Introduction

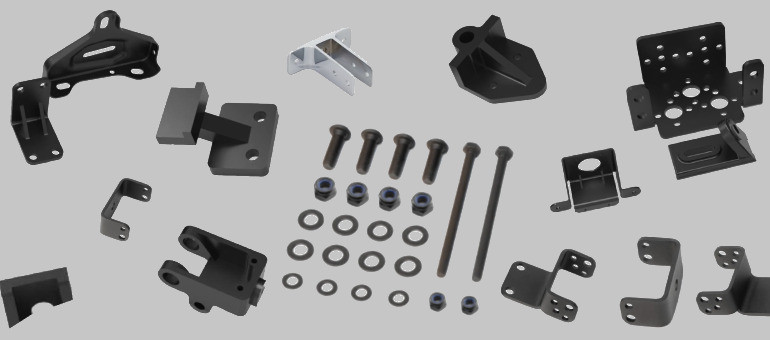

Manufacturing is efficiency- and precision-based with a bias towards being innovative. Frame Bracket Spacer, and all components of the integrated component in the way they assist in structural composition and facilitate right spacing and aligning to be feasible for the rest of the components.

The role they play, the manufacturing processes used in their creation, and their application across industries will be discussed in this blog.

Understanding the Elements

1. Frame

A frame is a basic structural component utilized in the majority of machinery, vehicles, and equipment for stabilizing and support purposes. Frames are utilized across a wide range of automobile bodies, construction machines, electrical enclosures, and furniture.

2. Bracket

Made-to-order brackets, or L-shaped brackets, are utilized to support or mount components. They are utilized in every industry, ranging from heavy equipment to electronics. They are utilized mostly to support components, giving strength and stiffness to most applications.

3. Spacer

Spacers are employed to provide space between machine parts. They are employed to obtain alignment, minimize friction, and protect against vibration or misalignment damage. Spacers may be fabricated from different materials such as metals, plastics, and composites.

4. Outside Considerations

In the manufacturing procedure of spacers, brackets, and frames, extrinsic parameters like material selection, environment, and load-carrying capacity are paramount. These need to be addressed by manufacturers and engineers to obtain functionality and durability.

Manufacturing Process

1. Material Selection

Material selection for Frame Bracket Outside provides strength, weight, and cost to spacers, brackets, and frames. Some of the most common materials used in manufacturing are:

● Steel: Has the highest strength and toughness at heavier weight.

● Aluminium: Lightweight and strong.

● Plastic: Multi-functional and low cost.

● Carbon Fibre: High strength-to-weight ratio and lightweight.

2. Design & Prototyping

Parts are created prior to mass production by manufacturers through Computer-Aided Design (CAD) software. It is accomplished:

● Visualization of the final product.

● Detection of possible defects.

● Optimization of material use.

● Verification of compatibility of parts with other components.

Prototyping, typically through 3D printing or CNC machining, enables engineers to physically test the design prior to mass production.

3. Manufacturing Techniques

The process of manufacturing varies according to the component and material. The following are processes most commonly employed:

A. Cutting & Shaping

● Laser Cutting: Employed for precise cutting of metal sheets.

● Waterjet Cutting: Employed to cut without applying heat.

● Plasma Cutting: Employed for cutting thick metal sheets.

● Injection Moulding: Employed for plastic spacers and brackets.

B. Forming & Bending

● Press Braking: Employed for shaping sheet metal.

● Roll Forming: Continuous bending of metal strips.

C. Joining & Assembly

● Welding: Utilized to join bracket and metal frame.

● Bolting & Riveting: Creates a temporary joint.

● Adhesives & Fasteners: Generally applied to light work.

D. Machining

● CNC Milling: Utilized to accurately machine.

● Turning & Grinding: Utilized in spacers requiring accurate measurement.

4. Surface Finishing

In order to impart strength as well as appearance, a variety of different finishing processes are utilized:

● Powder Coating: Leaves a hard, smooth finish.

● Anodizing: Done on aluminium with the hope of finding out corrosion resistance.

● Galvanizing: Zinc-plated metal sheets for protective reasons.

● Polishing: Gives a smoother finish to the metal part.

5. Quality Control & Testing

Products are strictly tested prior to appearing in the market:

● Dimensional Accuracy Tests: Through the use of coordinate measuring machines (CMMs).

● Load Testing: For strength testing and endurance testing.

● Corrosion Resistance Testing: Environmental simulation conditions.

● Vibration & Stress Testing: Providing stability for uses such as the aerospace and automotive industries.

Uses in Other Sectors

1. Automotive Industry

● The backbone of the car chassis is constructed using structural frames.

● Components such as radiators, batteries, and exhausts are supported on brackets. Spacers support wheels, and suspension function is maintained.

2. Aerospace Industry

● Light aluminium and carbon fibres are utilized as plane structure.

● Avionics and structural panels are held by brackets.

● Spacers control thermal expansion differences.

3. Electronics & Telecommunications

● Brackets support mounting hardware and PCBs.

● Spacers control air flow and insulation.

● Frames are made up of networking hardware and servers.

4. Construction & Infrastructure

● Steel construction frames cover the majority of bridges and buildings.

● Brackets are utilized by electrical conduits and HVAC.

● Spacers are utilized to align reinforcement bars in concrete structures.

5. Medical Equipment

● Surgical and diagnostic equipment is supported structurally by frames.

● Brackets stabilize moving components in medical equipment.

● Spacers are employed to place orthopedic and prosthetic appliances in proper position.

Manufacturing Challenges

● Reducing Material Waste: Optimum use of raw material to save costs and environmental degradation.

● Accuracy & Tolerance Challenges: Maintaining close tolerances for demanding applications.

● Automation vs. Hand Processes: Harmonious combination of cost-effective automation and skilled hands.

● Supply Chain Disruptions: Remaining steadfast with a robust material supply chain and logistics.

● Compliance with Regulation: Adhering to industry standards for hardness and safety.

● New Trends in Frame, Bracket, and Spacer Manufacturing

● Smart Manufacturing: Use of IoT and AI to monitor the process in real time and optimize the process.

● Sustainable Materials: Greater use of recycled metal and bioplastics in manufacturing.

● New 3D Printing: Reducing prototyping time and producing complex shapes.

● Nanotechnology Coatings: Enhancing part strength and abrasion resistance.

● Modular Design Approaches: Facilitating further customizations of products.

Conclusion

Frames, spacers, and brackets are small pieces of work, but their impact is immensely large in industries, providing strength, alignment, and the best performance. Manufacturing such products involves several processes, ranging from material selection to cutting, shaping, machining, surface treatment, and quality inspection. With the advancement of technology, the production of such tiny products also improves, offering space for effective and eco-friendly production methods.

Awareness of the intricacy of such products and production increases their producers' ability to produce more effectively, reduce wastage, and improve product quality. Motor vehicle, aircraft, building, or medical applications frames, brackets, and spacers cannot be overstated in value in terms of contribution and therefore constitute the pillars of contemporary engineering and industrial design.

Also Read: What is Die Casting: Process, Materials, and Types?