Market Overview

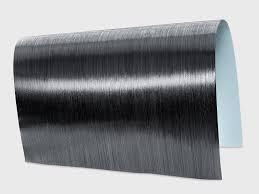

Carbon prepreg refers to a composite material in which carbon fibers are pre-impregnated with a resin system often epoxy offering designers precision in fiber orientation and resin content. These prepregs deliver exceptional strength-to-weight ratios, superior stiffness, corrosion resistance, and improved fatigue life compared to traditional composites.

Industries such as aerospace and defense leverage carbon prepregs for critical structural components wing skins, fuselage panels, and interior fittings where lightweight and high mechanical performance are paramount. In automotive applications, electric vehicle manufacturers employ carbon prepregs to enhance range and safety, while renewable energy developers integrate them into wind turbine blades to boost efficiency and reduce maintenance.

The Carbon Prepreg Market is estimated to be valued at USD 10,071.1 Mn in 2025 and is expected to reach USD 18,660.1 Mn in 2032, exhibiting a compound annual growth rate (CAGR) of 9.21% from 2025 to 2032.

Key Takeaways

Key players operating in the Carbon Prepreg Market are ACP Composites Inc., Kordsa Teknik Tekstil AS, Barrday, Gurit, Hexcel Corporation, and Lingol. These market players have established robust global footprints, leveraging advanced R&D capabilities to introduce high-performance resin formulations and tailored fiber architectures. By aligning product portfolios with stringent aerospace and automotive specifications, these companies sustain competitive market share, drive market growth strategies, and respond swiftly to emerging market challenges.

Carbon Prepreg Market demand arise from expanding applications in renewable energy and consumer electronics. The demand for lighter, stronger wind turbine blades and compact, durable housings for smartphones and laptops presents lucrative prospects. Adoption of automated layup and hot-melt prepreg processes is gaining traction, promising cost efficiencies and higher throughput. Furthermore, growing interest in electric aircraft and hydrogen-powered vehicles opens new avenues for carbon prepreg utilization, underscoring untapped market opportunities in emerging segments.

Market Drivers

One of the primary market drivers for the Carbon Prepreg Market is the escalating demand from the aerospace and defense sector. As airlines and military organizations prioritize fuel efficiency, performance, and reduced life-cycle costs, carbon prepregs have become indispensable for manufacturing next-generation aircraft structures. The ability to precisely control fiber orientation and resin content ensures that components meet rigorous safety and performance standards, thereby driving business growth.

Additionally, regulatory pressure to lower carbon emissions compels aircraft manufacturers to adopt lightweight materials, further amplifying market drivers. Innovations in resin chemistry such as toughened epoxies and out-of-autoclave systems enhance processing efficiency and lower production costs, making carbon prepregs increasingly attractive for large-scale operations. Collectively, these factors in market demand and technological advancements are propelling the carbon prepreg industry toward sustained growth throughout the forecast period.

PEST Analysis

Political: Strong regulatory frameworks governing aerospace, automotive and wind energy applications drive adoption of advanced prepreg solutions. Trade agreements and import-export tariffs on carbon-based materials shape supply chains, influencing where manufacturing hubs establish operations. Government incentives for defense modernization and infrastructure upgrades further bolster demand through supportive funding.

Economic: Volatility in raw material pricing, particularly epoxy resins and carbon fibers, affects production costs and profit margins. Currency fluctuations and shifts in global oil prices indirectly impact manufacturing overheads. Economic recovery programs and infrastructure spending packages in key regions create favorable conditions for business growth and capital investment.

Social: Growing consumer preference for lightweight, fuel-efficient vehicles and eco-friendly public transport amplifies demand for carbon prepreg composites. Heightened awareness of carbon footprint reduction and sustainability initiatives encourages adoption in sporting goods and high-performance sectors. Workforce skill development programs support a pipeline of technicians trained in advanced composite manufacturing.

Technological: Rapid innovations in automated fiber placement and resin transfer molding enhance production efficiency and part consistency. Continuous research into high-temperature resin systems and novel fiber architectures expands performance thresholds, enabling broader end-use applications. Advances in digital twin technology and predictive maintenance offer improved quality control and reduced scrap rates.

Geographical Regions with Highest Value Concentration

North America and Europe account for the largest market share in the carbon prepreg sector, driven by robust aerospace, defense, and automotive industries. The United States remains a leading hub thanks to extensive R&D investments and a mature manufacturing ecosystem, while Germany and France benefit from strong industrial clusters and established supply networks. Market research highlights that these regions collectively contribute over half of total industry revenue, supported by long-standing collaborations between major aircraft OEMs and composite suppliers.

In Europe, the emphasis on next-generation commercial jets and high-speed rail projects sustains healthy demand, reflecting evolving market trends toward lightweight structures. Meanwhile, mature aftermarket services and refurbishment programs reinforce steady business growth, with rising interest in composite repair solutions. These developed economies also exhibit significant investment in market opportunities related to renewable energy, where wind turbine blade manufacturers increasingly turn to prepreg systems for enhanced fatigue resistance.

Get this Report in Japanese Language

Get this Reports in Korean Language

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/ )