In a world where precision and efficiency dictate the future of automotive manufacturing, it is vital to explore how critical innovations in single vertical balancing machines are reshaping this sector. These advanced devices are transforming the dynamics of automotive production, promising better performance, safety, and durability. Let's delve into the pivotal shifts in technology contributing to the evolution of single vertical balancing machines, offering an intriguing lens to the modern auto industry.

Understanding Vertical Balancing Machines

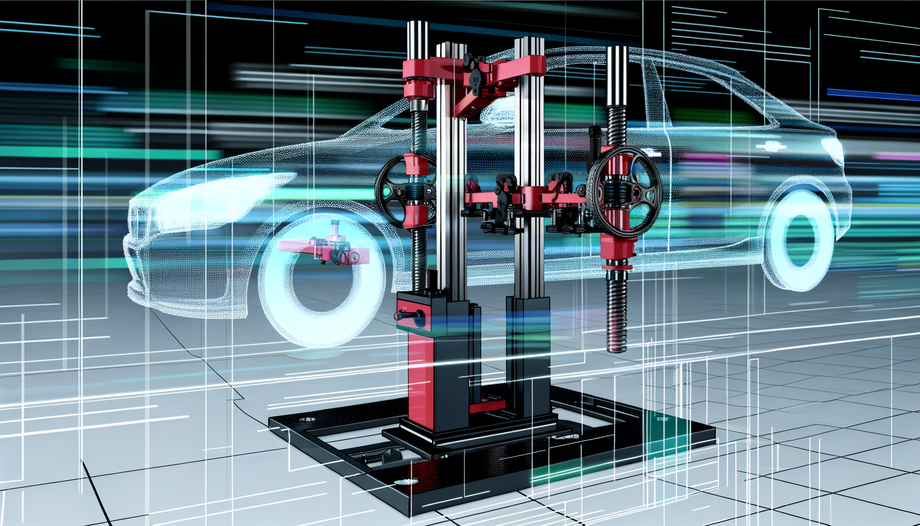

Vertical balancing machines are cutting-edge equipment designed to optimize the balance of rotating parts, vital in vehicle manufacturing. Their precise engineering minimizes rotational vibrations that can lead to mechanical failures, offering a smoother driving experience. Traditionally, such devices are used in a variety of components – from brake discs to crankshafts – each requiring meticulous precision.

Why Balance is Crucial in Automotive Parts

Dynamic imbalance in vehicle components can lead to catastrophic failures, causing suboptimal performance, increased wear, and even safety hazards. Addressing these imbalances extends the lifecycle of components, enhances fuel efficiency, and maintains the overall integrity of the vehicle.

Critical Innovations Driving Advancements

The landscape of single vertical balancing machines is witnessing pioneering strides rooted in three main technological advancements:

1. Digital Twin Integration

Digital twin technology stands as a transformative force in the realm of balancing machines by creating a virtual replica of the physical component. This innovation allows engineers to simulate, test, and refine parts during the manufacturing phase, identifying potential imbalances without physical prototypes, fostering real-time improvements and cutting costs dramatically.

2. Advanced Machine Learning Algorithms

Machine learning introduces self-optimizing systems, wherein machines adaptively learn from past measurements to enhance balancing accuracy. Leveraging massive data sets, these intelligent systems predict and rectify imbalances before components are physically engaged in manufacturing—heralding a new era of precision.

3. Real-time Feedback Systems

Real-time feedback mechanisms have seen an overhaul, incorporating advanced sensors and Internet of Things (IoT) devices. This technology provides continuous live updates to engineers, minimizing deviations and significantly improving quality assurance.

The Impact on Automotive Manufacturing

With precision so deeply tied to vehicle safety and performance, the integration of these innovations influences several aspects:

- Enhanced Durability: Significantly diminished vibrations lead to an increase in the durability of vehicle components, reducing the frequency and cost of maintenance.

- Improved Safety Standards: Balancing precision directly correlates with higher safety standards, potentially minimizing road accidents by ensuring all components function optimally.

- Eco-friendly Production: Efficient machines contribute to sustainable manufacturing by reducing material waste, ensuring eco-friendly processes with considerable energy savings.

Challenges in Implementation

Despite the promising outlook, the advancement of single vertical balancing machines comes with its hurdles.

- High Initial Investment: The transition to cutting-edge technology necessitates considerable financial commitments, which can be prohibitive for smaller manufacturers.

- Training & Skill Development: Industry professionals require targeted training to leverage the full potential of these advancements.

- Maintaining Intellectual Property: With technology being at the forefront, safeguarding intellectual property becomes increasingly challenging, necessitating robust security protocols.

Looking Towards the Future

As the single vertical balancing machines continue to evolve, it sets the stage for further incredible innovations tailored for specific automotive needs. By fostering collaborations and integrating new technologies, manufacturers ensure their place at the vanguard of automotive advancements. Cross-industry partnerships will be pivotal in driving cost-effective innovations, making this technology accessible across various market segments.

In conclusion, critical innovations in single vertical balancing machines are a testament to the auto industry's relentless pursuit of perfection. These technologies point to a future where vehicle performance is optimized, maintenance is simplified, and safety is paramount painting a promising picture of what lies ahead for the automotive sector. As we inch closer to this future, embracing these technological breakthroughs will determine success in the competitive auto industry landscape.

Explore Comprehensive Market Analysis of Auto Industry Single Vertical Balancing Machine Market

Source - @360iResearch