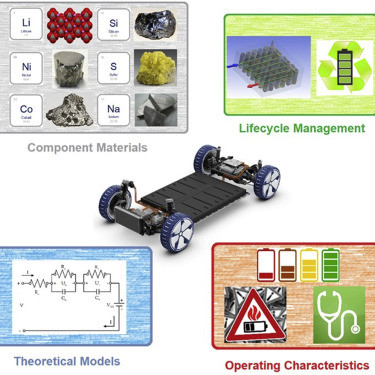

Designing battery packs with thermal uniformity in mind is a crucial aspect of modern energy storage systems, especially for applications in electric vehicles (EVs), renewable energy, aerospace, and portable electronics. As the demand for higher performance, safety, and longevity in battery systems continues to grow, engineers and manufacturers must prioritize how heat is managed within a battery pack. A thermally uniform battery pack ensures each cell operates within an optimal temperature range, which EV Thermal Management influences overall efficiency, safety, and service life.

Lithium-ion batteries, which are widely used in most current battery-powered technologies, are sensitive to temperature changes. When cells within the same pack operate at significantly different temperatures, the imbalance can lead to uneven aging, capacity loss, and in extreme cases, thermal runaway. This phenomenon occurs when a single overheated cell triggers a chain reaction, potentially leading to catastrophic failure. Therefore, maintaining a consistent temperature across all cells is not merely about performance—it’s about safety and reliability.

Achieving thermal uniformity begins with the physical layout of the battery cells. Whether cylindrical, prismatic, or pouch cells are used, how they are arranged significantly impacts how heat is distributed and dissipated. Cells positioned near the center of a dense cluster often retain more heat than those at the periphery. Designers must consider not just the electrical layout but also airflow paths, cooling interfaces, and structural materials that can either retain or release heat efficiently. Utilizing thermal simulation tools during the design stage helps predict hot spots and allows for structural adjustments before prototyping.

Another essential factor is the cooling strategy employed. There are several types of thermal management systems commonly used in battery pack design: air cooling, liquid cooling, phase-change materials, and heat pipes or vapor chambers. Each method has advantages and limitations, and choosing the right approach depends on the application. For instance, air cooling may suffice for low-power applications but becomes inefficient in high-energy-density systems due to its limited thermal conductivity. Liquid cooling systems, by contrast, are far more effective in transferring heat away from critical areas but add complexity and weight. Integrating coolant channels between cells or within the battery tray can promote thermal uniformity and allow for faster heat transfer.

The use of advanced materials also plays a pivotal role in thermal management. Thermal interface materials (TIMs) are used between battery cells and cooling plates to eliminate air gaps and ensure uniform contact, thereby improving the efficiency of heat transfer. Additionally, composite materials with high thermal conductivity and electrical insulation properties can be used in module housings or barriers to maintain cell separation while enabling better heat spreading. These materials ensure that no single cell becomes significantly hotter than the others, maintaining uniform performance across the pack.

Thermal sensors and smart battery management systems (BMS) further enhance the ability to manage temperatures. A well-calibrated BMS monitors the temperature of individual cells or cell groups in real-time and adjusts the thermal management strategy accordingly. If one area of the pack begins to overheat, the BMS can activate cooling mechanisms or adjust the load to balance temperatures. This active management helps prevent localized hot spots and extends the lifespan of the battery pack.

It is also important to consider the thermal properties of the environment in which the battery will operate. For EVs, for instance, external temperatures can vary widely depending on location and season. A good thermal design will account for these external conditions and include heating mechanisms for cold climates and efficient cooling for hot ones. Integrating insulation layers within the battery enclosure helps reduce the influence of ambient temperature fluctuations, ensuring thermal stability regardless of operating conditions.

Testing and validation are final but critical steps in ensuring thermal uniformity. Engineers use thermal imaging, temperature probes, and simulation data to verify that their designs function as expected under real-world conditions. Pack prototypes are subjected to various load cycles, environmental conditions, and failure scenarios to test how well the system maintains temperature uniformity. Based on test results, further refinements are made to ensure performance and safety goals are met.

In conclusion, designing battery packs with thermal uniformity in mind is a multi-disciplinary effort that combines engineering design, material science, thermal dynamics, and system-level control. As batteries become more integral to our everyday lives—from powering electric vehicles to storing solar energy—ensuring they operate safely and efficiently is more important than ever. Thermal uniformity not only extends battery life but also boosts system reliability and safety, making it a foundational element of modern battery design strategy.