In a world where packaging serves as both protector and promoter of products, staying ahead in durability becomes crucial. The rise of e-commerce, global supply chains, and more environmentally conscious consumers have forced businesses to rethink how they package products. At the intersection of this shift lies a burgeoning market for innovative stress-resistance packaging testing equipment. As companies strive for resilience and efficiency, understanding the opportunities for growth in this sector is key to outpacing competition.

Unpackaging the Market Trends

Over the last decade, the packaging industry has witnessed meteoric development driven by digital transformation, heightened consumer awareness, and regulatory pressures. Yet, even amidst innovation, one fundamental need persists: durability. With the surge in online purchases and speedier delivery demands, ensuring packages withstand the rigors of transportation and handling is essential.

1. E-commerce Boom

- Volume Increase: The e-commerce industry has spearheaded a movement in which hefty volumes of products are shipped worldwide daily. Each item must arrive intact and presentably, driving the demand for robust packaging solutions.

- Custom Packaging: Personalized and custom-fit packaging experiences are emerging to cater to the unique specifications of e-commerce operators, necessitating flexible testing equipment.

2. Sustainability Revolution

- Eco-Concerns: For the eco-savvy consumer, traditional methods relying heavily on plastics fall short. Eco-friendly alternatives need rigorous testing to ensure they rival or surpass conventional counterparts in durability.

- Legislation and Compliance: Prompted by growing environmental legislation, organizations are adopting sustainable materials, demanding new testing methodologies to ensure compliance and integrity.

3. Global Supply Chains

- Diverse Condition Exposure: Global transit subjects packages to varied climatic and handling conditions, creating a need for equipment that can mimic such environments for accurate testing.

- Multimodal Transport: With goods often switching between air, sea, and road, the assortment of potential impacts needs comprehensive testing coverage.

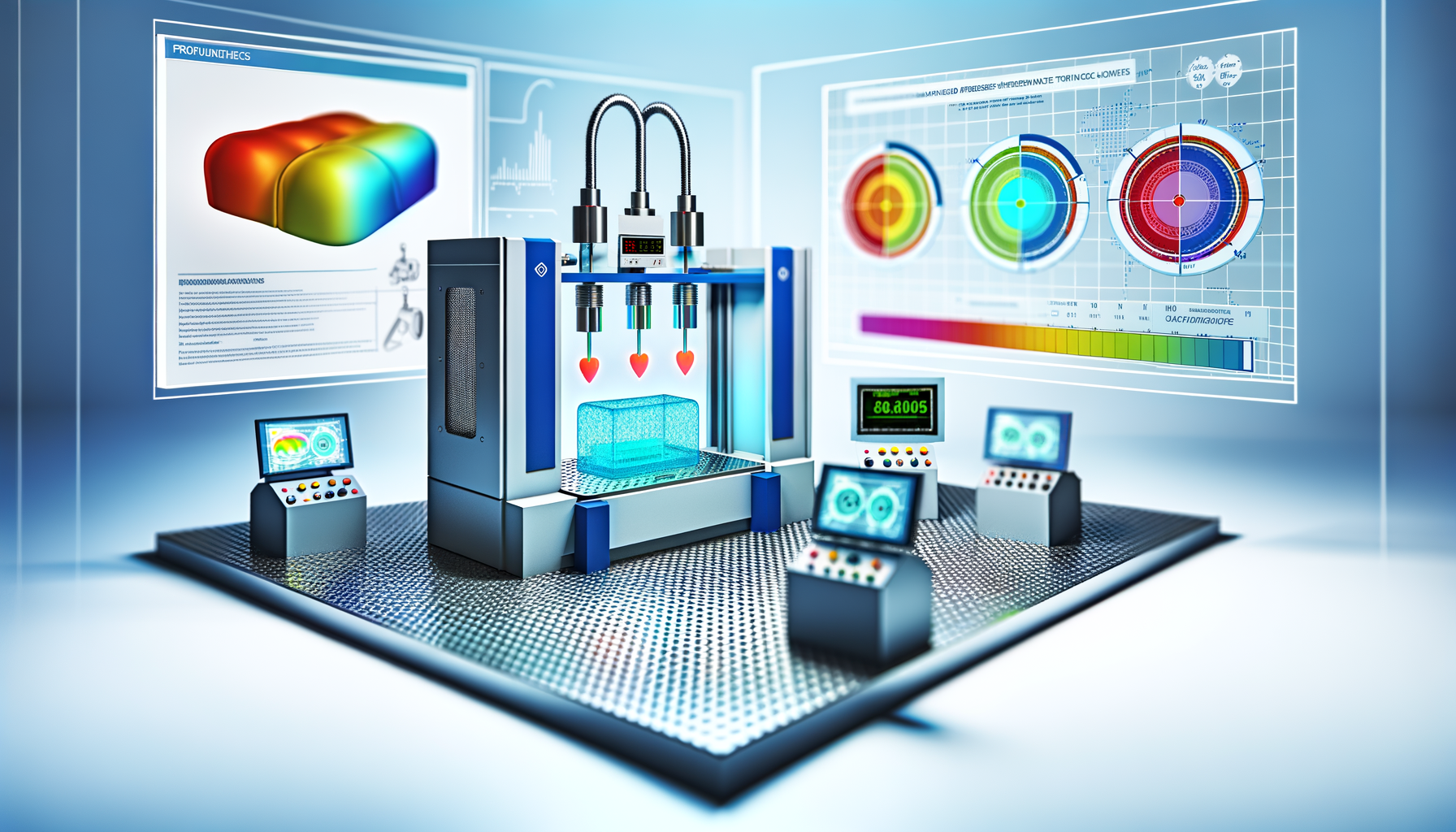

Emerging Innovations in Stress-Resistance Testing

Packaging durability testing is undergoing a renaissance fueled by advancements in technology. These innovations are making testing equipment more adaptive, precise, and efficient.

1. Smart Sensors and IoT Integration

- Real-time Monitoring: Smart sensors connected via IoT can deliver immediate feedback on packaging stress levels when integrated into testing equipment.

- Data-Driven Decisions: Data analytics enables companies to predict outcomes accurately and iteratively improve their packaging approaches over time.

2. AI and Machine Learning

- Pattern Recognition: By employing AI, stress-response patterns can be quickly identified and normalized, enhancing predictive accuracy for new designs.

- Adaptive Algorithms: Over time, AI can refine testing processes ensuring they're optimal for new materials and configurations.

3. Virtual Reality (VR) Environments

- 3D Simulations: VR can re-create the journey of a package, providing comprehensive insights into areas vulnerable to stress that might not be discovered through conventional testing.

- Quicker Development Cycles: Virtual simulations allow for rapid testing iterations, efficiently expediting the time-to-market for new packages.

Market Opportunities

Investing in advanced stress-resistance packaging testing equipment opens diverse opportunities for manufacturers, investors, and technology providers.

1. Strategic Partnerships

- Collaborative Ventures: Forming partnerships with software firms specializing in AI and VR can accelerate innovation and integrate best-in-class technology.

- Cross-Industry Engagements: Alliances with the e-commerce, logistics, and green tech sectors position firms to comprehensively address current market demands.

2. Service Expansion

- Testing as a Service: Offering subscription-based testing services can reach a plethora of smaller players within the packaging sector who may not have the infrastructure for in-house testing.

- Consultancy Roles: Beyond testing, providing insights and strategies for packaging improvements can establish firms as trusted industry leaders.

3. Competitive Edge

- Brand Authority: Becoming synonymous with reliable stress-resistance solutions can make a firm go-to choice over rivals in the industry.

- Market Differentiation: Exceptional service, bolstered by cutting-edge technology, creates differentiation that is hard for competitors to mimic.

Conclusion

The pursuit of advanced packaging durability testing equipment is teeming with potential, poised to address growing challenges and redefine industry benchmarks. As the market evolves, stakeholders who anticipate and adapt to this new landscape will position themselves as pioneers. Ultimately, leveraging innovative stress-resistance testing capabilities will not only bolster the reliability of packages worldwide but will also carve a path toward sustainable, efficient, and responsible commerce. With perceptiveness and agility, the packaging industry's future holds promise, harnessing technology in the relentless quest for resilience and excellence.

Explore Comprehensive Market Analysis of Packaging Durability Testing Equipment Market

SOURCE-- @360iResearch