ASTM A335 P9 Seamless Pipe is a high-quality alloy steel pipe widely used in various industrial applications, including power plants, refineries, and petrochemical industries. Emirerri Steel is a trusted supplier of premium-grade A335 P9 pipes, ensuring superior durability, high performance, and excellent corrosion resistance.

What is ASTM A335 P9 Seamless Pipe?

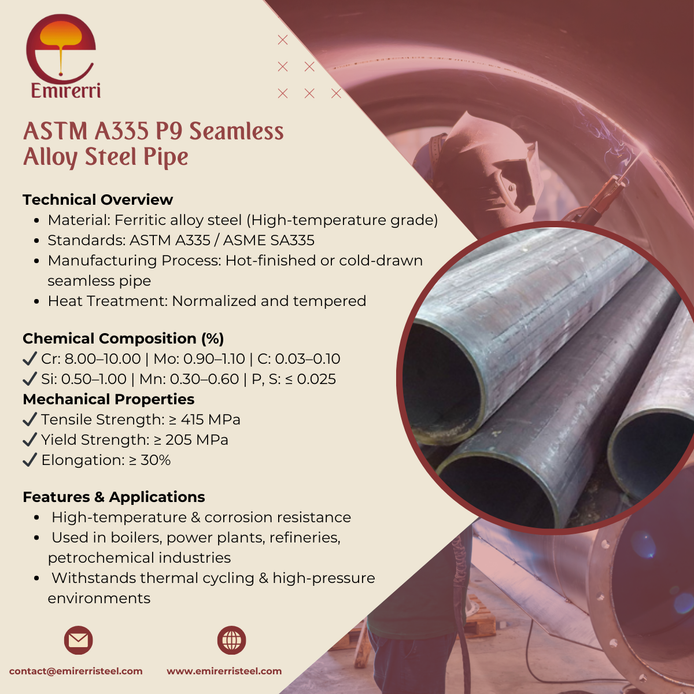

ASTM A335 P9 Seamless Alloy Steel Pipe designed for high-temperature applications. The seamless construction of these pipes enhances their strength, making them suitable for use in critical environments where high pressure and extreme heat are common. The presence of chromium and molybdenum in its composition improves its mechanical properties, including hardness, strength, and oxidation resistance.

Key Features of ASTM A335 P9 Alloy Steel Pipe

- Manufactured with high-strength alloy steel for durability

- Excellent resistance to high temperatures and pressure conditions

- Seamless construction for superior performance and reliability

- Ideal for high-temperature applications, including boilers, superheaters, and heat exchangers

- Good weldability and machinability for ease of installation

- Enhanced corrosion and oxidation resistance

P9 Material Composition and Chemical Properties

The chemical composition of ASTM A335 P9 pipes plays a crucial role in determining their strength, hardness, and resistance to oxidation. The P9 tube scale and A335 P9 chemical composition make it a highly sought-after material in industries requiring heat and pressure-resistant piping solutions.

Chemical Composition of A335 P9 Pipes

- Carbon (C): 0.15 max

- Manganese (Mn): 0.30-0.60

- Phosphorus (P): 0.025 max

- Sulfur (S): 0.025 max

- Silicon (Si): 0.50-1.00

- Chromium (Cr): 8.00-10.00

- Molybdenum (Mo): 0.90-1.10

The combination of chromium and molybdenum in P9 pipes enhances their mechanical and thermal properties, making them a preferred choice for critical applications.

Mechanical Properties of ASTM A335 P9 Pipes

- Tensile Strength: 415 MPa (min)

- Yield Strength: 205 MPa (min)

- Elongation: 30% (min)

- Hardness: 163 HB (max)

These properties ensure that A335 P9 pipes can withstand harsh operational conditions, making them ideal for various industries.

Applications of A335 P9 Pipes

ASTM A335 P9 seamless pipes are extensively used in industries that require high-temperature and high-pressure performance. Some of the key applications include:

- Power Generation Plants:

- Used in boilers and superheaters where high temperatures and pressures are common.

- Oil and Gas Refineries:

- Suitable for transporting fluids and gases under extreme conditions.

- Chemical Processing Industries:

- Utilized in heat exchangers and reactors.

- Petrochemical Industry:

- Used in high-temperature processing units and steam piping.

- Heat Exchanger and Boiler Manufacturing:

- Ideal for constructing heat exchanger tubes and boiler components.

- Aerospace Industry:

- Used in high-temperature applications requiring strength and oxidation resistance.

- Automotive Sector:

- Implemented in high-performance exhaust systems and turbocharger components.

Manufacturing Process of ASTM A335 P9 Seamless Pipes

The production of ASTM A335 P9 seamless pipes follows strict quality guidelines to ensure their superior performance. The process involves the following steps:

- Raw Material Selection: High-quality alloy steel is sourced to meet ASTM specifications.

- Heating and Piercing: The steel is heated to a high temperature and pierced to create a hollow tube.

- Elongation and Sizing: The tube is elongated and sized according to required dimensions.

- Heat Treatment: The pipes undergo annealing, normalizing, and quenching to enhance their mechanical properties.

- Cold Drawing and Finishing: Further processing ensures precise dimensions and smooth surface finishing.

- Testing and Inspection: Pipes are tested for strength, durability, and compliance with international standards.

Advantages of Alloy Steel P9 Pipes

- High-Temperature Resistance: Can withstand temperatures up to 600°C without losing structural integrity.

- Enhanced Durability and Strength: Provides long service life even in extreme environments.

- Reduced Risk of Scaling and Oxidation: Chromium and molybdenum content offer superior resistance to oxidation and corrosion.

- Superior Weldability and Machinability: Can be easily fabricated and welded for customized applications.

- Cost-Effective Performance: Offers a balance between cost and durability, making it a preferred choice for high-temperature services.

- Lightweight Yet Strong: Provides a high strength-to-weight ratio, making it ideal for applications requiring reduced weight without compromising durability.

Quality Standards and Testing Procedures

To ensure the highest quality, ASTM A335 P9 pipes undergo stringent testing procedures, including:

- Chemical Analysis: Ensuring precise alloy composition.

- Mechanical Testing: Evaluating tensile strength, yield strength, and elongation.

- Hardness Testing: Verifying hardness limits to prevent material failure.

- Hydrostatic Testing: Checking pressure resistance to avoid leakage.

- Non-Destructive Testing (NDT): Using ultrasonic, radiographic, and magnetic particle testing for defect detection.

- Dimensional Inspection: Ensuring adherence to ASTM dimensional standards.

Why Choose Emirerri Steel for ASTM A335 P9 Seamless Pipes?

Emirerri Steel is a renowned supplier of high-quality ASTM A335 Grade P9 Alloy Steel Seamless Pipes. Our commitment to quality and customer satisfaction ensures that you receive the best products for your industrial needs. Here’s why you should choose us:

- Premium-Grade Materials: We source high-quality raw materials to manufacture P9 pipes with excellent mechanical and chemical properties.

- Stringent Quality Control: Our products undergo rigorous testing to ensure compliance with ASTM and international standards.

- Competitive Pricing: We offer cost-effective solutions without compromising on quality.

- Timely Delivery: Our efficient supply chain ensures that your orders reach you on time.

- Expert Support: Our technical team provides assistance in selecting the right pipes for your application.

Conclusion

ASTM A335 P9 Seamless Pipes are an essential component in industries requiring high-temperature and high-pressure performance. With their exceptional chemical composition, mechanical properties, and durability, these pipes are widely used in power plants, refineries, and chemical industries. Emirerri Steel is your trusted partner in supplying top-quality alloy steel P9 pipes, ensuring reliability, performance, and cost-effectiveness. Contact us today to get the best deals on ASTM A335 P9 pipes tailored to your project requirements.