Metalworking lathes are indispensable tools in the manufacturing and engineering industries, known for their precision, versatility, and ability to shape complex metal components. In this comprehensive guide, we will explore the world of metalworking lathes, delve into their applications, and highlight the role of Complete Machine Tools in offering high-quality lathes that meet the diverse needs of modern industries. Our aim is to provide an SEO-friendly overview that ranks high on Google for the keyword "metalworking lathe."

Understanding Metalworking Lathes

What is a Metalworking Lathe?

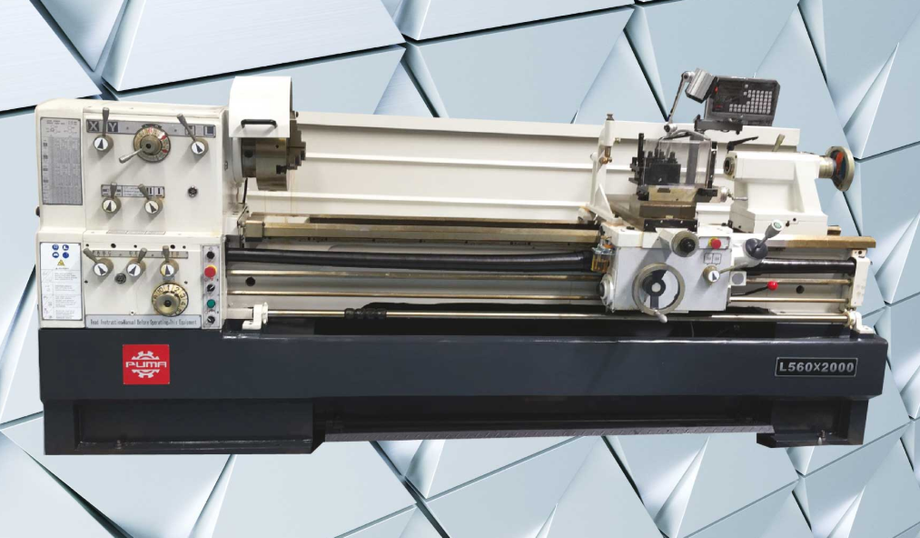

A metalworking lathe is a machine tool used to shape metal workpieces by rotating them against a cutting tool. The primary function of a metalworking lathe is to produce cylindrical parts, but it can also perform tasks such as drilling, knurling, and threading. The precision and accuracy of metalworking lathes make them essential for creating intricate components in industries like aerospace, automotive, and manufacturing.

Types of Metalworking Lathes

There are several types of metalworking lathes, each designed to cater to specific applications:

-

Engine Lathes: These are versatile and commonly used lathes suitable for general-purpose turning, facing, and threading operations.

-

Turret Lathes: Equipped with a turret tool post, these lathes facilitate rapid tool changes, making them ideal for high-volume production.

-

CNC Lathes: Computer Numerical Control (CNC) lathes offer automation and precision, allowing for complex machining tasks with minimal human intervention.

-

Toolroom Lathes: These lathes are designed for precision work with a focus on tool-making and prototyping.

-

Bench Lathes: Smaller in size, these lathes are suitable for light-duty work and are often used in educational settings and hobby workshops.

Key Features of Metalworking Lathes

Precision and Accuracy

Metalworking lathes are renowned for their precision and accuracy. The ability to achieve tight tolerances ensures that parts meet exact specifications, reducing waste and enhancing product quality.

Versatility in Operations

A metalworking lathe is capable of performing a wide range of operations, including turning, facing, drilling, boring, and threading. This versatility makes it a valuable asset in any workshop or manufacturing facility.

Advanced Technology Integration

Modern metalworking lathes, especially CNC lathes, incorporate advanced technology such as computer control, automation, and real-time monitoring. This integration enhances efficiency, reduces setup times, and allows for the production of complex geometries.

The Role of Complete Machine Tools in Metalworking Lathe Solutions

Complete Machine Tools has established itself as a leader in providing top-quality metalworking lathe solutions that cater to the diverse needs of industries worldwide. Here's how Complete Machine Tools stands out in the competitive landscape:

Extensive Product Range

Complete Machine Tools offers an extensive inventory of metalworking lathes, including engine lathes, CNC lathes, and turret lathes. Their selection ensures that customers can find the perfect lathe for their specific applications, whether for small-scale operations or high-volume production.

Commitment to Quality

Quality is a cornerstone of Complete Machine Tools' offerings. By partnering with reputable manufacturers and conducting rigorous quality checks, they ensure that every metalworking lathe meets high standards of performance, durability, and precision.

Customization and Tailored Solutions

Recognizing that industries have unique requirements, Complete Machine Tools provides customization options to tailor lathes according to customer needs. This flexibility allows clients to optimize their machining processes and achieve desired outcomes.

Expertise and Support

Complete Machine Tools is committed to providing exceptional customer service and support. Their team of experts offers guidance on selecting the right metalworking lathe, along with training and maintenance support to ensure optimal performance and longevity.

Applications of Metalworking Lathes in Various Industries

Aerospace Industry

In the aerospace sector, metalworking lathes are used to manufacture precision components such as turbine blades, engine parts, and structural elements. The high precision and accuracy of lathes are crucial for meeting the stringent safety and performance standards of the industry.

Automotive Industry

Metalworking lathes play a vital role in the production of automotive components, including engine parts, transmission systems, and suspension components. The ability to produce complex geometries and achieve tight tolerances makes lathes indispensable in automotive manufacturing.

Manufacturing and Engineering

In general manufacturing and engineering, metalworking lathes are used for a wide range of applications, from prototyping and tool-making to mass production. Their versatility and precision contribute to efficient and cost-effective operations.

Educational and Hobbyist Use

Metalworking lathes are also popular in educational settings and among hobbyists. They provide hands-on experience in machining and offer opportunities for creative projects and experimentation.

The Future of Metalworking Lathes

As industries continue to evolve, metalworking lathes are poised for further advancements and innovations. Key trends shaping the future of metalworking lathes include:

Automation and Industry 4.0

The integration of automation and Industry 4.0 technologies will enhance the capabilities of metalworking lathes. IoT connectivity, real-time data monitoring, and smart machining will optimize efficiency and reduce downtime.

Sustainable Manufacturing

With a focus on sustainability, future metalworking lathes will incorporate eco-friendly practices, such as energy-efficient designs and reduced material waste. Complete Machine Tools is dedicated to offering sustainable solutions that align with environmental goals.

Enhanced Precision and Innovation

Advancements in precision engineering and materials will lead to the development of metalworking lathes capable of achieving even higher levels of accuracy and innovation. Complete Machine Tools remains at the forefront of providing cutting-edge solutions to meet evolving industry demands.

Conclusion: Your Trusted Partner in Metalworking Lathe Solutions

In the dynamic world of metalworking lathes, Complete Machine Tools stands out as a trusted partner, offering high-quality products and exceptional service. By understanding the diverse needs of industries and providing innovative solutions, Complete Machine Tools is well-positioned to lead the industry into the future. With a focus on quality, customization, and customer satisfaction, Complete Machine Tools is the go-to choice for all your metalworking lathe needs.