Fuel-Saving Hacks Every Construction Fleet Manager Should Know

What You Need to Know About Construction Fleet Fuel Monitoring Systems

Construction fleet fuel monitoring systems can revolutionize your operations. They use sensors and software to track fuel levels, consumption, and refueling events in real-time. You'll benefit from improved efficiency, cost savings through theft prevention, and a reduced environmental impact. Look for features like real-time tracking, theft prevention measures, and integration with existing telematics. Implement the system carefully, with proper training and a phased rollout approach. You'll need to overcome challenges like ensuring data accuracy and user-friendly interfaces. As technology advances, expect to see more sophisticated analytics and predictive maintenance capabilities. construction fleet anti-theft measures. Exploring these systems further could unveil significant advantages for your fleet

Key Takeaways

- Fuel monitoring systems use sensors, data transmitters, and software to track fuel levels and consumption in real-time.

- These systems improve operational efficiency, reduce costs, and minimize environmental impact for construction fleets.

- Key features include real-time tracking, theft prevention measures, and integration with existing telematics infrastructure.

- Effective implementation requires seamless software integration, comprehensive personnel training, and a phased rollout approach.

- Future trends in fuel monitoring include advanced analytics, predictive maintenance integration, and real-time optimization algorithms.

Understanding Fuel Monitoring Systems

Three key components make up a fuel monitoring system: sensors, data transmitters, and analysis software. Sensors installed in fuel tanks accurately measure fuel levels, consumption rates, and refueling events. Data transmitters securely relay this information to a central database, often in real-time. Analysis software processes the collected data, generating reports and observations for fleet managers.

To guarantee ideal performance, prioritize data accuracy. construction fleet anti-theft measures when selecting a fuel monitoring system. Precise measurements are vital for identifying inefficiencies, detecting theft, and making informed decisions. Consider system compatibility with your existing fleet management tools to streamline operations and avoid data silos

Modern fuel monitoring systems offer additional features like GPS tracking, engine diagnostics, and driver behavior analysis. These integrated solutions provide a thorough view of your fleet's performance and safety metrics. When implementing a fuel monitoring system, train your staff on proper use and data interpretation to maximize its benefits.

Regular maintenance and calibration of sensors are essential for consistent data quality. Establish protocols for addressing discrepancies and troubleshooting system issues promptly. By leveraging accurate fuel data, you'll enhance fuel consumption, reduce costs, and improve overall fleet efficiency.

Benefits for Construction Fleets

Construction fleets stand to gain significant advantages from implementing fuel monitoring systems. These systems provide real-time data (construction fleet anti-theft measures) on fuel consumption, allowing you to identify inefficiencies and optimize fuel usage across your fleet. By tracking fuel levels and consumption rates, you'll reduce the risk of unexpected fuel shortages, minimizing downtime and improving project timelines

Cost savings are a primary benefit of fuel monitoring systems. You'll be able to detect fuel theft, unauthorized usage, and excessive idling, leading to reduced fuel expenses. Additionally, these systems help you plan more efficient routes, further cutting fuel costs and vehicle wear.

Environmental impact is another vital factor. By optimizing fuel consumption, you'll reduce your fleet's carbon footprint, aligning with sustainability goals and potentially qualifying for green certifications (construction fleet anti-theft measures) - enhance construction fleet tracking to reduce fuel costs. This can enhance your company's reputation and open doors to environmentally conscious clients

Fuel monitoring systems also improve safety by ensuring vehicles are properly maintained and fueled. You'll receive alerts for maintenance needs, reducing the risk of breakdowns and accidents. Furthermore, these systems can track driver behavior, encouraging safer driving practices and reducing the likelihood of fuel-related incidents on construction sites.

Key Features to Look For

When selecting a fuel monitoring system for your construction fleet, prioritize key features that maximize efficiency and control. Look for systems offering real-time data tracking, allowing you to instantly access fuel consumption metrics and make data-driven decisions. Guarantee the system includes strong fuel theft prevention measures and seamlessly integrates with your existing telematics infrastructure for thorough fleet management.

Real-Time Data Tracking

advanced fuel management systems for fleets

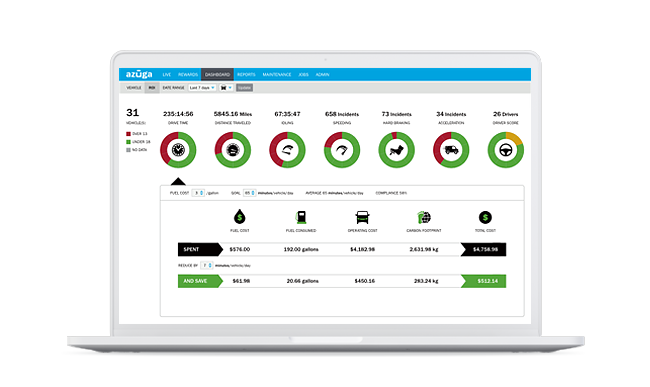

advanced fuel management systems for fleetsTo maximize the efficiency of your construction fleet's fuel monitoring system, real-time data tracking is vital. This feature allows you to monitor fuel consumption, vehicle locations, and driver behavior as it happens, enabling quick decision-making and immediate problem-solving.

Look for a system with high data accuracy to guarantee you're basing decisions on reliable information. The user interface should be intuitive and easy to maneuver, allowing you to quickly access and interpret the data you need (click here). Opt for a system that provides customizable dashboards and alerts, so you can focus on the metrics most relevant to your operations

Real-time tracking helps identify fuel theft, excessive idling, and inefficient routing immediately. This rapid response capability can notably reduce fuel waste and improve overall fleet efficiency. Additionally, it enhances safety by allowing you to monitor driver behavior and vehicle performance in real-time, potentially preventing accidents and breakdowns.

Choose a system that offers mobile accessibility. click here, enabling you to monitor your fleet from anywhere (construction fleet anti-theft measures). This feature is vital for maintaining oversight and responding to issues promptly, even when you're away from the office

Fuel Theft Prevention

Preventing fuel theft is a critical aspect of any strong fleet fuel monitoring system. To safeguard your construction fleet's fuel resources, you'll need to implement solid fuel theft detection and preventative measures. Look for systems that offer real-time alerts for suspicious activities, such as after-hours fueling or sudden drops in tank levels. These features can help you quickly identify and respond to potential theft incidents.

When selecting a fuel monitoring system, prioritize the following key features: construction fleet anti-theft measures.

- Tank level sensors with high accuracy and tamper-proof design

- Fuel flow meters to measure and record all fuel dispensing activities

- Automated reconciliation of fuel purchases, usage, and inventory

- Integration with vehicle telematics for cross-referencing fuel consumption data

Advanced systems may also include video surveillance capabilities at fueling stations, adding an extra layer of security. By implementing these preventative measures, you'll not only deter theft but also create a safer work environment for your team. Remember, a thorough fuel monitoring system isn't just about tracking usage—it's about protecting your essential resources and maintaining operational efficiency (construction fleet cost-saving strategies). With the right tools in place, you can greatly reduce the risk of fuel theft and its associated costs

Integration With Telematics

comprehensive tracking for construction fleet management

comprehensive tracking for construction fleet managementIntegration with telematics is an important feature for modern construction fleet fuel monitoring systems. When selecting a system, you'll want to guarantee it seamlessly integrates with your existing telematics infrastructure. This integration allows for an all-encompassing view of your fleet's performance, combining fuel data with other vital metrics.

Look for systems that offer real-time data transmission and advanced analytics capabilities. These telematics advancements enable you to track fuel consumption patterns, identify inefficiencies, and make data-driven decisions to optimize your fleet's operations (construction fleet anti-theft measures). The system should provide customizable reports and dashboards, allowing you to visualize fuel usage trends alongside vehicle location, engine hours, and driver behavior

Prioritize solutions that offer API connectivity, guaranteeing compatibility with your current software ecosystem. This interoperability streamlines data flow and enhances overall fleet management efficiency. Additionally, seek systems that incorporate predictive maintenance features, using fuel consumption data to forecast potential issues and prevent costly breakdowns.

Implementation and Integration Strategies

To maximize the benefits of your fuel monitoring system, you'll need to focus on three key implementation strategies. First, guarantee seamless integration with your existing software systems to streamline data flow and analysis. Second, invest in thorough training for your personnel to secure effective system use and data interpretation. Finally, consider a phased rollout approach, allowing for adjustments and optimization as you scale the system across your fleet.

Seamless Software System Integration

Successful implementation of fuel monitoring systems hinges on seamless software integration. When integrating these systems into your existing fleet management software, prioritize software compatibility and system scalability. Confirm that your chosen fuel monitoring solution can communicate effectively with your current systems, allowing for real-time data exchange and extensive reporting.

To achieve seamless integration, consider the following steps:

- Assess your current software infrastructure and identify potential compatibility issues

- Choose a fuel monitoring system that offers strong API capabilities for easy integration

- Develop a detailed integration plan, including data mapping and transfer protocols

- Conduct thorough testing to confirm smooth data flow and system performance

Training Personnel Effectively

Effective personnel training is essential for the successful implementation of fuel monitoring systems. To guarantee staff engagement and maximize system efficiency, you'll need to employ various training methods customized to different learning styles and job roles. construction fleet anti-theft measures - construction vehicle fuel management solutions. Develop an all-encompassing training program that covers system operation, data interpretation, and troubleshooting

| Training Method | Advantages | Best Suited For |

|---|---|---|

| Hands-on workshops | Practical experience | Technicians |

| Online modules | Self-paced learning | Office staff |

| Simulation exercises | Risk-free practice | Drivers |

| Mentorship programs | Personalized guidance | New hires |

Focus on safety protocols and best practices throughout the training process. Emphasize the importance of accurate data entry and regular system maintenance to guarantee reliable fuel monitoring. Conduct periodic refresher courses to keep your team up-to-date with system upgrades and new features.

analyzing construction fleet performance to cut costs

analyzing construction fleet performance to cut costsTo measure training effectiveness, implement performance assessments and gather feedback from trainees. Use this data to continuously improve your training program and address any knowledge gaps (track and manage construction fleet fuel usage). construction fleet anti-theft measures. By investing in all-encompassing personnel training, you'll maximize the benefits of your fuel monitoring system, enhance operational efficiency, and promote a culture of safety and accountability within your construction fleet

Phased Rollout Approach

Implementing a fuel monitoring system across your entire construction fleet can be overwhelming. A phased rollout approach allows you to systematically introduce the technology, ensuring a smoother shift and minimizing disruptions to your operations. Start with pilot testing on a small subset of vehicles, gathering user feedback and addressing any issues before expanding. This method enables you to fine-tune the system and build confidence among your team.

To execute a successful phased rollout:

- Select a representative sample of vehicles for initial deployment

- Train operators and managers on the new system's features and benefits

- Collect and analyze data from the pilot phase to identify areas for improvement

- Gradually expand implementation based on lessons learned

construction fleet fuel cost management

construction fleet fuel cost managementOvercoming Common Challenges

While fuel monitoring systems offer significant benefits, they come with their own set of challenges. You'll need to address data accuracy issues by regularly calibrating sensors and cross-checking reports. Make certain your chosen system has a user-friendly interface to maximize adoption and minimize training time. Consider the cost implications of implementation, including hardware, software, and ongoing maintenance expenses.

Maintenance challenges can arise, so establish a routine inspection schedule and train staff on troubleshooting procedures. Stay informed about regulatory compliance requirements, as fuel monitoring may intersect with emissions reporting or safety regulations. construction fleet anti-theft measures. To facilitate technology adoption, involve key stakeholders early and communicate the system's benefits clearly

Careful vendor selection is essential; evaluate providers based on their track record, customer support, and system compatibility with your existing fleet. Be prepared to address employee resistance by emphasizing how the system enhances safety and efficiency rather than micromanaging. Implement a clear policy on data usage and privacy to alleviate concerns. read more about it. By proactively addressing these challenges, you'll maximize the effectiveness of your fuel monitoring system and realize its full potential for improving fleet management

construction fleet fuel cost management

construction fleet fuel cost managementFuture Trends in Fuel Monitoring

Three key trends are shaping the future of fuel monitoring in construction fleets: advanced data analytics, integration with predictive maintenance systems, and real-time optimization algorithms. These developments will enhance efficiency, reduce costs, and improve safety across your operations.

Data analytics will provide deeper understanding into fuel consumption patterns, enabling you to make data-driven decisions for route optimization and vehicle assignment. Predictive maintenance integration will help prevent fuel-related breakdowns, ensuring your fleet's reliability and minimizing downtime.

reduce operating expenses with fleet fuel management

reduce operating expenses with fleet fuel managementReal-time optimization algorithms will continuously adjust fuel usage based on current conditions, maximizing efficiency and reducing waste. construction fleet anti-theft measures. You'll benefit from:

- Improved fuel economy by up to 15%

- Reduced maintenance costs by predicting issues before they occur

- Enhanced safety through early detection of potential fuel system failures

- Increased productivity with optimized route planning and vehicle utilization

To stay competitive, you'll need to adopt these trends. Invest in systems that offer advanced analytics capabilities, integrate with your existing maintenance software, and provide real-time optimization features. By doing so, you'll position your construction fleet for improved performance, reduced operating costs, and enhanced safety in the years to come.

Frequently Asked Questions

How Much Does a Typical Fuel Monitoring System Cost?

You'll find fuel monitoring systems typically cost $500 to $2,000 per vehicle, depending on system features. Don't forget to factor in installation costs, which can range from $100 to $500 per unit. Prices vary based on complexity and functionality.

Can Fuel Monitoring Systems Detect Fuel Theft?

These systems are your ticket to fuel theft prevention. They'll keep an eagle eye on your fuel usage analytics, spotting any unexpected disappearances. You'll quickly identify discrepancies, ensuring your fleet's efficiency and safety remain excellent.

Are There Any Legal Requirements for Implementing Fuel Monitoring Systems?

You'll find that legal requirements for fuel monitoring systems vary by location. However, implementing them often helps you meet industry standards and guarantee legal compliance. They're also beneficial for safety and efficiency in your operations.

How Often Should Fuel Monitoring Systems Be Calibrated or Maintained?

Did you know 75% of fuel monitoring issues stem from poor maintenance? You should calibrate your systems quarterly and follow a strict maintenance schedule. construction fleet efficiency and cost reduction. It'll guarantee accuracy, prevent fuel theft, and enhance efficiency - construction fleet anti-theft measures. Don't overlook this vital safety measure

Can Fuel Monitoring Systems Be Retrofitted to Older Construction Equipment?

You can retrofit fuel monitoring systems to older equipment, but consider retrofitting challenges and equipment compatibility. It's essential to assess your fleet's needs, evaluate system requirements, and guarantee proper installation for safe and efficient operation.

Conclusion

You've now got the tools to make informed decisions about fuel monitoring systems for your construction fleet. Remember, "knowledge is power," and this power translates directly to cost savings. construction fleet anti-theft measures and efficiency gains. By implementing the right system, you'll streamline operations, reduce fuel waste, and enhance your bottom line. Stay ahead of the curve by keeping an eye on emerging trends. It's time to take control of your fleet's fuel consumption