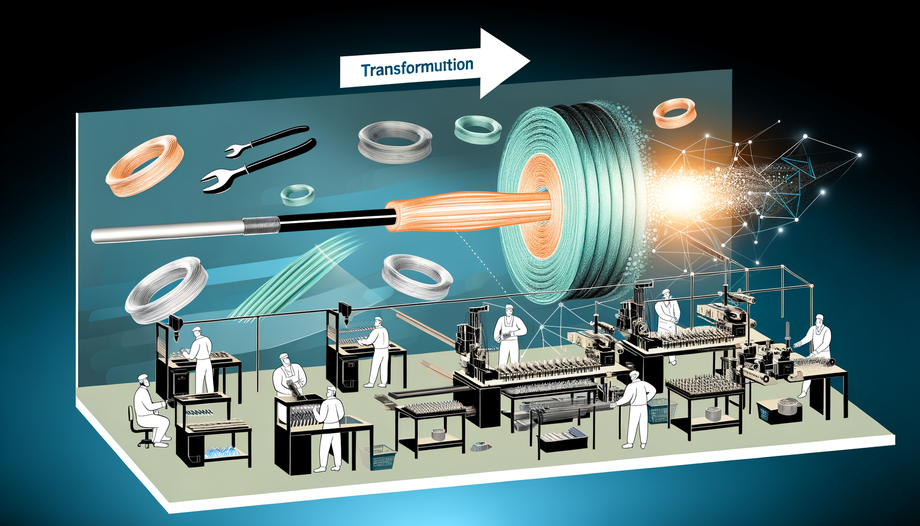

The landscape of electric cable manufacturing is undergoing a revolutionary transformation. Emerging technologies and innovative practices are redefining the way we produce these vital components, which form the backbone of our modern infrastructures. From high-tech machinery to sustainable practices, the industry is witnessing significant advancements that promise to enhance efficiency, safety, and sustainability. Let's delve into the key enablers driving this change.

1. Automation and Robotics

Gone are the days when manual labor dominated the production lines. Today, automation and robotics are at the forefront of the manufacturing process, offering unparalleled precision and efficiency.

-

Smart Robotics: Cutting-edge robotic systems are capable of performing complex tasks with high accuracy. These include wire drawing, insulation, and cabling, reducing the likelihood of human error.

-

Automated Quality Control: Advanced machines equipped with AI-run inspection systems ensure defect detection in real time, minimizing waste and maintaining quality standards.

2. IoT-Enabled Smart Factories

The Internet of Things (IoT) has paved the way for creating interconnected smart factories. This technological advancement allows for streamlined operations and better decision-making.

-

Predictive Maintenance: IoT devices monitor equipment health, predicting failures and scheduling maintenance promptly, leading to reduced downtime.

-

Data Analytics: Real-time data collection and analysis provide insights into production efficiency and potential improvements.

3. Sustainability and Eco-friendly Practices

Modern cable manufacturers are embracing green innovations, making strides toward more sustainable production.

-

Recycled Materials: Utilizing recycled metals and plastics not only helps conserve resources but also reduces production costs.

-

Energy-efficient Processes: Implementing energy-efficient heating and cooling systems conserves energy and reduces environmental impact.

4. Advanced Materials Development

Material science is constantly evolving, facilitating the creation of cables that are stronger, lighter, and more durable.

-

Lightweight Conductors: New composite materials are reducing weight without compromising electrical capabilities.

-

Enhanced Insulation Materials: Advanced polymers and ceramics offer superior insulation and resistance properties.

5. 3D Printing Innovations

3D printing technology is beginning to leave a mark on cable manufacturing. This technology offers customization and rapid prototyping.

-

Prototyping and Customization: Quick production of prototypes helps identify and eliminate design flaws early in the process.

-

Component Fabrication: Creating complex cable parts and connectors is more feasible and efficient with 3D printers.

6. Collaborative Manufacturing Networks

Networking and collaboration among manufacturers and suppliers create a more robust and responsive supply chain.

-

Shared Resources and Expertise: Collaborative networks promote the exchange of technology and expertise, fostering innovation.

-

Flexibility and Resilience: Wide-reaching networks help manufacturers respond swiftly to market changes and demands.

Conclusion

The electric cable manufacturing sector is witnessing a remarkable transformation driven by technology and innovation. Automation, IoT, sustainability, advanced materials, and 3D printing are revolutionizing the industry, giving rise to smarter and more efficient production lines. In this dynamic landscape, embracing these changes is not just an option but a necessity. By doing so, manufacturers can look forward to addressing the challenges of tomorrow while remaining competitive in a rapidly evolving market.

Whether we speak of integrated operations or sustainability-focused strategies, it's evident that the future shines bright for electric cable manufacturers who dare to innovate. Let's stay at the forefront of these advancements, ensuring a more efficient, sustainable, and electrifying future for our industry.

Explore Comprehensive Market Analysis of Electric Cable Production Line Market

SOURCE -- @360iResearch