How Is a Rotomolded Cooler Box Made?

The rotomolded cooler box is a very representative product of the rotational molding process. The rotomolded high-strength shell, safe rounded corners, and hollow foam processing make the rotomolded cooler box stand out among other types. Here follow us to see how a foam filled cooler box is made!

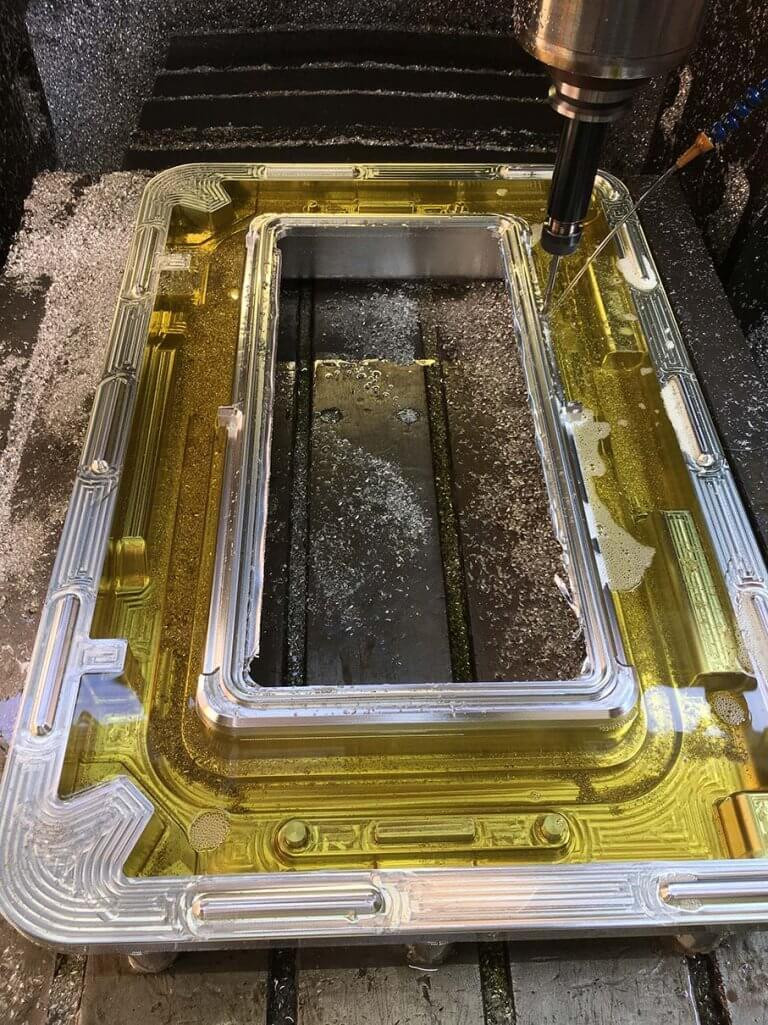

Step 1 : Making rotational mold

CNC milled from a forged aluminum block directly and casting are both good choices. The former has higher strength and smooth surface, and the latter can also have good quality after CNC processing of the surface.

After mold texture making and frame installing, a cooler box rotational mold is completed.

Step 2 : Making casting foaming molds

Since the foaming mold only plays a fixed role, we usually use the casting process to make it. The inner surface is also processed by CNC to ensure that the inner wall of the mold is flat and smooth, and the outer surface is simple and clean.

Step 3 : Thermoforming

Pour raw materials into the rotomolding mold, add anti-UV agent, etc., send the mold to the oven for high temperature heating and rotate, cool and demould after molding. The inner and outer walls of the cooler box are in a hollow state now.

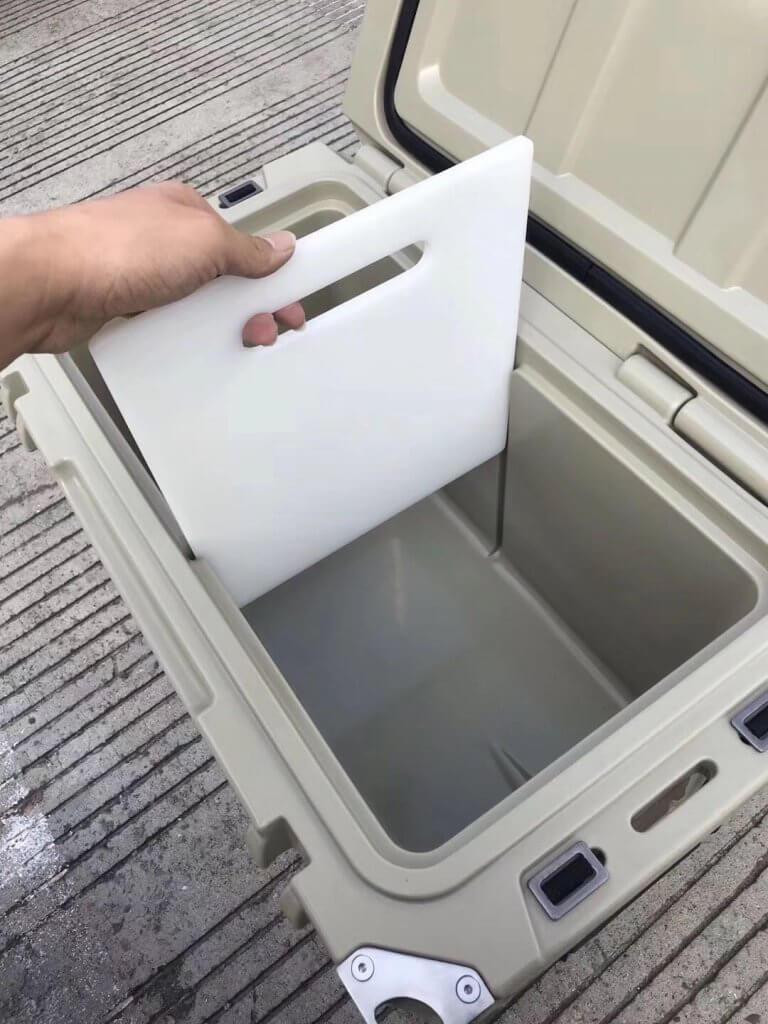

Step 4 : Filling foam

Fix the cooler box into the foaming mold, fill it with foam, and take it out after curing to get the final cooler box product.