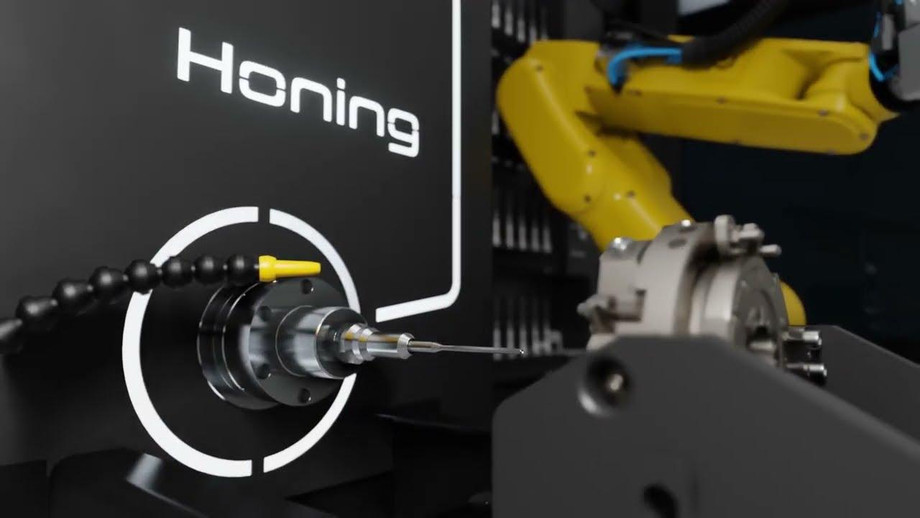

In order to repair errors in metal, honing machines use harsh tools and perishable abrasive stones.

- Measurement

- Form

- Finished surface

- Tolerances for bore position

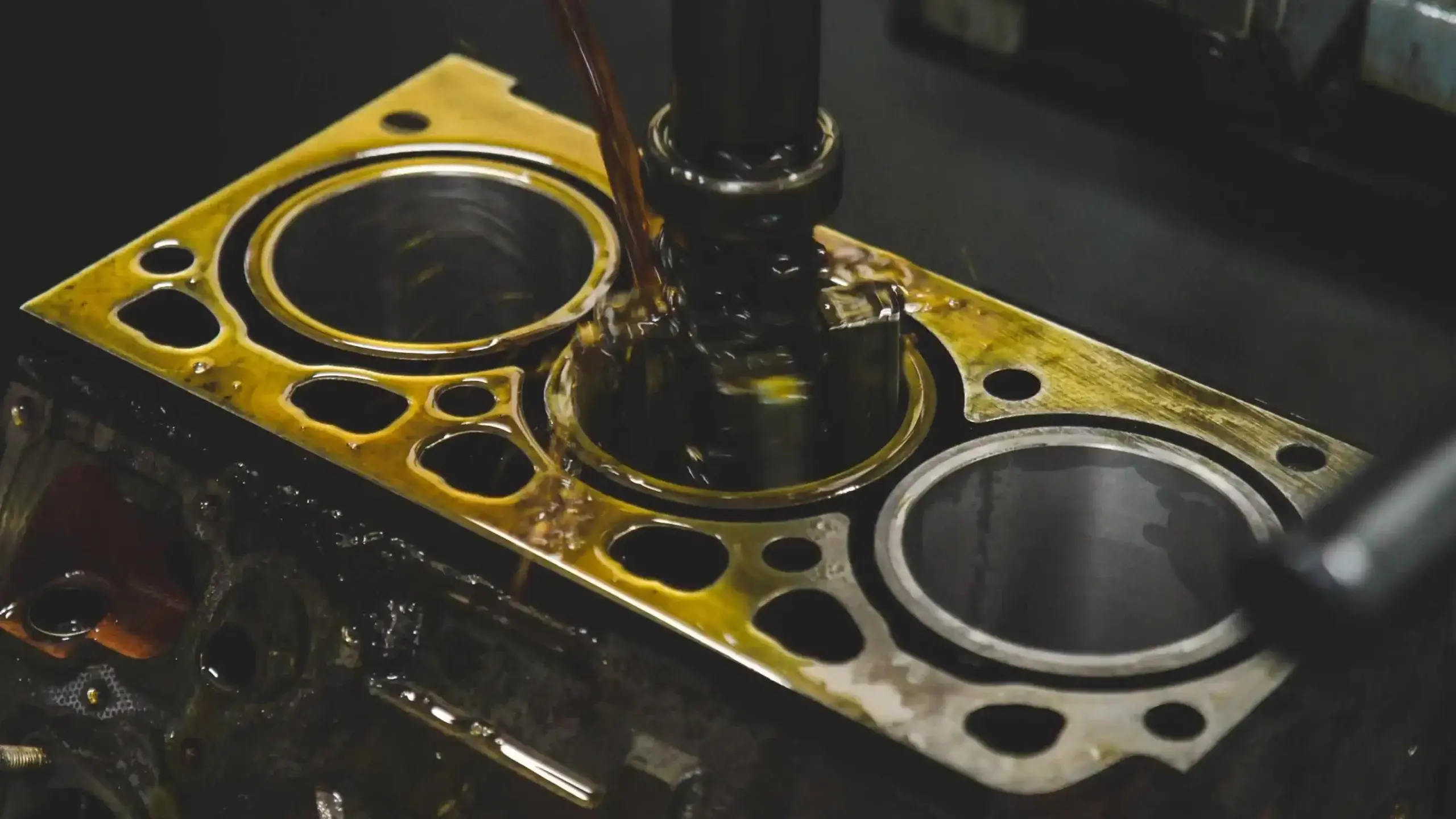

To achieve the highest standards in bore geometry, size control, final surface finish, and surface structuring, the hone process was created. The inside of tubing or cylinder bores receives the final sizing and the desired finish pattern thanks to the honing procedure. By pressing abrasive stones of the right grit and grade up against the work surface, finishing is achieved. Under regulated pressure, the stones are reciprocated and turned in the section containing hone abrasive. The part surface that is being honed takes on a crosshatch pattern when rotation and reciprocation are combined.

Why Honing?

Efficient machining technique for:

- Taking Stock Out

- Producing precise

- Tolerance for boredom

- Polishing of bores

- Finishing bores made of nearly any material, including ceramics, CGI, sprayed coatings, etc.

Define The Honing (Process):

In tubing or cylinder bores, the honing process produces the final size and the required finish pattern. Abrasive stones of the right grit and grade are expanded against the work surface to achieve finishing. In the section with hone abrasive, the stones are reciprocated and rotated under regulated pressure. A cross-hatch pattern is created on the surface of the item being sharpened by combining rotation and reciprocation.

Three Operations Are Performed by Honing Machines:

- In order to get to base metal, ruptured metal must first be removed using the stock removal procedure.

- The optimal surface for encouraging ideal lubrication conditions is then produced by creating a finish pattern.

- The third benefit of honing is that it guarantees the cylinder surface's exact size, roundness, and straightness.

What is an Honing Machine with Single Pass?

A boring bar-style honing tool with diamond abrasive is used for one pass honing. When using this kind of honing tool, the part is produced with a straight, round, and un-tapered bore after just one tool pass. Engine crank and cam bore honing is a perfect application for single pass honing. There is no crosshatch pattern in the final product because size is attained in a single pass. Similar to ordinary tooling, the adjustable single pass tool stretches the hone stones in a cone shape. But unlike traditional honing, the stones are not pushed and pulled back. Only the stone's size is achieved by expansion. The hone tool is longer than typical tooling, and the extremely abrasive layer runs the entire length of the tool. This is the other distinction. The single pass honing has a final size section of 2.5 inches and taper for around seven inches. The machine must be halted in order to change the single pass tool because it lacks in-process hone expansion.

When Is Single-Pass Tooling the Best Option?

Bore finishing, another name for single-pass honing machines, is used in many applications where honed cavities are required for unique purposes.

- Honing machine with small diameter (usually between 2)

- Large-scale production

- Lower cost per unit

- Less time lost when switching out tools

- Reliability in measuring dimensional tolerances including surface finish, roundness, and bore size.

- For the Single-Pass procedure, only super-abrasive materials (Diamond and CBN) are utilized.

- Chips from the honing region must be continuously removed, which requires a high coolant rate or volume.

- Single Pass honing can be done with either oil-based or water-base coolant, however oil is the more popular option.

There are restrictions on the kinds and amounts of material that can be removed with the single pass honing procedure. More specifically, the amount and size of chips removed should not exceed the space available between the super-abrasive grits on the tool sleeve. Therefore, honing processes that yield a small quantity of chips, like interrupted or short length bores, are best suited for the Single Pass honing method. It works best (though not exclusively) for fine-tuning cast iron and metal powders.

Single pass honing is not recommended for applications needing large amounts of material to be eliminated, a lengthy length of material to be sharpened, or small quantities of material. Conventional Honing might be a better option for them. For applications of this kind, traditional honing is also frequently able to offer good dimensional geometry.

Why Honing Machines / Systems?

For all of your honing needs, Abhi's Honing Machines & Finishing Systems provides a full range of products. For high volume manufacturing applications, we can provide fully integrated systems and machines; for low volume job shop applications, we can provide equipment. For already-existing equipment, we can provide rebuild and upgrade services. Together with a wide range of accessories and consumables, thorough training, and repair services, we offer our clients fully engineered, tailored solutions.

The purpose of Abhi's honing machine's design and engineering is to increase worker productivity. With the most recent technology, these kinds of vertical honing machines may be quickly switched between medium and high volume productions without the need for manual controls.

Why Buy Honing Machines / Systems?

Abhi's Honing Machine features a compact and rigid machine design with tool expansion up to 0.1μm per pulse. It offers high productivity with minimal changeover time, enabling achievement of 1 micron bore accuracy and high surface finish. The machine ensures required roundness and cylindricity, equipped with high precision ground ball screws and LM guideways. It is suitable for automotive components such as fuel injectors, engine blocks, and gears. The spindle speed ranges from 5 to 2000 RPM, while the stroker speed reaches up to 30000 mm/min. The spindle motor is servo-controlled, and the machine includes centralized auto lubrication system for efficient operation.