The automotive industry is currently navigating an era of transformative change, driven by the need for innovation and sustainability. Manufacturers are continuously seeking cutting-edge solutions that boost vehicle performance, prioritize safety, and cater to consumers' increasing demand for fuel efficiency. Among these pioneering technologies, flux cored welding wire has emerged as a star player for its role in crafting durable and lightweight vehicle components. Let's delve into how this technology is shaping the future of automobiles.

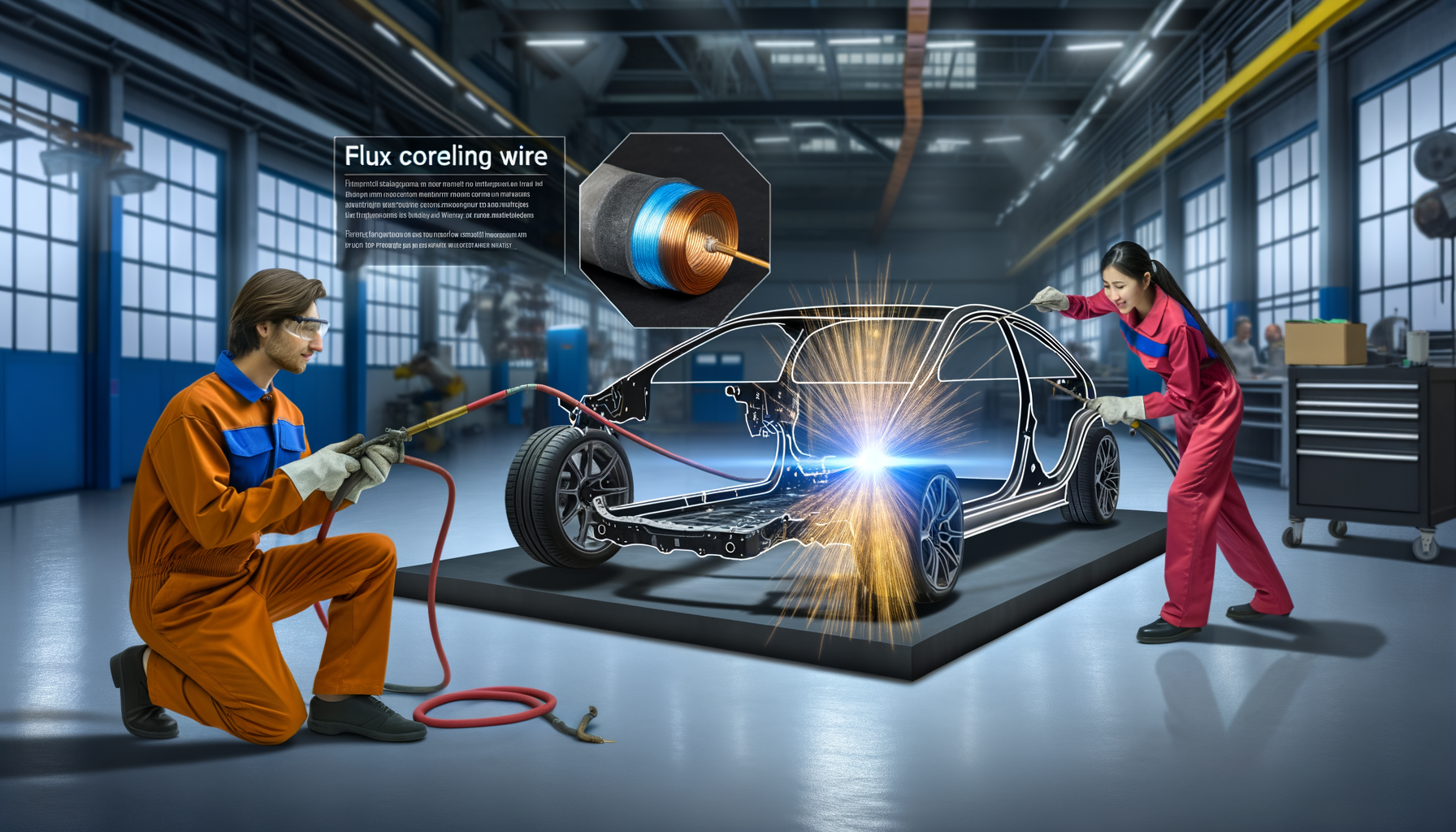

A Spotlight on Flux Cored Welding Wire

Flux cored welding wire is a type of tubular wire filled with flux material that offers unique benefits during the welding process. Known for its superior weld quality and versatility, it has traditionally been employed in sectors such as shipbuilding, construction, and heavy machinery. However, its increasing adoption in the automotive industry is noteworthy, with its promise to enhance vehicle performance and component longevity.

Why the Automotive Sector is Turning to Flux Cored Welding Wire

- Lightweighting the Vehicles: As automakers strive to reduce the weight of vehicles to improve fuel efficiency and decrease emissions, the materials used become crucial. The flux cored welding technique allows for the crafting of thinner and lighter components without compromising strength or performance, making it a perfect fit for modern manufacturing needs.

- Strengthening Durability: Ensuring that vehicles withstand diverse environmental conditions is paramount for manufacturers. The use of flux cored welding wire enhances the durability of auto components, ensuring resistance to corrosion and wear over time, ultimately providing longer-lasting and safer vehicles for consumers.

- Efficiency in Production: The automotive industry values efficiency, and the flux cored welding process is known for its speed and precision. When implemented during manufacturing, it reduces the need for post-weld clean-up and rework, leading to lower production costs and shorter lead times.

Understanding the Technology Flux cored welding wires are available in two types – self-shielded and gas-shielded:

- Self-Shielded: Ideal for outdoor applications where wind might compromise the protective gas envelope.

- Gas-Shielded: Preferred in controlled environments where there's minimal interference, leading to a higher quality finish.

Both types bring unique properties that cater to varying requirements within the automotive sector.

Applications in the Automotive Industry

- Chassis Manufacturing: The chassis forms the vehicle's backbone, and the requirement for it to handle dynamic stress while keeping weight minimal is especially crucial. The use of flux cored wires ensures robust joints, maintaining structural integrity without piling on extra weight.

- Exhaust Systems: Exhaust systems require exceptional heat tolerance and resistance to high-velocity gases. Flux cored welding wires provide the necessary durability while facilitating innovative designs catered towards efficient exhaust flow.

- Suspensions: Automotive suspensions face rigorous demands, requiring welding protocols that ensure resilience. The expertise of flux cored welding meets these requirements perfectly, offering strong, lasting bonds for various materials.

The Road Ahead

As automakers continuously innovate to meet stringent environmental regulations and heightened consumer expectations, the role of materials in vehicle manufacturing simply cannot be overstressed. Flux cored welding wire is not just another tool – it is shaping the future of the automotive industry, offering opportunities for manufacturers to achieve their goals of creating lightweight, durable, and fuel-efficient vehicles.

Conclusion

In summary, flux cored welding wire represents an exciting frontier for the automotive industry. Its rising popularity is testimony to the engineering marvels it promises. As we continue to seek out ways to refine and innovate within the automobile sector, embracing such advanced technologies will undoubtedly steer us toward more sustainable, efficient, and robust vehicles. For professionals and enthusiasts alike, keeping an eye on these developments is essential as they hold the key to the future of automotive manufacturing.

Explore Comprehensive Market Analysis of Flux Cored Welding Wire Market

SOURCE-- @360iResearch