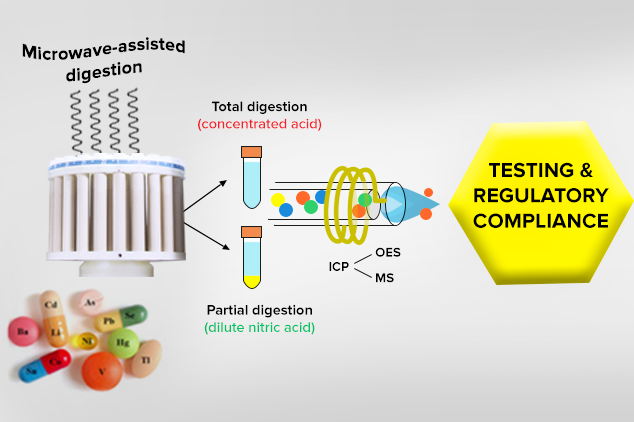

Microwave digestion is one of the most commonly used industrial technique for sample preparation during Atomic Absorption (AA) and Inductively Coupled Plasma (ICP) analyses. In microwave digestion, the combination of the sample matrix (components other than the analyte of interest) and acid is heated up to 260°C in a pressurized container. Microwave heating under high pressure breaks the sample molecules faster and dilutes them into a solution.

The other advantage of microwave assisted digestion is that the sample is heated evenly within the shortest possible time. This avoids the loss of test elements in vapor and provides the best quality samples for further analysis.

Microwave assisted digestion requires less acid which reduces the risk of contamination from external sources. Temperature and pressure monitoring are essential for safe and efficient microwave digestion.

Relevance of Temperature Monitoring during Microwave Assisted Digestion

Accurate temperature monitoring and control becomes very important in microwave assisted digestion because of the rapidly changing temperatures during the process. The various kinds of test samples require varying temperature for digestion. In the absence of an adequate temperature setting and control, the digestion results may not be accurate and reliable.

Fiber Optic Temperature Sensors for Microwave Digestion

One interesting fact about fiber optic temperature sensors is that they can survive aggressive acids, temperatures ranging up to 260°C and they have excellent insulation capacity (dielectric properties).

Fiber optic temperature sensors are the safest sensors to measure temperature under radiofrequency and microwave environments. The sensors can be installed inside the microwave digestion reactors to measure the direct sample temperature during the digestion process. Unlike metal sensors, these sensors do not create sparks inside of microwaves.

As a manufacturer, we have industrialized the Gallium Arsenide (GaAs) fiber optic sensing technology as a temperature monitoring solution. We provide a wide range of fiber optic temperature sensors such as LSENS-P, LSENS-T and LSENS-R which are chemically inert and immune to microwave environments. Due to lower thermal mass, these sensors are fast, responsive and accurate.

Our fiber optic temperature sensors are corrosion resistant and do not contaminate the digestion samples. The sensors are designed for measuring temperature under the high-pressure environment of the microwave digestion reactor. The customized mounting options are being provided to customers based on their microwave design