In the age of technological advancement, the precision cleaning industry is witnessing a significant shift towards sustainability and innovation. This transformation, especially in the realm of etching equipment parts, is increasingly being driven by substantial investments in research and development. The focus is clear: to develop more sustainable, effective, and efficient cleaning methods that align with the evolving demands of the global economy and environmental standards.

The Current Landscape of Precision Cleaning

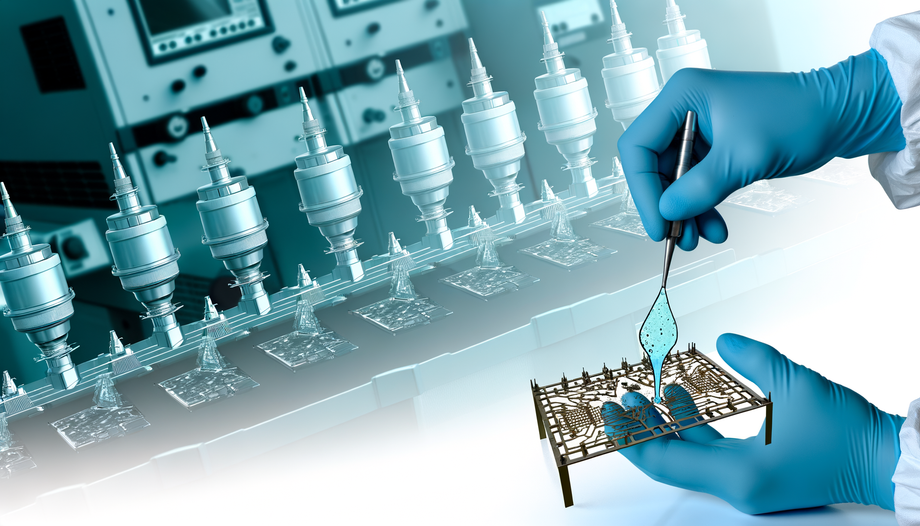

Precision cleaning is crucial in industries such as semiconductor manufacturing, aerospace, and biomedical fields. With the intricate and complex nature of etching equipment parts, any contamination that isn't meticulously eradicated can compromise operational efficiency and product quality. Historically, these cleaning processes have relied heavily on chemical solvents, many of which are neither environmentally friendly nor economically efficient.

Challenges Faced:

- Environmental Impact: Traditional cleaning methods contribute significantly to environmental pollution.

- Cost: The use of harsh chemicals can lead to high disposal and operational costs.

- Regulatory Pressure: Increasing regulations on chemical emissions and waste disposal are pushing companies to rethink their strategies.

Why Invest in R&D?

Investing in research and development presents a pathway to overcoming these challenges. Innovation in cleaning technologies promises not only to meet increasing regulatory demands but also to enhance overall operational efficiency.

Benefits of R&D Investments:

- Sustainability: Developing methods that significantly reduce or eliminate the use of harmful chemicals.

- Efficiency: Improving the effectiveness of cleaning processes for better quality control.

- Cost-Effectiveness: Reducing long-term operational costs by adopting sustainable practices.

Pioneering Innovations in the Field

Recent R&D initiatives have led to the development of several groundbreaking technologies within precision cleaning:

-

Ultrasonic Cleaning: Ultrasonic cleaning technology employs high-frequency sound waves to agitate a fluid cleaning solution, effectively dislodging contaminants without damaging the sensitive parts. This method primarily uses water-based solvents, making it an eco-friendly option.

-

Plasma Cleaning: Plasma cleaning involves the use of ionized gas to remove surface contaminants. This process is invaluable for intricate parts that require a high degree of cleanliness, offering a chemical-free alternative.

-

Supercritical CO2 Cleaning: Utilizing CO2 in its supercritical state, this method allows for effective cleaning with minimal environmental impact. It's a green solvent that can efficiently dissolve many types of contaminants.

-

Cryogenic Cleaning: Also known as dry ice blasting, this method uses CO2 pellets at extremely low temperatures to remove surface debris without causing abrasion or using chemicals.

Sustainability: The Core Driver of Innovation

The focus on sustainable solutions is not merely an ethical choice; it represents a strategic business advantage. As global companies look to minimize their carbon footprint, there is an escalating demand for eco-friendly cleaning technologies.

-

Corporate Social Responsibility (CSR): Integrating sustainable practices enhances brand reputation and regulatory compliance.

-

Circular Economy: Emphasizing sustainability in cleaning methods aids in resource preservation, facilitating a transition toward a circular economy where waste is minimized, and resources are reused.

The Road Ahead: Challenges and Opportunities

While the progress in sustainable cleaning is profoundly promising, several challenges still need addressing:

- Scalability: Ensuring that innovative cleaning methods can be implemented on a large scale without compromising effectiveness.

- Industry Adherence: Achieving widespread adoption requires strong advocacy and demonstrable benefits to industries skeptical of transitioning.

- Continuous Innovation: Ongoing investment in R&D is crucial to keep pace with the rapid advancements in etching technology.

Conclusion

The growing investment in research and development for innovative and sustainable cleaning methods marks an exciting era for the precision cleaning industry. While hurdles continue to exist, the commitment to sustainability promises immense benefits both environmentally and economically. As companies increasingly prioritize eco-friendly practices, the development of advanced cleaning technologies will undoubtedly continue to transform the landscape of etching equipment maintenance.

Explore Comprehensive Market Analysis of Precision Cleaning for Etching Equipment Parts Market

SOURCE -- @360iResearch