Perhaps among the most universal and versatile sorts of plastic piping, PVC pipelines have remained in usage for over 80 years, servicing a plethora of applications in numerous market industries around the world. Compared to steel piping, PVC pipelines are incredibly strong and resilient, with complete rust resistance and with little danger of catching thermal expansion or contraction. Economical and durable, these pipelines can be found in various sizes with a series of readily available installations and can be used for both warm and cold water applications depending upon the sort of PVC version.

What is PVC Pipe Utilized For?

PVC pipelines are frequently utilized for manufacturing sewer pipes, water pipe and irrigation. Having really lasting properties, PVC pipelines are simple to mount, lightweight, solid, resilient and easily recyclable, making them inexpensive and lasting. The smooth surface area of PVC pipelines additionally encourages faster water flow due to lower quantities of rubbing than piping made from various other products such as cast iron or concrete. PVC pipelines can also be produced to differing lengths, wall thicknesses and diameters, according to international sizing standards such as cacophony 8061, ASTM D1785 and ASTM F441.

How are PVC Pipeline Made?

PVC pipelines are produced by extrusion of basic material PVC, and usually comply with the exact same steps of typical pipe extrusion operations:

- Feeding of raw material pellets/ powder right into the PVC twin screw extruder

- Melting and home heating in numerous extruder areas

- Squeezing out via a die to form right into a pipeline

- Air conditioning of the shaped pipe

- Reducing of PVC pipelines to the preferred size

Although it adheres to a comparable production procedure as most plastic extrusion machines, PVC pipelines have intrinsic features that present added challenges to pipe makers both in terms of production, as well as positioning their items on the marketplace. The Challenges of best PVC pipe manufacturing.

Increased Extruder Friction

As a result of the nature of PVC plastic, PVC extruders are subjected to high quantities of friction and tension. This implies that to assure a long life span, PVC pipe assembly line call for the use of specialized extruders that utilize a twin screw extruder configuration, along with including robust building products that can hold up against the rough PVC extruder operating conditions.

Differentiating From Competitors

Because PVC piping is one of one of the most pre-owned types of piping, there is a lot of competitors in between makers. It is consequently of extremely important importance for PVC pipe manufacturers to differentiate themselves from their rivals, both in terms of delivering constant product top quality, along with using a wide variety of items at competitive rates. Such differentiation can only be achieved through using top quality manufacturing devices that takes full advantage of efficiency while decreasing expenses and has the capability to create a wide variety of PVC pipe sizes. NEO PLAST uses a series of effective turnkey solutions that guarantee this sort of effective operation, such as devices with incorporated Sector 4.0 performance, progressed connectivity, ease of assimilation and multi-layer die heads that take full advantage of cost savings.

Providing a Comprehensive Product Range

PVC pipes been available in different sizes and sizes, and for every dimension exists a range of installations. Consequently it is extremely desirable for PVC door window profile machine manufacturer in India to provide the marketplace with a detailed variety of products. NEO PLAST supports PVC pipe producers with a wide range of ready-made PVC pipe fittings, readily available in various kinds and sizes, assisting you bring your items to market with a full family members of PVC piping products.

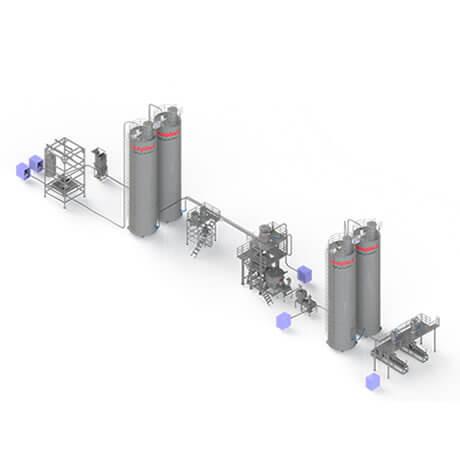

NEO PLAST PVC Pipe Production Lines

NEO PLAST offers full turnkey assembly line for PVC pipe production. Twin screw PVC extruders come in a variety of kinds and sizes to match a selection of clients' manufacturing needs. NEO PLAST offers a range of PVC assembly line that can produce pipes from as little as 16mm and as large as 630mm. No matter what the client requires, NEO PLAST supplies equipment and setups for all phases of the production line to guarantee the quick, reliable and trusted manufacture of PVC pipes.

Learn More with NEO PLAST

Get extra information regarding our PVC pipe assembly line and just how to come to be an independent producer right here! The third-most usually approved synthetic polymer, PVC, is created and exercised at the price of 40 million lots a year worldwide. Its central application is as a network for water in various contexts.

What is composed of, which gives it a generally desired product? The raw product utilized is polyvinyl chloride, whose number of advantageous physical and chemical homes make it the perfect choice for a safe and economical network in a spectrum of facilities applications, the major being water supply.

PVC means polyvinyl chloride. It is a chlorinated hydrocarbon polymer. In its original state, it is difficult and breakable. Yet when combined with additives such as plasticizers, it transforms a lot more flexible and flexible.

Its functions are electric insulation, medicinal tubing, flooring, fittings, signage, and rubber substitute. Yet its different preferred usage is in the production of pipelines used in water system, plumbing, and watering.

Depending upon the PVC pipe benefits, a couple of alternatives of PVC pipelines are done as hot or cold water channels in industrial and organization contexts. PVC pipe exporters have actually been making use of PVC for over 80 years for different commercial functions. PVC pipelines are made use of in numerous piping applications, from the transportation of alcohol consumption water over sewage services to innovative fire-sprinkler systems. This reputation owes a single mix of safety, ecological performance, durability/cost-efficiency, and recyclability.

PVC pipes are safe

PVC pipelines are a dependable choice for the transport of alcohol consumption water. This is owed to their high degree of inertness and opposition to rust. PVC pipes are consequently run away from the bio-film infection that can be a breeding place for microorganisms. By sustaining give clean water, PVC pipe benefits public health.

Throughout the framework, the European PVC and piping organization has actually targeted to change undesirable points. Therefore, the replacement of lead-based stabilizers in evident PVC compounds was integrated in 2015. Since it is exercised listed below its glass improvement temperature (80 ° C), PVC can be considered an useful block is stopping any type of low molecular density materials from relocating to drinking water. Activity tests have actually shown movement levels much below the exploration restriction of one of the most modern analytical techniques.

PVC pipes are solid & cost-efficient

The initial PVC piping approaches were developed over 80 years, and the majority of are still being used. The average life expectancy of a PVC pipe is 100 years or more for hidden pipes. Moreover, PVC piping techniques show a much deeper failure rate than other components. When seen over their whole lifetime, PVC pipes are likewise the most inexpensive choice compared to various other piping components. This includes the expenses to purchase pipes, mount, handle and regulate and take down the pipe. Year security and low complete cost of control suggest syndicates can safely prefer PVC for their piping infrastructure.

PVC pipes are the most effective option for the environment

PVC pipes have unique ecological benefits over old materials. As PVC is a cheap carbon plastic, PVC pipelines need less energy and fewer products to make. As a result of their less weight, low power is made use of when delivered. PVC pipes offer long with a shadow of preservation, and they are conveniently recyclable Several modern-day PVC pipes consist of recycles, as an example, three-layer lines where the center layer is constructed from recycled PVC. Moreover, the ultra-smooth covering of PVC pipes reduces pumping expenses and power usage, and their leak-free fittings decrease water loss. This benefits both the setting and the solution bill.

PVC pipes are recyclable.

PVC pipes are readily recyclable and can be recycled sometimes without investing their technological attributes. Each year around 80,000 weights of PVC pipes are recovered in Europe with the neoplast program. This recycle is used to develop new pipelines and a combination of other PVC products. Traceability and qualification systems for recycles guarantee a high level of safety and security and quality for recycled PVC.

Why choose us Neoplast Engineering Private Limited

Neoplast offers leading course powder conveying system solutions tailored to enhance product handling. As a leading pneumatic conveying system manufacturer, we ensure smooth and efficient material transfer for your procedures. In addition, in Ahmedabad, explore our advanced PVC suction hose machine designed to provide high-quality hose production. Trust Neoplast for advanced services that enhance your manufacturing processes.