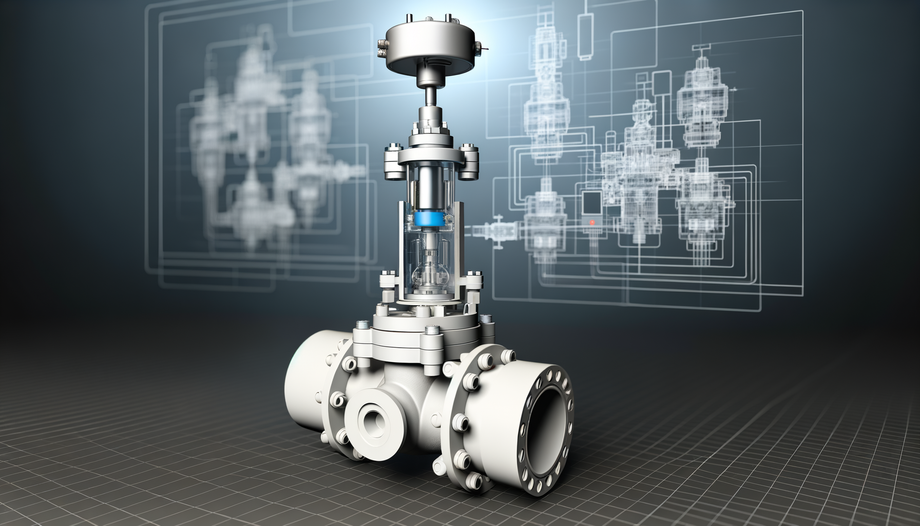

In an era where technological advancements rapidly evolve, industries across the globe are embracing automation to streamline operations, increase efficiency, and reduce costs. A crucial component in this automation journey is the valve system an integral part of controlling flow within hydraulic, pneumatic, and fluidic systems. Among the different technologies used in these applications, the solenoid unloading relief valve stands out as a pivotal device that brings both sophistication and reliability to the industrial landscape.

What's Driving the Shift Towards Sophisticated Valve Systems?

The industrial landscape is being reshaped by the demands for higher efficiency, precision, and minimal human intervention. Key factors influencing this shift include:

-

Operational Efficiency

- Automation's Role: Automated systems help achieve continuous production cycles with less downtime, ensuring high reliability and efficiency.

- Precision and Control: Improved valve systems enable precise flow control essential for optimal performance in modern machinery.

-

Cost Effectiveness

- Reduced Labor Costs: Automation reduces the need for manual intervention, resulting in lower operational expenses.

- Maintenance: Advanced valves such as the solenoid unloading relief valve require less maintenance, minimizing costs over time.

-

Technological Integration

- IoT and Connectivity: Sophisticated valve systems can integrate seamlessly with IoT-enabled devices, providing remote monitoring and real-time data analytics.

- Smart Systems: Facilitates predictive maintenance, reducing unexpected downtimes.

Solenoid Unloading Relief Valve: A Game Changer in Industrial Automation

The solenoid unloading relief valve is designed to offer solutions to common challenges faced by industries. Here’s how:

-

Pressure Management

- The valve operates by relieving excess pressure from systems, maintaining the desired operation levels, thus preventing equipment failure.

- Its automated adjustment capabilities contribute to the seamless functioning of high-pressure systems in industrial settings.

-

Versatility

- These valves are robust and versatile, adaptable across different industries such as manufacturing, oil and gas, and chemical processing.

- They support a wide range of applications from controlling hydraulic systems to air and water circuits.

-

Enhanced Safety

- Ensures safety by preventing pressure build-up which can lead to equipment damage or catastrophic failures.

- Provides operators peace of mind knowing that their systems are operating within safe pressure parameters.

Real-World Applications and Benefits

Manufacturing Sector: In manufacturing, the precision of solenoid valves translates to improved product quality, efficient assembly lines, and increased throughput. These valves cater to complex instrumentations and require minimal manual adjustment, making them ideal for high-demand settings.

Oil and Gas Industry: Unloading relief valves play a critical role in this sector by managing pressures in pipelines and storage facilities, ensuring environmental compliance and resource conservation.

Chemical Processing: The chemical industry demands stringent control over system pressures to safeguard the production process and ensure the integrity of final products. Solenoid valves meet these specifications with improved response times and reduced risks associated with human error.

The Future of Valve Systems in Industrial Automation

As industries continue to evolve in the age of automation, the sophistication of valve systems will be paramount in enabling sustainable growth. Emerging technologies promise even greater advancements, including:

-

Integration with Artificial Intelligence: AI-driven control systems could leverage advanced algorithmic models to anticipate system changes and autonomously adjust valve operations for peak efficiency.

-

Green Technologies: By optimizing energy use and minimizing waste, future valve designs aim to contribute to the development of environmentally friendly industrial solutions.

Conclusion: The integration of advanced valve systems like the solenoid unloading relief valve in industrial automation is no longer just a trend but a necessity. As the need for efficiency, precision, and safety continues to rise, these valves will serve as vital components of modern industrial systems. The challenge for industries now is to stay ahead by adopting these innovations, ensuring they are equipped to meet the demands of a rapidly evolving technological landscape.

Engage with Us!

We welcome your thoughts on the evolving role of valve systems in industrial automation. How has your organization embraced technological advancements in this area? Share your experiences and insights in the comments below!

Whether you're a seasoned industry veteran or a newcomer, understanding the essential role of advanced valve systems like the solenoid unloading relief valve can provide a competitive edge in today's dynamic market. Let's join the conversation and explore the exciting innovations on the horizon.

Explore Comprehensive Market Analysis of Solenoid Unloading Relief Valve Market

Source - @360iResearch