What is the Use of Machine Shaft in Everyday Machinery Application?

Machine shafts play a crucial role in everyday machinery across various applications. Here are some key points illustrating their significance:

Transmission of Power

Machine shafts are essential for transmitting rotational power from one part of a machine to another. For instance, in engines, turbines, or even simple mechanical devices like drills or fans, shafts transfer rotational energy generated by motors or engines to the components that perform useful work.

Support and Stability

Shafts provide structural support and stability to rotating components. They ensure that rotating parts such as gears, pulleys, and wheels remain aligned and function smoothly. Proper alignment and support prevent excessive vibration and wear, thereby extending the life of the machinery.

Versatility in Design

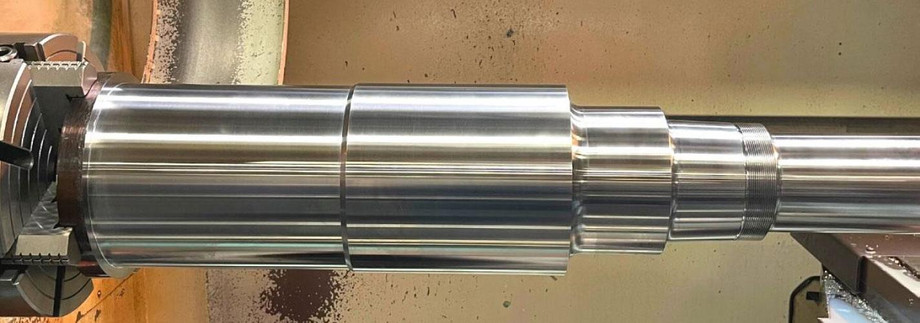

Shafts come in various shapes, sizes, and materials depending on their specific application. They can be straight or tapered, solid or hollow, and made from materials ranging from steel and aluminum to advanced alloys or composites. This versatility allows engineers to tailor shaft designs to meet specific performance requirements.

Critical Components in Complex Systems

In complex machinery such as industrial robots, CNC machines, or aerospace equipment, shafts often serve as the backbone of mechanical systems. Their precise design and manufacturing are crucial to ensure the overall efficiency, reliability, and safety of the equipment.

Maintenance and Durability

Proper maintenance of shafts is essential for the longevity and efficient operation of machinery. This includes regular lubrication, inspection for wear or misalignment, and occasional replacement when necessary. Durable shaft materials and coatings can also enhance resistance to corrosion, fatigue, and other forms of degradation.

Innovations in Shaft Technology

Advancements in materials science and manufacturing techniques continue to drive innovations in shaft design. For example, the use of carbon fiber-reinforced polymers (CFRP) or ceramic materials can reduce weight and improve performance in high-speed or high-stress applications.

Safety Considerations

Shafts must be designed with safety in mind, especially in environments where they may operate under high loads or speeds. Failures in shafts can lead to catastrophic failures in machinery, posing risks to operators and surroundings.

Conslusion

Overall, machine shafts are fundamental components in the operation of everyday machinery, enabling power transmission, ensuring stability, and supporting the overall functionality and safety of various mechanical systems. Their design, material selection, and maintenance are critical factors in optimizing performance and reliability across different industrial and consumer applications.