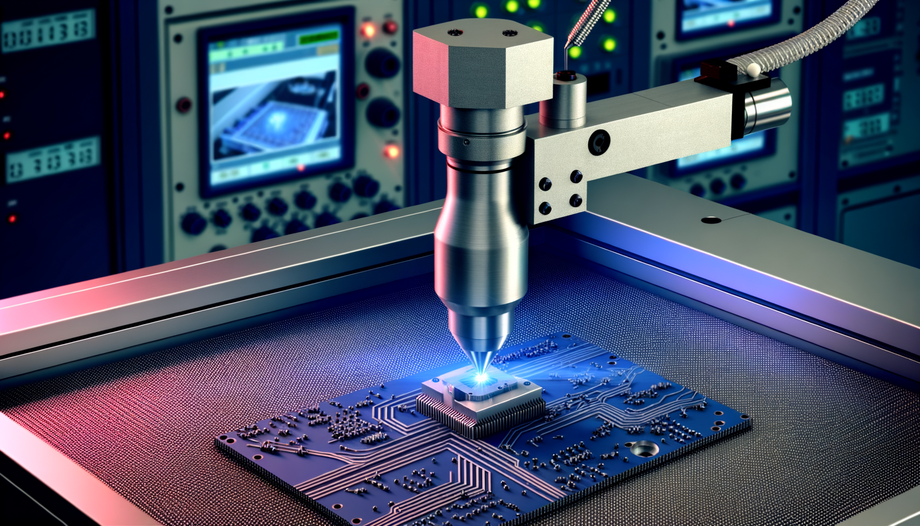

In an age where precision and efficiency define success in the electronics sector, innovations such as 2D laser micro trimming equipment are emerging as game-changers. As industries become increasingly reliant on microscale components, the demand for tools that deliver exactitude without compromising throughput is growing rapidly.

The Electronics Sector: A Quick Glance

Understanding the surge in demand for 2D laser micro trimming requires an acknowledgment of the broader context: the relentless evolution of the electronics industry. From smartphones to wearable devices, the push for smaller, faster, and more efficient components is constant. Consumer expectations drive manufacturers to seek methods that enhance product quality while maintaining cost-effective outputs, thus catalyzing the adoption of advanced laser technologies.

Why 2D Laser Micro Trimming?

It's not just about trimming; it's about precision, efficiency, and versatility:

- Ultra-Precision: The 2D laser micro trimming equipment allows for meticulous adjustment, ensuring that standards of excellence are not just met but exceeded.

- Material Versatility: These systems cater to a range of substrates, from semiconductor wafers to thick film resistors, making it indispensable across various applications.

- Cost-Efficiency: Minimizing material waste and reducing processing time ultimately translates to substantial cost savings.

- Quality Enhancement: Quantum improvement in output quality with reduced human intervention underscores the technology's allure.

- Customization Capabilities: The ability to provide custom solutions tailored to specific industry needs is a significant advantage.

Driving Innovation in Manufacturing

Manufacturers are leveraging 2D laser micro trimming technologies to redefine the nature of electronic production. As industries strive to integrate intricate design patterns, reduce device sizes, and boost energy efficiency, these laser systems offer a strategic advantage.

- Reducing Component Size: With escalating demands for miniaturization, electronic components need extreme precision level configurations only achievable through these advanced laser technologies. Whether it's intricate sensor circuits or resistive elements, each component intricately trimmed holds the promise of enhanced device functionality.

- Enabling High-Speed Production: The automation capacity of laser micro trimming equipment is empowering production lines with speed and reliability, minimizing downtimes and ensuring a faster time-to-market for electronic products.

- Enhancing Energy Efficiency: Precision trimming assists in optimizing performance parameters, thus significantly contributing to energy-efficient solutions—a key concern as industries pivot to sustainable practices.

Applications in Modern Electronics

Exploring where 2D laser micro trimming is making its mark uncovers its extensive reach:

- Semiconductor Industry: Adjustment and tuning of thin film resistors and capacitors with extraordinary precision.

- Consumer Electronics: Driving the innovation curve by enabling slimmer notebooks, robust smartphones, and efficient wearable gadgets.

- Automotive Sector: Contributing to the quest for lighter and smarter automotive electronics for advanced driving systems.

- Medical Devices: Ensuring minuscule and highly reliable components in critical medical instruments.

The Path Forward: Optimizing Excellence in Electronics

As technological advancement leads the charge toward more integrated and complex electronic systems, the role of high-precision trimming shifts from innovative to indispensable.

- Strategic Integration: Collaboration between laser technology providers and electronics manufacturers is vital. Such partnerships lead to the development of bespoke systems ushering in novel solutions, propelling innovation.

- Research & Development: Stakes at the research front are high, with continuous improvements in laser source quality, system compactness, and processing software.

- Training & Adaptability: As industries adopt these technologies, skilled personnel is essential to maximize their use. Training and adaptability become the cornerstones for achieving the full potential of these systems.

Final Thoughts

In a world where the line between science fiction and reality blurs by the day, tools like 2D laser micro trimming are not just enhancing electronics but are also redefining product evolution paradigms. With the integration of such innovative systems, ideas once deemed visionary become achievable realities, placing the electronics sector on the cusp of a spectacular transformation.

Explore Comprehensive Market Analysis of 2D Laser Micro Trimming Equipment Market

SOURCE -- @360iResearch