|

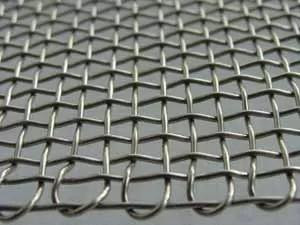

Jaiman Metalloys LLP is one of the prominent manufacturers for Alloy 316 / 316L Wire Mesh, which is a relatively rare form of corrosion which requires a very specific combination of tensile stress, temperature and corrosive species, often the chloride ion, for it to occur. Typical applications where SCC can occur in Stainless Steel 316 Hexagonal Wire Mesh are hot water tanks and swimming pools. Another form known as sulphide stress corrosion cracking (SSCC) in Stainless Steel 316L Welding Wire Mesh is associated with hydrogen sulphide in oil and gas exploration and production. This is now quite a rare form of corrosion, where if the Carbon level in SS 316 Netting Wire Mesh is too high, Chromium can combine with Carbon to form Chromium Carbide. This occurs at temperatures between about 450 Degree C – 850 Degree C in Stainless Steel 316L Woven Wire Mesh, where this process is also called sensitisation and typically occurs during welding. The Chromium available to form the passive layer in SS 316 Spring Steel Wire Mesh is effectively reduced and corrosion can occur. SS 316L Fencing Wire Mesh is avoided by choosing a low carbon grade the so-called ‘L’ grades or by using steel with Titanium or Niobium which preferentially combines by means of Carbon. Stainless Steel 316 Wire Mesh is rather like a battery and can accelerate corrosion of the less ‘noble’ metal. Supplier of ASTM SA 164 316 Stainless Steel Wire Mesh, SS UNS S31600 / S31603 Fencing Wiremesh, Stainless Steel WERKSTOFF NR. 1.4436 / 1.4404 Wire Mesh Manufacturer in India. |