In today’s industrial landscape, hydraulic hose pipes play a vital role in powering and operating complex machinery. These specialized hoses facilitate the smooth transfer of hydraulic fluid between various components, making them essential for industries such as construction, agriculture, manufacturing, and more. In this guide, we’ll cover everything you need to know about hydraulic hose pipes, including their types, benefits, and tips for choosing the right one for your application.

What is a Hydraulic Hose Pipe?

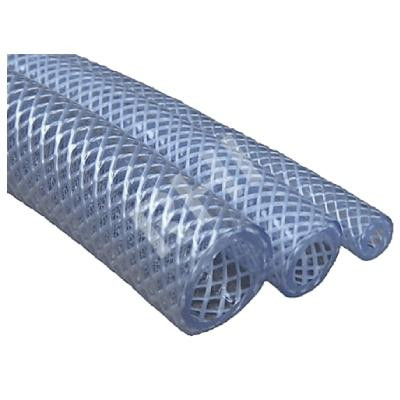

A hydraulic hose pipe is a flexible, reinforced tube designed specifically to carry hydraulic fluid at high pressures within a hydraulic system. Unlike standard hoses, hydraulic hoses are built to handle intense pressures and extreme operating conditions. They’re crucial in transferring power between hydraulic components like pumps, valves, and actuators, enabling movement and operation in a wide range of machinery and equipment.

Types of Hydraulic Hose Pipes

Hydraulic hose pipes are available in several types, each suited to specific applications and pressure requirements. Here are the most common types:

- Braided Hydraulic Hose

Braided hydraulic hoses are ideal for moderate-pressure applications. They are typically reinforced with textile or steel braiding, giving them durability while maintaining flexibility. - Spiral Hydraulic Hose

Spiral hydraulic hoses are designed for high-pressure and heavy-duty applications. They have multiple layers of spiral wire reinforcement, making them capable of withstanding higher pressures compared to braided hoses. - Thermoplastic Hydraulic Hose

Thermoplastic hoses are used in applications where chemical resistance and abrasion protection are essential. These hoses are lightweight and flexible, suitable for various mobile equipment. - Teflon Hydraulic Hose

Known for their superior chemical resistance and ability to handle high temperatures, Teflon hoses are used in environments that require the transfer of aggressive fluids or exposure to extreme temperatures.

Key Applications of Hydraulic Hose Pipes

Hydraulic hose pipes are versatile and widely used across numerous industries, including:

- Construction: They power heavy equipment like excavators, loaders, and bulldozers, ensuring smooth operation even under demanding conditions.

- Agriculture: Hydraulic hoses are integral to tractors, harvesters, and other machinery, making it easier for farmers to perform tasks efficiently.

- Manufacturing: Hydraulic systems in factories rely on hoses to facilitate fluid transfer in assembly lines, molding equipment, and material-handling machines.

- Automotive: From hydraulic brakes to power steering, the automotive industry uses hydraulic hoses in various applications for precise control and operation.

Benefits of Hydraulic Hose Pipes

Using high-quality hydraulic hose pipes brings numerous advantages:

- Efficient Fluid Transfer: Hydraulic hoses ensure fluid is transferred at the correct pressure, essential for power transmission and operational efficiency.

- Flexibility and Versatility: These hoses are highly flexible, allowing for easy installation in compact spaces and across varied machinery types.

- Durability and Safety: Made with multiple layers of reinforcement, hydraulic hoses can withstand extreme conditions, providing long-lasting, reliable performance.

- Reduced Maintenance Costs: High-quality hoses lower the risk of leaks and breakdowns, reducing downtime and saving maintenance costs over time.

- Enhanced Productivity: With a hydraulic hose that meets application requirements, businesses can enhance productivity through smoother and safer machine operation.

How to Choose the Right Hydraulic Hose Pipe

Selecting the right hydraulic hose pipe is critical to the efficiency and safety of your hydraulic system. Here are some tips to help you make the right choice:

- Understand the Pressure Requirements: Each hose type has a specific pressure rating. Assess your system’s maximum pressure needs and choose a hose that matches or exceeds this requirement.

- Consider the Fluid Compatibility: Hydraulic hoses are designed for various fluids. Make sure the hose material is compatible with the type of fluid used in your system to avoid chemical breakdown.

- Account for Temperature Range: Some hydraulic hoses are better suited for extreme temperatures. If your application involves high or low temperatures, opt for a hose with appropriate thermal resistance.

- Choose the Right Size: Hoses come in different diameters, so choose a size that ensures optimal flow rate for your application. Oversized or undersized hoses can cause system inefficiencies.

- Inspect Reinforcement Layers: The number of reinforcement layers impacts a hose’s durability. For heavy-duty applications, spiral hoses with multiple reinforcement layers are often the best choice.

Maintenance Tips for Hydraulic Hose Pipes

Proper maintenance is key to extending the life of your hydraulic hose pipe and ensuring reliable performance:

- Regular Inspections: Periodically inspect the hose for signs of wear, cracks, or leaks. Address any visible damage immediately to prevent accidents.

- Store Correctly: Avoid bending or kinking hoses, and store them in a cool, dry place away from direct sunlight and chemicals.

- Avoid Excessive Pressure: Use hoses within their pressure rating to prevent early wear and tear.

- Clean Routinely: Regularly clean hoses to avoid build-up of dirt or residues, which can lead to blockages or degradation.

Why Choose Rubber Hose India LLP for Hydraulic Hose Pipes?

Rubber Hose India LLP is a trusted provider of hydraulic hose pipes in India, offering high-quality products designed to meet the rigorous demands of industrial applications. Established in 1993, Rubber Hose India LLP has a reputation for quality and customer satisfaction, providing hoses that are compliant with top industry standards. Their offerings include a range of hydraulic hose pipes, from braided to spiral hoses, as well as custom solutions for specific industrial needs.

With in-stock availability of various hose sizes and fittings, Rubber Hose India LLP ensures timely delivery, quality testing, and support from experienced technical staff. Their state-of-the-art manufacturing facility allows for customization and batch testing to ensure each hose assembly is built to last and meets your requirements.

Final Thoughts

Hydraulic hose pipes are integral to maintaining the performance and safety of hydraulic systems across industries. Whether you’re involved in construction, agriculture, manufacturing, or automotive, choosing the right hydraulic hose is essential for maximizing machine efficiency and minimizing downtime.

By understanding the different types of hydraulic hoses, their applications, and how to select the right one, you can ensure your equipment operates smoothly and safely. For high-quality and reliable hydraulic hose solutions, consider partnering with a trusted supplier like Rubber Hose India LLP, where quality and customer satisfaction are the priorities.

.

Visit- https://rubberhoseindia.com/