Exploring the World of CNC Plasma: Revolutionizing Metal Fabrication

In the realm of metal fabrication, precision and efficiency are paramount. CNC plasma technology has emerged as a game-changer, offering unparalleled accuracy and speed in metal cutting processes. This blog delves into the intricacies of CNC plasma, exploring its functionality, benefits, applications, and the role of industry leaders like CompleteMachineTools in advancing this technology.

What is CNC Plasma?

CNC (Computer Numerical Control) plasma cutting is a process that employs a high-velocity jet of ionized gas, known as plasma, to cut through electrically conductive materials such as steel, aluminum, brass, and copper. The plasma torch is guided by a computer, allowing for precise and repeatable cuts.

The Mechanics of CNC Plasma Cutting

CNC plasma cutting machines consist of several key components, including the plasma torch, power supply, control console, and cutting table. The process begins with the generation of a plasma arc by passing a gas like oxygen or nitrogen through a nozzle. When this gas is ionized by an electrical arc, it forms a plasma jet capable of reaching temperatures exceeding 20,000 degrees Celsius, effectively melting and cutting through metal.

Benefits of CNC Plasma Cutting

Precision and Accuracy

One of the primary advantages of CNC plasma cutting is its precision. The computerized control allows for intricate and complex designs with minimal error. This precision reduces material wastage and enhances overall production efficiency.

Speed and Efficiency

CNC plasma cutters are renowned for their speed. They can cut through thick metal plates swiftly, increasing productivity while maintaining high-quality results. This speed is crucial for meeting the demands of modern manufacturing, where time-to-market is a critical factor.

Versatility

CNC plasma cutters offer versatility in terms of the materials they can handle. From thin sheets to thick metal plates, this technology can accommodate various thicknesses and types of metals, making it an ideal choice for diverse applications.

Cost-Effectiveness

With reduced material wastage, faster processing times, and minimal human intervention, CNC plasma cutting is a cost-effective solution for metal fabrication. Manufacturers can achieve higher output with lower operational costs.

Applications of CNC Plasma

Industrial Manufacturing

CNC plasma technology finds extensive use in industrial manufacturing, where precision and efficiency are crucial. Industries such as automotive, aerospace, and shipbuilding rely on CNC plasma cutters for fabricating components with tight tolerances and intricate designs.

Art and Sculpture

Beyond industrial applications, CNC plasma cutters have found their place in the world of art and sculpture. Artists use this technology to create detailed and elaborate designs in metal, bringing their creative visions to life with precision.

Construction and Architecture

In construction and architecture, CNC plasma cutting is used for creating structural components, decorative elements, and intricate metalwork. The ability to produce complex shapes and patterns enhances aesthetic appeal and functionality.

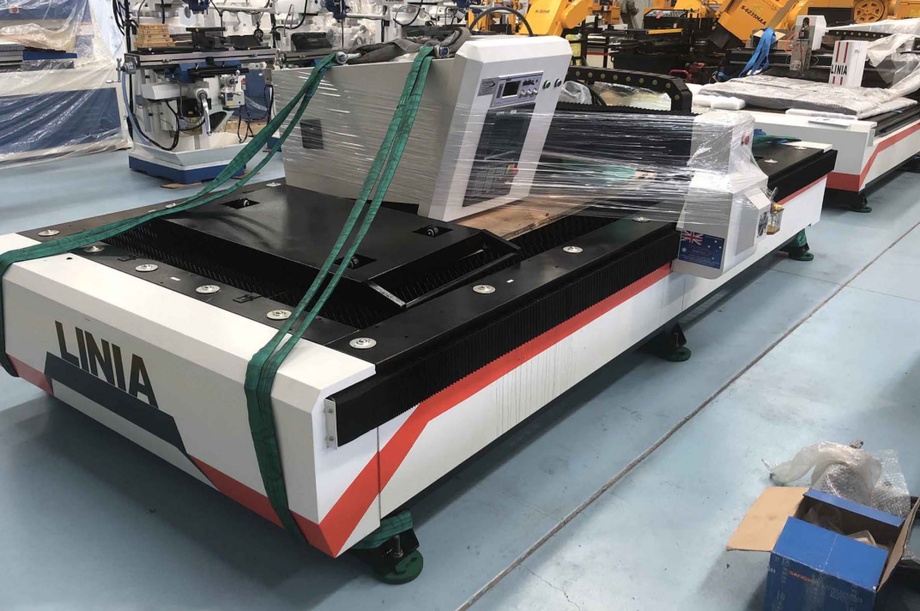

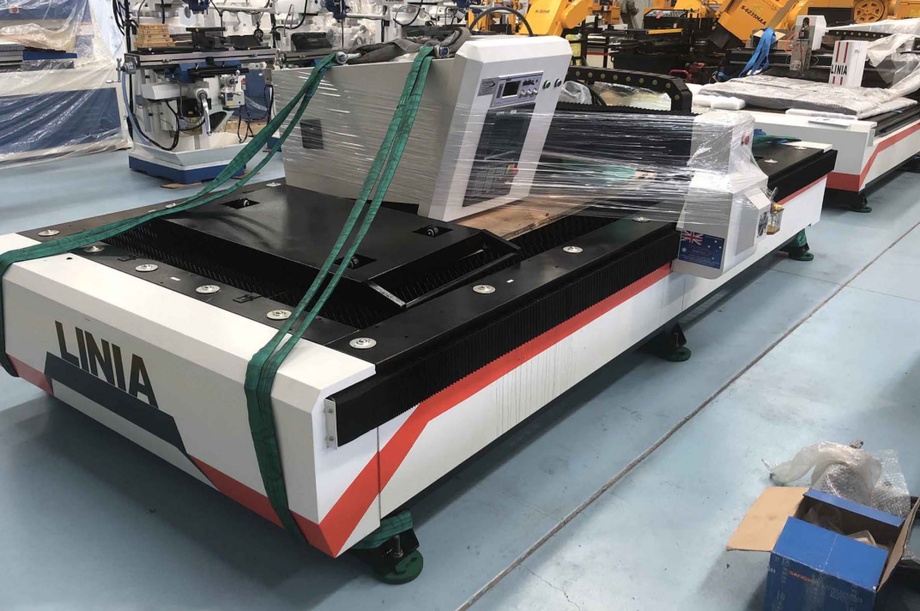

The Role of CompleteMachineTools in Advancing CNC Plasma Technology

CompleteMachineTools is a leading provider of CNC plasma solutions, offering cutting-edge technology that caters to diverse industrial needs. Their commitment to innovation and quality has positioned them as a trusted partner in the metal fabrication industry.CompleteMachineTools specializes in high-performance CNC plasma machines that deliver precision and efficiency. By integrating advanced features such as automated controls, intuitive interfaces, and robust construction, they ensure that their customers achieve optimal results in their metal cutting processes.

Conclusion

CNC plasma technology has revolutionized metal fabrication, offering precision, speed, and versatility. CompleteMachineTools, a leader in this field, provides top-of-the-line CNC plasma solutions that empower manufacturers to achieve superior results. As CNC plasma continues to evolve, it promises to play a pivotal role in shaping the future of metalworking.