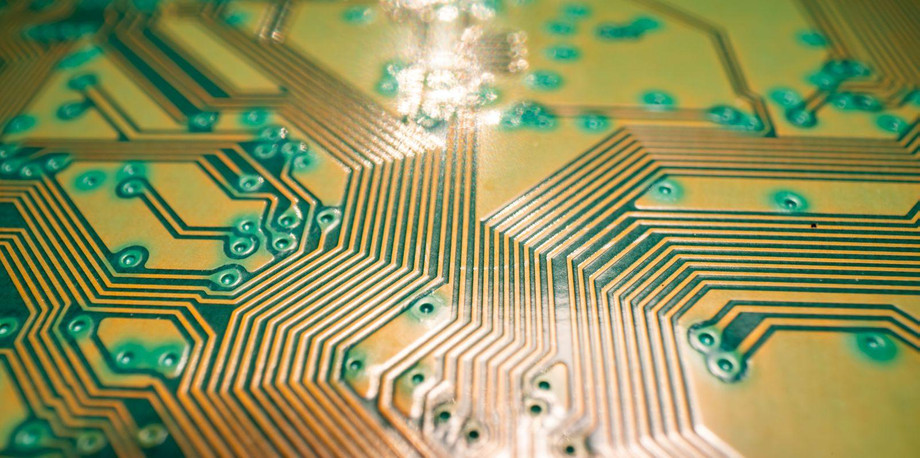

In the world of printed circuit board (PCB) design, every detail counts, and one such detail that plays a critical role is the concept of annular rings. These features are essential for ensuring reliable electrical connections and maintaining the integrity of the PCB during the manufacturing process. At Lion Circuits, we recognize the importance of understanding annular rings and their implications for effective PCB design.

What Are Annular Rings?

Annular rings refer to the circular band of copper that surrounds a plated-through hole on a PCB. Essentially, when a hole is drilled into the board and subsequently plated, the copper forms a ring around the hole. This ring is critical because it provides a conductive pathway between the pad and the plated hole, ensuring that electrical signals can pass through without interruption.

Importance of Annular Rings

-

Electrical Connectivity: The primary purpose of annular rings is to establish a reliable connection between the PCB’s pads and the through-hole components. If the annular ring is too small or improperly formed, it can lead to weak or intermittent connections, which can cause circuit failures.

-

Mechanical Strength: Annular rings contribute to the mechanical stability of the PCB. A well-formed ring ensures that components are securely anchored to the board, reducing the risk of damage due to thermal expansion or mechanical stress.

-

Manufacturing Tolerance: During the PCB fabrication process, various factors can affect the integrity of annular rings, such as drilling tolerances and plating processes. Understanding how to design effective annular rings can help mitigate issues during manufacturing, leading to higher yield rates.

Designing Effective Annular Rings

When designing PCBs, it’s crucial to consider the size and dimensions of the annular rings. Here are some guidelines to follow:

-

Minimum Ring Width: Aim for a minimum width of 0.2 mm for the annular ring to ensure a strong connection. However, this may vary based on specific manufacturing capabilities.

-

Drill Hole Size: The size of the drill hole impacts the annular ring width. When designing, make sure to account for the drill size and how it will affect the resulting annular ring.

-

Layer Count: In multilayer PCBs, consider how the annular rings will interface between layers. Proper alignment is crucial for maintaining electrical integrity across layers.

Conclusion

Understanding annular rings is fundamental for anyone involved in PCB design and manufacturing. These features play a vital role in ensuring electrical connectivity, mechanical strength, and overall reliability of the PCB. At Lion Circuits, we emphasize the importance of precise design practices, helping you create high-quality PCBs that meet your specifications. By paying close attention to details like annular rings, you can enhance the performance and longevity of your electronic devices. If you're looking for expert guidance on PCB design or manufacturing, reach out to us today!