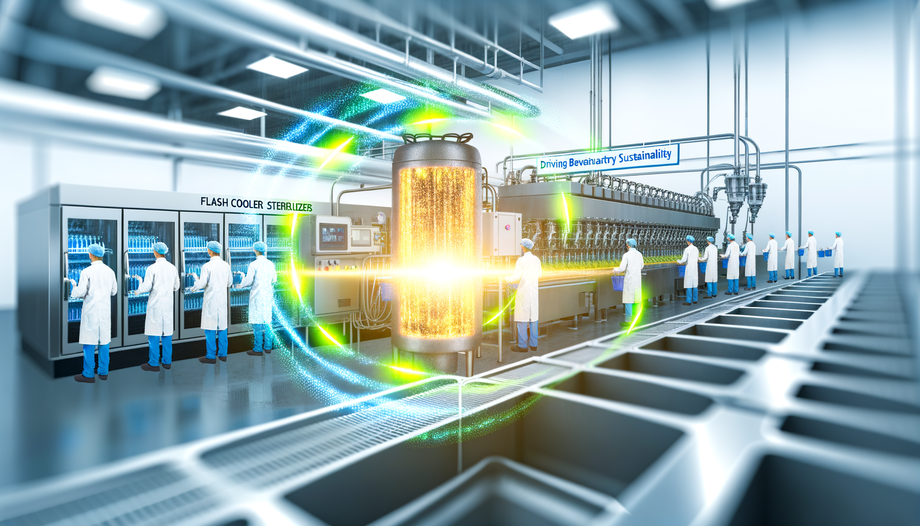

In an era where climate change and environmental sustainability loom large, industries worldwide are rethinking their processes and practices to align with a greener future. The beverage industry, a significant player in global economic activity and resource consumption, is not immune to this transformation. A particular innovation taking center stage in this sustainable shift is the Flash Cooler Sterilizer, a technology marrying efficiency with eco-sensitivity.

The Rise of Sustainability in Beverage Production

The notion of sustainability goes beyond just a buzzword in today's industrial landscape—it's a necessity. For the beverage industry, this translates into:

- Reducing the Carbon Footprint: Minimizing emissions from production activities.

- Resource Conservation: Efficient water, energy, and ingredient usage.

- Waste Management: Implementing circular economy principles and minimizing by-product waste.

- Ethical Sourcing: Ensuring that ingredients are sourced sustainably and ethically.

These mandates have fueled a burgeoning interest in technologies that pave the way for greener manufacturing. This is where the flash cooler sterilizer steps in.

Flash Cooler Sterilizers: A Brief Overview

The flash cooler sterilizer is an apparatus designed to swiftly cool and sterilize liquid products, making it a viable solution for beverage producers in need of cost-effective and rapid processing. It encompasses a heat exchange mechanism that instantly lowers the temperature of liquids, which helps in maintaining the quality and taste integrity of beverages while meeting hygiene standards.

Why Flash Cooler Sterilizers?

-

Energy Efficiency:

- Rapid Heat Exchangers: With flash cooling, beverages are rapidly cooled in a contained environment, significantly reducing the time and energy consumed in traditional cooling methods.

- Minimal Heat Loss: The system's design ensures that any heat produced during production is tactfully utilized, thereby preventing waste.

-

Improved Product Quality:

- Nutrient Preservation: Flash cooling ensures that sensitive vitamins, flavors, and aromas are preserved, offering consumers a fresher and more authentic taste profile.

- Enhanced Stability: By minimizing exposure to air and environmental contaminants, products enjoy enhanced shelf stability.

-

Reduced Water Consumption:

- In comparison to traditional methods, flash coolers have sophisticated water recirculation systems that compress water requirements, ensuring optimal usage.

The Green Advantages of Flash Cooler Sterilizers

-

Lower Greenhouse Gas Emissions:

- Deployment of flash cooling results in reduced energy consumption. Less energy tranlates directly to lesser greenhouse gas emissions.

-

Waste Heat Recovery:

- Waste heat from the cooling process can be captured and reused in other production areas, thereby promoting a circular processing system.

-

Minimal Chemical Usage:

- By prioritizing physical methods of sterilization, flash coolers reduce or completely eliminate the need for harsh chemical sterilizers.

Making the Business Case: ROI and Beyond

Increased Competitiveness:

- With consumers becoming more environmentally conscious, brands that embrace sustainable practices witness enhanced consumer loyalty.

Regulatory Alignment:

- Governments worldwide are tightening regulations concerning energy and resource efficiencies. Adopting technologies like a flash cooler positions companies as proactive and responsible, potentially easing the burden of compliance.

Reduced Operational Costs:

- The initial investment in flash coolers might seem steep, but the long-term savings due to reduced energy and water usage, coupled with enhanced product stability, often result in an impressive ROI.

Navigating Challenges: Overcoming Implementation Hurdles

Despite the promising benefits, adopting flash cooler sterilizers comes with challenges:

- Infrastructure Modifications: Factories might need significant retrofitting to accommodate new technology.

- Training Needs: Workforce must be adequately trained to handle and maintain sophisticated tech infrastructures.

- Upfront Investment: Initial costs might deter smaller players without adequate financing.

The Road Ahead

The beverage industry's shift towards sustainable and energy-efficient production practices is an integral part of global sustainable development goals. Flash cooler sterilizers, with their multifaceted benefits, offer a gleaming ray of hope for manufacturers striving to balance economic viability with ecological responsibility.

As sustainability becomes an industry staple, it isn't just a matter of staying ahead in the market—it's about safeguarding our planet. As beverage companies continue to zero in on green technologies, those who embrace innovations like flash cooler sterilizers will not only benefit from newfound efficiencies but will lead the charge in a greener industry revolution.

Conclusion

In the grand tapestry of beverage production, flash cooler sterilizers stand out, knitting together the threads of sustainability, efficiency, and quality. Spurring technological evolution and sustainability is a joint effort and the beverage sector, equipped with these innovative tools, is poised on the brink of transformative change. Here's to a future where every sip is a toast to sustainability!

Explore Comprehensive Market Analysis of Flash Cooler Sterilizers Market

SOURCE -- @360iResearch