The automotive manufacturing industry is undergoing a significant transformation, driven by advancements in embedded software design. As vehicles become smarter and manufacturing processes more automated, embedded software plays a pivotal role in ensuring efficiency, safety, and innovation. This evolution is redefining the boundaries of what's possible in modern automotive production.

The Role of Embedded Software in Automotive Manufacturing

Embedded software serves as the silent powerhouse behind numerous automotive manufacturing operations. From robotics to assembly line management, it integrates various systems to function harmoniously. This seamless integration optimizes production cycles, minimizes errors, and enhances product quality—all essential for maintaining competitiveness in a dynamic market.

Consider the complexity of autonomous vehicle assembly. Each component requires precise calibration, and the process demands coordination between sensors, robotics, and human oversight. Embedded software ensures these systems operate in perfect synchronization, enabling faster production while adhering to strict quality standards.

Key Benefits of Embedded Software in Automotive Systems

-

Enhanced Efficiency

Embedded software optimizes the use of resources by automating repetitive tasks, reducing waste, and accelerating production timelines. Its ability to analyze data in real time enables predictive maintenance, minimizing downtime and maximizing throughput. -

Improved Precision and Quality Control

Automotive manufacturing requires meticulous precision. Embedded software facilitates accurate measurements and error detection, ensuring every product meets exacting standards. Advanced algorithms identify anomalies early in the process, reducing rework and associated costs. -

Scalability and Flexibility

Modern automotive systems must adapt to changing demands. Embedded software design provides the scalability needed to accommodate production variations, such as shifts between models or configurations. This flexibility is critical for manufacturers aiming to stay agile in a competitive market. -

Energy Efficiency and Sustainability

Embedded software plays a crucial role in optimizing energy usage across production lines. By intelligently managing power consumption, it helps manufacturers reduce their carbon footprint—a growing priority in today's environmentally conscious landscape.

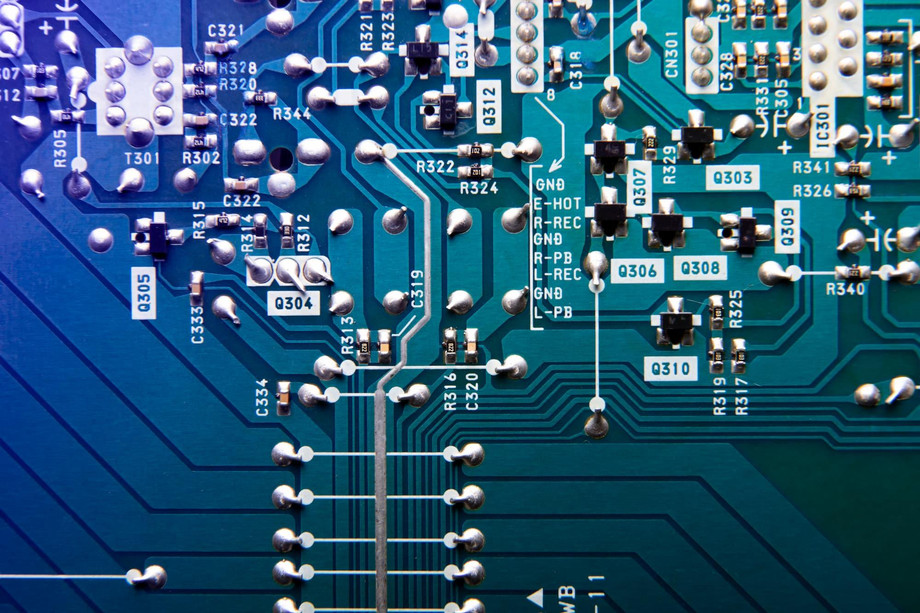

Core Components of Embedded Software Design

-

Real-Time Operating Systems (RTOS)

RTOS ensures the real-time execution of tasks, a necessity in high-speed automotive manufacturing environments. It prioritizes critical functions, maintaining system reliability under demanding conditions. -

Middleware and Communication Protocols

Middleware bridges the gap between hardware and application software, facilitating seamless communication. Protocols like CAN (Controller Area Network) and LIN (Local Interconnect Network) ensure efficient data exchange across manufacturing systems. -

Security Frameworks

With the rise of connected systems, cybersecurity is paramount. Embedded software integrates robust encryption and intrusion detection mechanisms to safeguard critical manufacturing processes against potential threats. -

Integration with IoT and AI

Embedded systems increasingly leverage IoT devices and AI algorithms for predictive analytics, machine learning, and enhanced decision-making. These technologies empower manufacturers to anticipate issues, optimize workflows, and achieve superior outcomes.

Applications in Automotive Manufacturing

-

Robotics and Automation

Embedded software powers robotic arms and automated systems that handle complex assembly tasks with precision. These systems are programmed to adapt to changes, such as new vehicle designs or varying production volumes. -

Quality Assurance Systems

Automated inspection systems, driven by embedded software, analyze components for defects in real time. High-resolution imaging and AI-based analysis ensure that only top-quality products move forward in the production process. -

Supply Chain Management

Embedded systems streamline inventory tracking and supply chain logistics, ensuring materials arrive just in time. This minimizes delays and reduces storage costs, enhancing overall efficiency. -

Human-Machine Interfaces (HMI)

Intuitive HMIs allow operators to interact with manufacturing systems effectively. Embedded software enables user-friendly interfaces that display critical data, guide workflows, and facilitate troubleshooting.

Challenges in Embedded Software Design for Automotive Manufacturing

Despite its advantages, embedded software design faces unique challenges:

- Complexity Management: Automotive systems are intricate, requiring software that integrates diverse components without compromising performance.

- Real-Time Processing Demands: Manufacturing operations rely on immediate responses; any lag could disrupt production and impact quality.

- Regulatory Compliance: Adhering to industry standards and safety regulations adds layers of complexity to software design.

- Cybersecurity Risks: Connected systems are vulnerable to cyberattacks, necessitating advanced security protocols and constant monitoring.

Future Trends Shaping Embedded Software in Automotive Manufacturing

-

Edge Computing

Edge computing reduces latency by processing data locally rather than relying on centralized servers. This innovation is particularly beneficial for time-sensitive manufacturing operations. -

Digital Twin Technology

Embedded software facilitates digital twin models, which replicate physical manufacturing systems in a virtual environment. These models enable simulation, testing, and optimization without disrupting actual production. -

AI-Powered Predictive Maintenance

AI algorithms integrated with embedded systems predict equipment failures before they occur. This reduces downtime, extends machinery lifespan, and ensures uninterrupted production. -

Sustainability Integration

As sustainability becomes a priority, embedded software is being designed to optimize energy use, reduce waste, and monitor environmental impact throughout manufacturing processes.

Why Embedded Software Is the Future of Automotive Manufacturing

The automotive manufacturing landscape is evolving at an unprecedented pace, and embedded software design is at the forefront of this transformation. Its ability to enhance efficiency, ensure precision, and integrate cutting-edge technologies makes it an indispensable tool for modern production systems.

Manufacturers that invest in robust embedded software solutions not only gain a competitive edge but also position themselves as pioneers in a rapidly changing industry. From streamlining operations to embracing sustainability, embedded software is the key to driving innovation and excellence in automotive manufacturing.

Final Thoughts

The shift toward intelligent, automated, and sustainable manufacturing underscores the importance of embedded software in shaping the future of the automotive industry. By prioritizing advanced design principles and embracing emerging technologies, businesses can unlock new levels of efficiency and innovation.

For organizations aiming to lead in this space, now is the time to explore and invest in cutting-edge embedded software solutions tailored to the demands of modern automotive manufacturing.

To Know More About embedded software design