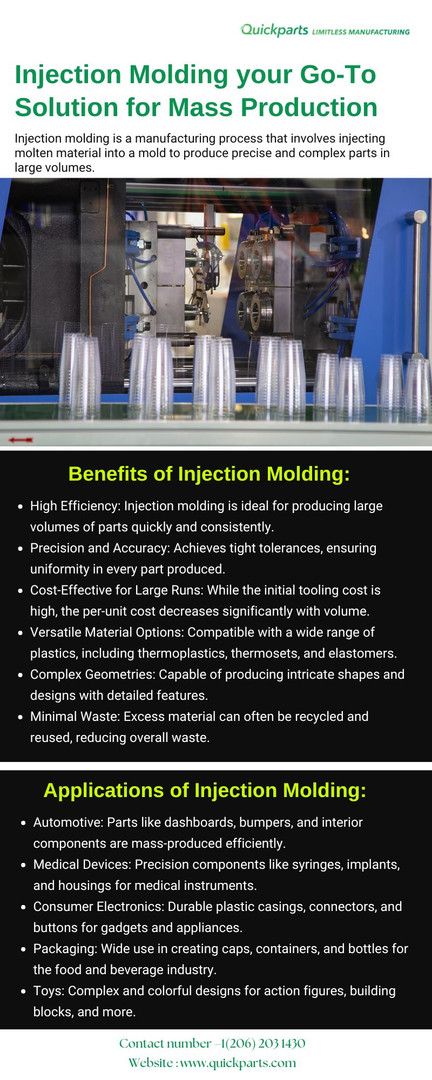

Injection molding is a manufacturing process that involves injecting molten material into a mold to produce precise and complex parts in large volumes.

Benefits of Injection Molding:

High Efficiency: Injection molding is ideal for producing large volumes of parts quickly and consistently.

Precision and Accuracy: Achieves tight tolerances, ensuring uniformity in every part produced.

Cost-Effective for Large Runs: While the initial tooling cost is high, the per-unit cost decreases significantly with volume.

Visit us here: https://quickparts.com/