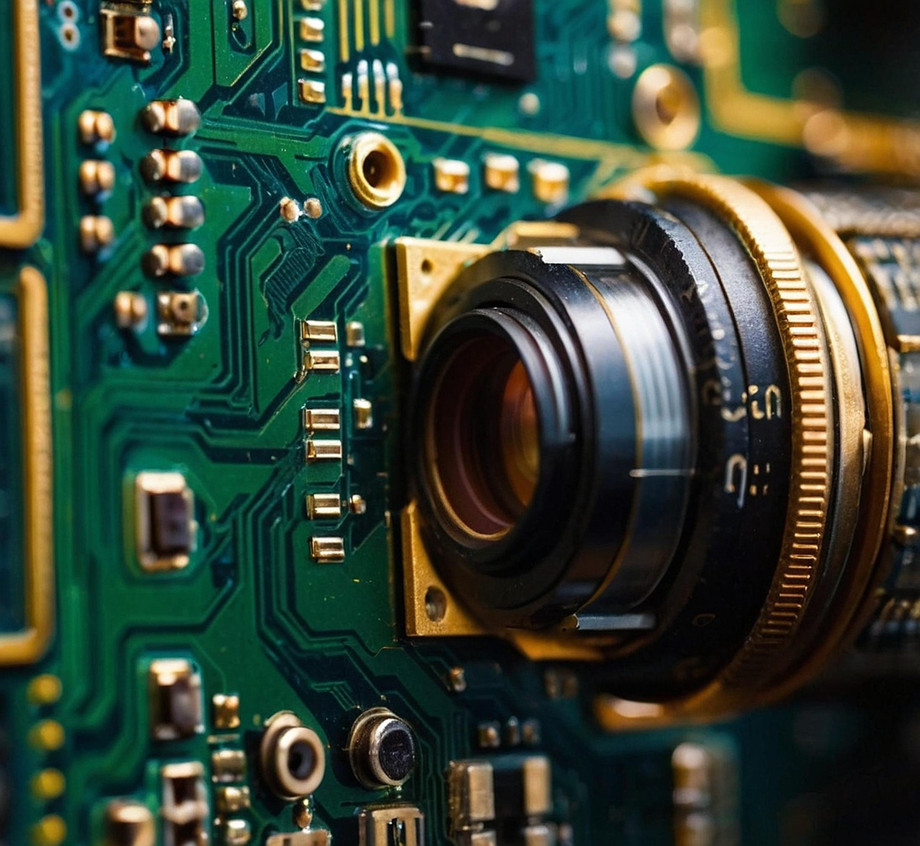

The automotive manufacturing industry is evolving rapidly, driven by the need for more efficient, safe, and sustainable production processes. One of the most influential technologies shaping the future of automotive manufacturing is camera embedded systems. These systems are being integrated into various stages of production to streamline operations, enhance quality control, and increase overall productivity.

Camera embedded systems are revolutionizing how manufacturers approach the challenges of modern automotive production. With capabilities that enable high-precision image capture, real-time processing, and advanced data analytics, they are becoming indispensable in maintaining the industry's competitive edge. In this blog, we explore how these systems are driving efficiency and transforming automotive manufacturing.

The Role of Camera Embedded Systems in Automotive Manufacturing

Camera embedded systems are highly specialized technologies that combine sensors, image processors, and software in compact, integrated units. These systems can capture high-resolution images and videos of manufacturing processes, vehicles, and components in real time. By analyzing this data, they provide manufacturers with actionable insights to optimize various production tasks.

Key Applications of Camera Embedded Systems

-

Quality Inspection and Defect Detection

Quality control is a critical aspect of automotive manufacturing. Embedded camera systems are used for detailed inspection of parts and components, identifying defects such as surface irregularities, dimensional inaccuracies, and misalignments. By automating this process, manufacturers can ensure higher precision and consistency compared to manual inspections. Camera systems equipped with machine learning algorithms can even predict potential defects before they occur, reducing waste and downtime. -

Robotic Vision Systems

In automotive assembly lines, robots play a significant role in handling complex and repetitive tasks. Embedded camera systems are essential for enabling vision-guided robotic systems. These systems provide real-time visual feedback to robots, allowing them to accurately position and assemble parts. This capability improves the speed and accuracy of the manufacturing process, while reducing the risk of errors that could lead to costly rework or production delays. -

Supply Chain and Inventory Management

Camera embedded systems are also being used to monitor supply chains and manage inventory in real time. These systems can scan and track components throughout the production line, ensuring that the right parts are delivered to the right location at the right time. This not only prevents bottlenecks in the assembly process but also helps reduce excess inventory, contributing to cost savings and more efficient resource utilization. -

Autonomous Vehicle Testing and Validation

As automotive manufacturers increasingly focus on developing autonomous vehicles, camera embedded systems play a critical role in testing and validation. These systems are used to capture and analyze data from vehicle sensors and onboard cameras, enabling manufacturers to test the performance of self-driving cars in simulated and real-world environments. The data collected helps ensure that autonomous systems are reliable and safe for public use, facilitating faster development cycles and improving vehicle safety.

Benefits of Camera Embedded Systems in Automotive Manufacturing

The integration of camera embedded systems in automotive manufacturing offers numerous benefits that contribute to increased efficiency, enhanced safety, and overall productivity.

1. Improved Accuracy and Precision

One of the primary advantages of camera embedded systems is their ability to perform high-precision tasks with minimal error rates. In tasks like welding, painting, and assembly, camera systems ensure that each component is placed and processed with exact accuracy. This reduces the likelihood of defects and ensures that vehicles meet stringent quality standards.

2. Faster Production Cycles

With camera systems automating critical tasks such as inspection, inventory tracking, and robotic guidance, manufacturers can significantly speed up their production cycles. These systems operate continuously and with minimal human intervention, reducing the time required to complete each stage of manufacturing. The result is a faster, more streamlined production process that allows companies to meet growing demand without compromising on quality.

3. Enhanced Safety

Automotive manufacturing environments often involve potentially hazardous tasks, such as working with heavy machinery or handling dangerous chemicals. Camera embedded systems enhance safety by enabling real-time monitoring of workers and machinery. These systems can detect unsafe conditions or improper use of equipment, alerting operators to potential risks before accidents occur. Additionally, vision-guided robots reduce the need for human workers to engage in physically demanding or dangerous tasks, further enhancing workplace safety.

4. Data-Driven Decision Making

The data captured by camera embedded systems provides manufacturers with valuable insights into their operations. By analyzing this data, companies can identify inefficiencies, predict equipment failures, and optimize production processes. For instance, real-time image analysis can detect when a machine is operating outside of its optimal parameters, allowing for predictive maintenance and reducing downtime. This data-driven approach leads to more informed decision-making, ensuring that resources are used efficiently and that production targets are met.

Challenges and Considerations for Implementing Camera Embedded Systems

While camera embedded systems offer significant benefits, there are challenges associated with their implementation. Understanding and addressing these challenges is critical for manufacturers looking to maximize the return on investment from these systems.

1. Integration with Existing Systems

One of the main challenges in adopting camera embedded systems is integrating them with existing production technologies. Manufacturers need to ensure that the new systems can seamlessly communicate with other machines and software on the production line. This requires careful planning and collaboration between IT, engineering, and manufacturing teams.

2. Initial Investment and ROI

Camera embedded systems can be expensive to implement, particularly for small and medium-sized manufacturers. However, the long-term benefits in terms of efficiency, cost savings, and quality improvements often justify the initial investment. Companies should perform a thorough cost-benefit analysis to determine the potential return on investment (ROI) before committing to a large-scale deployment.

3. Skill Gaps and Workforce Training

The successful adoption of camera embedded systems requires a skilled workforce capable of operating and maintaining these technologies. Manufacturers need to invest in training programs to ensure that their employees are proficient in using and troubleshooting these systems. Additionally, collaboration with technology vendors and service providers can help bridge any skill gaps.

The Future of Camera Embedded Systems in Automotive Manufacturing

As automotive manufacturing continues to evolve, camera embedded systems will play an increasingly important role in driving innovation and efficiency. Advancements in artificial intelligence (AI), machine learning, and edge computing will further enhance the capabilities of these systems, enabling them to perform even more complex tasks with greater accuracy and speed.

In the future, we can expect to see camera systems that are fully integrated with the Industrial Internet of Things (IIoT), enabling seamless communication between machines, robots, and humans on the factory floor. This will lead to even greater levels of automation and efficiency, as well as more flexible and agile manufacturing processes.

Conclusion

Camera embedded system solutions are transforming the automotive manufacturing industry by driving efficiency, improving quality, and enhancing safety. By leveraging the power of real-time image capture, data analysis, and automation, manufacturers can optimize their operations, reduce costs, and stay competitive in a rapidly changing market.

As the technology continues to evolve, manufacturers that embrace camera embedded systems will be well-positioned to lead the way in producing the next generation of vehicles with greater speed, precision, and reliability. Investing in these systems now will provide long-term benefits, not only for the company’s bottom line but also for the future of the automotive industry.

To Know More About embedded systems