In today's fast-paced industrial landscape, regulatory compliance is far more than a mere checkbox activity. With increasing environmental scrutiny and stringent industrial regulations, businesses are on the brink of reevaluating their filtration strategies to balance operations efficiently and sustainably. This regulatory heatwave has catalyzed a rising tide for innovative solutions, particularly in the realm of filtration systems. Among the unsung heroes of this transformation are homopolymer acrylic needle felt filter bags—an industrial marvel charting the course of cleaner operations.

The Regulatory Pillow of Demand

Environmental and industrial regulations are pivotal in dictating industry trends. From air quality standards to emission restrictions, these regulations are constantly evolving, tightening the screws on pollution control measures and forced industry participants to explore ingenious solutions that ensure compliance without compromising on productivity.

- Air Quality and Emission Norms: Emerging laws on surface emissions and air quality are pushing industries to improve their filtration frameworks. Whether it's the EU's Industrial Emissions Directive or the United States' Clean Air Act, each comes with its distinct set of challenges and expectations to be met.

- Sustainability Imperatives: Companies are now recognizing the fiscal and reputational dividends of sustainable operations, driving them to align closely with regulations that prioritize eco-friendly practices.

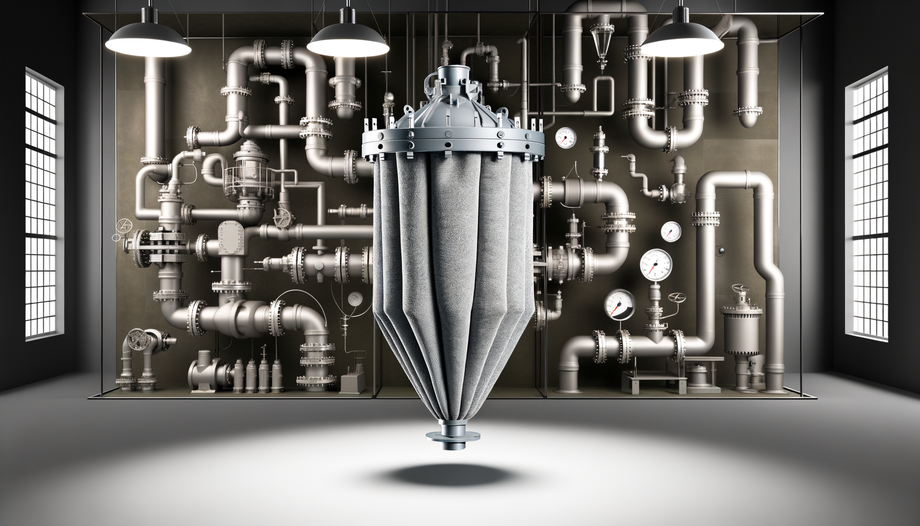

Unpacking Homopolymer Acrylic Needle Felt Filter Bags

So where do homopolymer acrylic needle felt filter bags fit into this meticulous tapestry of industrial compliance? Thanks to their unique properties and wide range of applications, these filter bags step up as a compelling choice.

1. Temperature and Chemical Resilience

Homopolymer acrylic fibers are renowned for their ability to withstand elevated temperatures and resist various chemicals. This makes them ideally suited for industries dealing with high-temperature processes and items prone to chemical attacks, such as cement, chemicals, and pharmaceuticals.

2. Remarkable Filtration Efficiency

The homopolymer acrylic needle felt ensures a robust filtration process, capturing finer particulates that slip through traditional filters. Their finer pore size distribution equips industries to meet and exceed emission regulations, promising cleaner air and water outputs.

3. Cost-Effectiveness and Longevity

While regulatory compliance often incurs additional costs, these filter bags present a cost-effective solution for their endurance and high retention capabilities. Workers find their longevity significantly minimizes changeover frequency and downtime, curbing operation costs.

Real-World Impact & Case Studies

Understanding the profound impact of tardy compliance with regulations, companies across industries have adopted these filtration marvels with notable success:

- Cement Industry: Facing potential fines for exceeding allowed particulate emissions, a leading cement manufacturer turned to homopolymer acrylic filters. The results? A 30% reduction in waste and exceeding air quality regulations within months.

- Pharmaceutical Sector: Rigorous cleanliness requirements saw pharmaceutical companies switching to these resilient filters, resulting in sterile environments and improved product consistency.

Future of Industrial Filtration

The quest for cleaner operations is not fleeting; it is a movement, a clarion call for change. As industries grow, the focus will pivot even more sharply towards efficiency and sustainability.

- Innovations on the Horizon: Expect continuous advancements, with emerging variants of homopolymer filters promising enhanced performance, broader range tolerance, and self-sterilization capabilities.

- Global Compliance as a Benchmark: International cooperation will push industrial entities to adopt a global standard, with massive implications for filtration solutions tailored to universal norms.

- Eco-conscious Industry Players: More companies will make environmentally responsible investments, seeing these not just as an obligation but an integral part of their ethical code.

Conclusion

As regulations continue to evolve, industries are facing an irreversible shift towards advanced filtration solutions to stay ahead of the curve. Embracing homopolymer acrylic needle felt filter bags not only ensures compliance but paves a transformative path towards sustainable growth. In an era where regulation drives innovation, these filters promise to be at the frontline of facilitating cleaner, responsible, and efficient industrial processes.

Explore Comprehensive Market Analysis of Homopolymer Acrylic Needle Felt Filter Bags Market

SOURCE -- @360iResearch