materials—reducing reliance on petroleum-based inputs and lowering lifecycle emissions.

5. Waste Reduction and Recycling

AI-driven analytics identify inefficiencies, support circular workflows, and enable scrap repurposing and real-time inventory optimization—turning waste into usable value.

6. Development of Sustainable Products

Smart tools enable energy-conscious design for low-impact products such as lightweight vehicles, efficient appliances, and eco-friendly industrial components.

7. Circular Economy Models

From raw material tracking to end-of-life management, smart manufacturing supports closed-loop systems through reuse, remanufacturing, and recycling strategies.

8. Predictive Maintenance

AI-powered models detect issues before failures occur—reducing downtime, eliminating unnecessary machine cycles, and lowering carbon emissions.

9. Energy Management

AI and digital twins work together to optimize energy usage across facilities. Smart plants can also integrate renewable energy sources to enhance resilience and reduce emissions.

A Capgemini study found that 40% of manufacturers using AI for energy management achieved measurable reductions in energy costs and CO₂ emissions.

10. AI and Machine Learning

Machine learning continuously refines operations—from quality control to workflow scheduling—creating agile, low-impact factories capable of maintaining sustainability at scale.

Why Partner with Web Synergies?

Partnering with Web Synergies means collaborating with a team at the forefront of sustainable industrial transformation.

Our Integrated Suite connects technology with purpose—turning data into action, insights into innovation, and sustainability into measurable impact.

From leaner workflows and lower emissions to circular production and efficient energy usage, Web Synergies helps future-proof your manufacturing operations. As BCG stated in 2023, sustainability is no longer an add-on—it is a competitive differentiator.

Let’s work together to turn your net-zero ambition into operational reality—one smart step at a time.

FAQs

1. What is smart manufacturing?

Smart manufacturing uses IoT, AI, and digital twins to automate, monitor, and optimize production in real time—creating intelligent, adaptive, and connected factories.

2. Why is smart manufacturing essential for net-zero goals?

It provides precise control over energy usage, materials, and emissions, making it critical for aligning industrial operations with global climate targets.

3. How does smart manufacturing optimize energy in real time?

Sensors and AI analytics track consumption patterns, detect inefficiencies, and automatically recommend corrective actions—ensuring no watt is wasted.

4. How does predictive maintenance improve sustainability?

It prevents equipment failures, reduces unnecessary energy consumption, and extends asset lifespan—lowering both operational and environmental costs.

5. How do digital twins and IT/OT convergence reduce emissions?

Digital twins simulate efficient designs, while IT/OT convergence ensures these improvements are executed seamlessly across production environments.