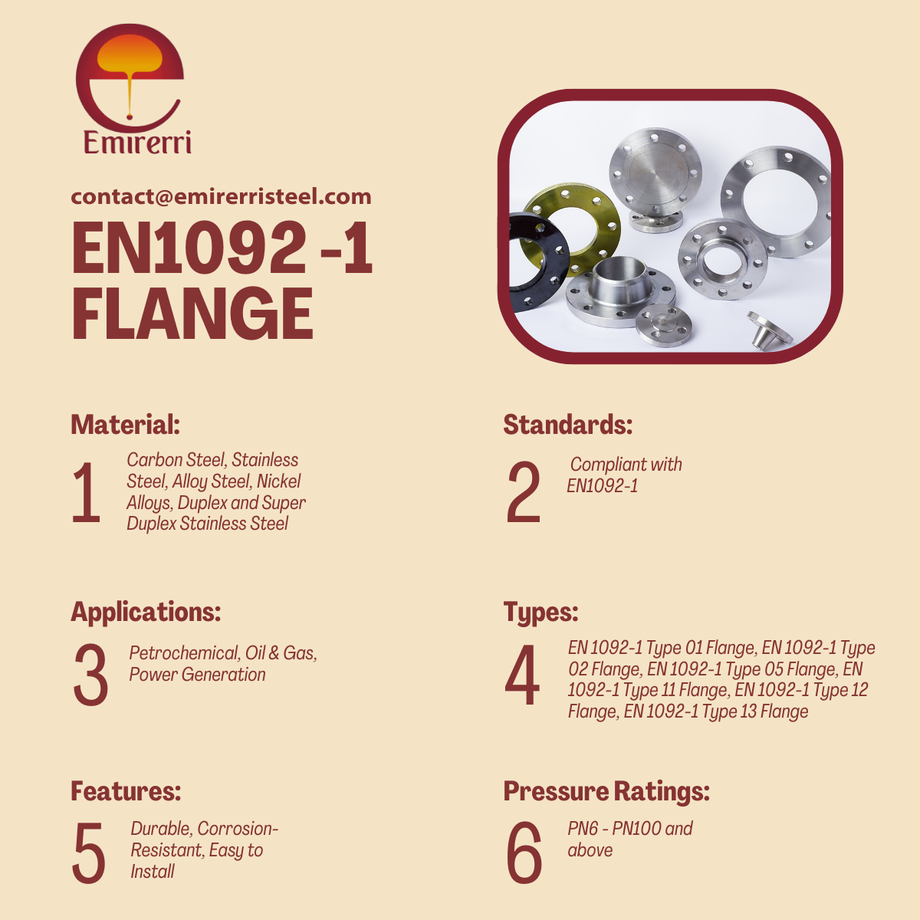

At Emirerri Steel, we pride ourselves on manufacturing premium-quality EN1092-1 Flanges that cater to diverse industrial applications. These flanges are engineered to meet stringent international standards, ensuring reliability, durability, and precision in every product. Below, we delve into the features, types, specifications, and certifications of EN1092-1 Flanges, ensuring you find the ideal solution for your project.

What is EN1092-1 Flange?

The EN1092-1 standard outlines the dimensional and functional requirements for flanges in piping systems. It is widely adopted in European and global industries due to its precision and compatibility with various applications, including high-pressure systems.

Key Features of EN1092-1 Flange

- Versatility: Suitable for a variety of pressure ratings and applications.

- High-Grade Materials: Manufactured using Stainless Steel, Carbon Steel, Alloy Steel, and Duplex/Super Duplex Steel.

- Corrosion Resistance: Designed to withstand harsh environments and aggressive chemicals.

- Robust Performance: Handles high-pressure and high-temperature conditions effectively.

- Dimensional Precision: Ensures leak-proof connections and smooth assembly.

Specifications of EN1092-1 Flanges

- Standards: EN1092-1:2018 (Latest Edition).

- Pressure Ratings: PN 6, PN 10, PN 16, PN 25, PN 40, PN 63, and PN 100.

- Sizes: DN 10 to DN 2000 and custom sizes as per client requirements.

- Materials:

- Stainless Steel: Grades 304, 304L, 316, 316L, 321, etc.

- Carbon Steel: Grades ASTM A105, A350 LF2, etc.

- Alloy Steel: Grades ASTM A182 F11, F22, etc.

- Duplex Steel: Grades UNS S31803, S32205, etc.

- Super Duplex Steel: Grades UNS S32750, S32760, etc.

Types of EN1092-1 Flanges

- EN 1092-1 Type 01 Flange (Plate Flange)

- Designed for low-pressure applications.

- Economical and easy to install.

- EN 1092-1 Type 02 Flange (Loose Flange)

- Used with lap joint stub ends.

- Suitable for frequent dismantling and inspection.

- EN 1092-1 Type 05 Flange (Blind Flange)

- Perfect for sealing off pipelines.

- Ensures safety during maintenance.

- EN 1092-1 Type 11 Flange (Welding Neck Flange)

- Designed for critical high-pressure and high-temperature systems.

- Features a long hub for stress distribution.

- EN 1092-1 Type 12 Flange (Hubbed Slip-On Flange)

- Combines slip-on flange convenience with enhanced strength.

- EN 1092-1 Type 13 Flange (Socket Weld Flange)

- Enables smooth and secure connections for smaller diameter pipelines.

Manufacturing Process for EN1092-1 Flanges

Our manufacturing process combines advanced technology and skilled craftsmanship to ensure consistent quality.

- Material Selection: Premium raw materials are sourced and inspected for compliance with standards like ASTM, ASME, and EN.

- Cutting and Shaping: Precision CNC machines shape the raw material into flange components with exact dimensions.

- Heat Treatment: Heat treatment enhances mechanical properties like strength, toughness, and corrosion resistance.

- Forging: Flanges are forged to achieve a uniform grain structure and superior durability.

- Machining: Final dimensions are achieved using advanced CNC lathes and milling machines.

- Surface Finishing: Flanges are polished and coated to ensure a smooth surface and added corrosion resistance.

Testing Procedures for EN1092-1 Flanges

We adhere to rigorous quality assurance protocols to guarantee the performance and safety of our flanges.

- Chemical Analysis: Ensures the material composition meets specified standards.

- Mechanical Testing:

- Tensile Test: Measures strength and ductility.

- Hardness Test: Verifies material hardness to meet specifications.

- Non-Destructive Testing (NDT):

- Ultrasonic Testing (UT): Detects internal flaws or discontinuities.

- Magnetic Particle Inspection (MPI): Identifies surface cracks.

- Dimensional Inspection: Ensures compliance with EN1092-1 specifications.

- Hydrostatic Testing: Verifies the pressure-bearing capacity of flanges.

- Visual Inspection: Final inspection to identify any surface defects or irregularities.

Applications of EN1092-1 Flanges

- Oil & Gas: Ideal for pipelines carrying oil, gas, and derivatives.

- Petrochemical Plants: Suitable for handling corrosive chemicals.

- Power Generation: Designed for steam, condensate, and cooling water systems.

- Water Treatment: Used in desalination and wastewater plants.

- Industrial Machinery: Connects various components with leak-proof efficiency.

Why Choose Emirerri Steel?

- Exceptional Quality: Products are tested for durability, performance, and dimensional accuracy.

- Customization Options: Tailored solutions to meet specific operational needs.

- Worldwide Shipping: Efficient logistics to deliver products globally.

- Technical Expertise: Backed by a team of skilled professionals for support.

- Competitive Pricing: High-quality products at cost-effective rates.

At Emirerri Steel, we are dedicated to providing world-class EN1092-1 Flanges, including Type 01, Type 02, Type 05, Type 11, Type 12, and Type 13 Flanges, that meet your exact specifications. Reach out to us today for inquiries, technical details, or customized orders.

Partner with Emirerri Steel for dependable and high-performing flange solutions.