Robotics is a rapidly advancing field where precision is everything. In today’s competitive technology landscape, the need for reliable, high-performance embedded hardware is more essential than ever. From industrial automation to healthcare, precision-engineered embedded systems are driving new possibilities and breakthroughs in robotics. For companies and innovators aiming to stay ahead, focusing on robust, optimized embedded hardware is the cornerstone of creating advanced, future-ready robotic solutions.

This blog explores the role of precision-engineered embedded hardware in revolutionizing robotics, emphasizing the key design principles and trends that shape today’s most innovative robotic applications.

The Foundation of Robotics: Precision in Embedded Hardware

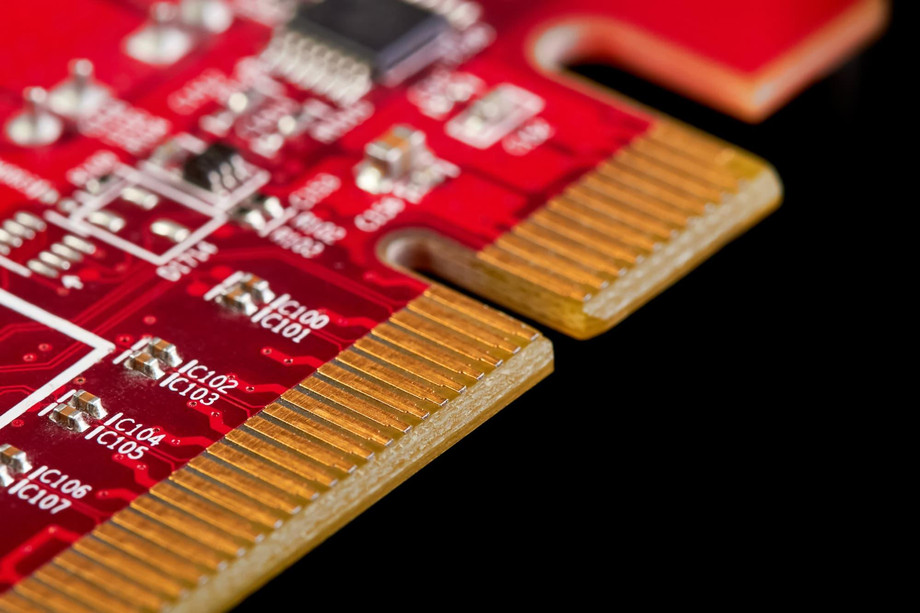

Embedded hardware is at the heart of every robotic system, integrating sensors, microprocessors, and communication interfaces to control and monitor complex functions. The hardware serves as the core infrastructure, enabling high levels of automation and machine learning capabilities. Whether it’s a robotic arm performing intricate tasks on an assembly line or autonomous drones navigating complex terrains, the quality of the embedded hardware directly impacts performance, reliability, and adaptability.

For robotics innovators, choosing the right embedded hardware is critical to achieving the high precision and seamless integration needed in today’s advanced robotic applications. High-precision embedded hardware supports enhanced data processing, faster response times, and more accurate movement control, allowing robotics to operate in ways previously unachievable.

Key Elements of Precision in Embedded Hardware Design for Robotics

Achieving precision in embedded hardware design involves several critical components that work together to meet the stringent demands of robotics.

1. High-Performance Microcontrollers and Processors

Robotic applications demand processors that can handle real-time processing with minimal latency. High-performance microcontrollers and processors are essential for controlling complex motor functions and executing machine learning algorithms. Precision-engineered embedded hardware allows these processors to perform efficiently, enabling robots to make decisions and respond to their environment in milliseconds.

2. Advanced Sensor Integration

Sensors are the “eyes” and “ears” of robotic systems. From proximity sensors to gyroscopes and accelerometers, the sensors embedded within robotic hardware provide critical data on position, movement, and surroundings. Proper integration and calibration of these sensors ensure precise and reliable data, empowering robots to operate with exceptional accuracy in various environments.

3. Efficient Power Management Systems

Power efficiency is critical for robotics, especially for autonomous systems that require extended operational times without frequent recharging. Embedded hardware with optimized power management systems ensures long-lasting performance, enabling robots to function efficiently over prolonged periods. This is particularly important in sectors like agriculture and logistics, where robots are deployed in remote or dynamic environments.

4. Robust Connectivity Solutions

For robots to interact effectively with other devices and systems, they need reliable connectivity solutions. Embedded hardware often incorporates various connectivity options, including Wi-Fi, Bluetooth, and IoT-compatible modules, to enable seamless data exchange. This connectivity ensures that robots can operate within a networked environment, a feature essential for industrial and commercial applications where robotics is integrated with other digital systems.

Emerging Trends in Embedded Hardware for Robotics

The rapid growth of robotics is fueling demand for new and innovative embedded hardware solutions that offer greater precision, efficiency, and adaptability. Here are some of the most prominent trends driving the next generation of embedded hardware in robotics.

AI-Powered Embedded Systems

Artificial Intelligence (AI) is reshaping the robotics landscape, and its integration at the embedded hardware level is unlocking new capabilities. AI-enabled embedded hardware allows robots to process large datasets in real-time, enabling advanced functions like facial recognition, natural language processing, and predictive maintenance. This trend is particularly evident in service robotics, where AI-driven embedded systems enable robots to interact intelligently with their environment and users.

Miniaturization and Compact Design

The demand for smaller, more compact robotic systems is driving innovation in embedded hardware miniaturization. Compact, high-density components allow robotic manufacturers to design smaller systems without sacrificing performance. This trend is especially relevant in sectors such as healthcare and personal robotics, where smaller, unobtrusive devices are preferred. Miniaturized embedded hardware enables robotics designers to develop portable and versatile systems suited to various applications, from surgical robots to wearable exoskeletons.

Edge Computing for Real-Time Processing

Edge computing is transforming the capabilities of embedded hardware by enabling on-device data processing. Instead of sending data to a centralized server, edge computing allows robots to process data locally, reducing latency and improving response times. This advancement is vital for applications requiring real-time decision-making, such as autonomous vehicles and industrial robots. Embedded hardware with edge computing capabilities can enhance a robot’s ability to perform complex tasks independently, making it a valuable asset in dynamic environments.

How Precision Embedded Hardware Benefits Various Robotics Applications

Precision in embedded hardware is not just a technical achievement; it’s a competitive advantage across diverse robotics applications. By optimizing embedded hardware, robotic systems can achieve greater levels of precision, reliability, and adaptability.

Industrial Automation

In manufacturing, where efficiency and accuracy are paramount, precision-engineered embedded hardware supports industrial robots in performing complex assembly tasks, quality control, and packaging. High-precision embedded systems allow robots to work alongside human operators safely and reliably, often in environments where precision tolerances are measured in microns. With the ability to operate continuously and accurately, these robotic systems are a key asset in improving productivity and reducing human error.

Healthcare Robotics

Healthcare robotics, such as surgical robots and robotic-assisted rehabilitation devices, rely heavily on precision embedded hardware to ensure patient safety and procedure accuracy. In surgical robotics, for instance, high-precision embedded hardware allows for extremely precise control over the robot’s movements, enabling surgeons to perform intricate procedures with minimal invasiveness. As healthcare robotics continues to evolve, precision-engineered embedded systems will be integral to delivering safe and effective solutions in patient care.

Autonomous Drones and Delivery Robots

Drones and autonomous delivery robots have become essential in logistics, agriculture, and public safety. These robots rely on embedded hardware for navigation, obstacle detection, and data analysis. High-performance embedded systems with real-time processing capabilities enable drones to navigate complex terrains, avoid obstacles, and deliver packages with pinpoint accuracy. The efficiency and precision of embedded hardware are critical for ensuring these autonomous systems can perform reliably in outdoor and urban environments.

Consumer Robotics

From robotic vacuums to personal assistants, consumer robotics demand precision to deliver value to users. High-quality embedded hardware enables these devices to operate autonomously, respond to commands, and interact with their surroundings effectively. Precision embedded hardware also enhances the safety and reliability of consumer robots, ensuring they can perform daily tasks accurately and without fail.

The Future of Robotics Innovation Lies in Precision Embedded Hardware

As robotics continues to revolutionize industries worldwide, the demand for advanced, precision-engineered embedded hardware will only grow. Companies looking to lead in robotics must invest in high-quality embedded systems that support faster, more accurate, and intelligent robotic solutions. The role of embedded hardware in robotics is pivotal—it is the driving force behind innovative solutions that redefine what robots can achieve.

Embracing precision in embedded hardware enables companies to push the boundaries of robotics, fostering developments that make machines smarter, more adaptable, and more responsive to human needs. By focusing on excellence in embedded hardware design, innovators have the tools to create a new era of robotics, one where precision, reliability, and intelligence are standard.

Conclusion

The journey towards advanced robotics innovation begins with precision embedded hardware. By leveraging high-performance microcontrollers, efficient sensor integration, and emerging trends like AI and edge computing, embedded systems provide the foundation for tomorrow’s most groundbreaking robotics solutions. As industries continue to adopt and integrate robotics at an unprecedented rate, investing in quality embedded hardware is a step toward building robotic systems that redefine efficiency, accuracy, and reliability across countless applications.

With precision embedded hardware, the future of robotics is not only promising but incredibly dynamic, offering possibilities limited only by imagination. For companies committed to leading this revolution, embedding precision at the core of their hardware is essential to driving progress in the age of intelligent machines.

To Know More About embedded hardware