What is MEMS? MEMS (Micro-Electro-Mechanical System) refers to a miniaturized device or system that integrates micro-mechanical components, micro-actuators, signal processing, and control circuits. The fabrication process of micro-mechanical structures involves photolithography, ion beam etching, chemical etching, and wafer bonding. Electrodes are also fabricated on the mechanical structures for electronic control.

A MEMS chip is an integrated circuit that combines micro-mechanical structures with electronic components. It is fabricated using micro- and nano-fabrication techniques to create tiny mechanical elements on a chip surface, which are then interconnected with electrical circuits. These miniature mechanical structures can perform various functions such as sensing, measuring, controlling, and actuating. MEMS chips are typically made of silicon due to its excellent mechanical properties and well-established microfabrication processes. The manufacturing process involves photolithography, thin film deposition, ion etching, and wet etching to precisely construct the tiny structures on the chip.

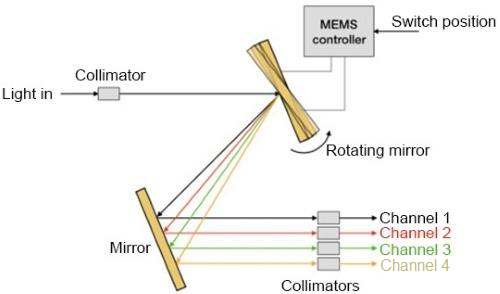

A MEMS optical switch involves etching tiny mirrors onto a silicon wafer. By applying electrostatic or electromagnetic forces, the mirror array can rotate, thereby altering the propagation direction of the incoming light and achieving optical path switching. The routing of optical waves in a MEMS optical switch is accomplished through external control signals and corresponding high/low voltage levels that control the elevation of the internal mirrors. These switches integrate micro-machines, micro-actuators, signal processing, and control circuits to enable efficient optical signal management.

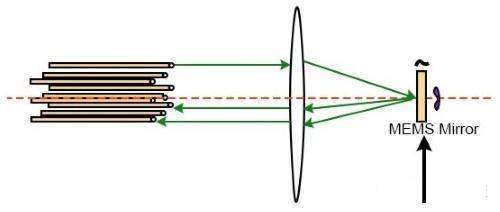

Figure 1. A schematic diagram of a MEMS optical switch, illustrating its basic components and optical path.

The core components of a MEMS optical switch are tiny mirrors etched onto a silicon wafer. These micromirrors can be rotated using electrostatic or electromagnetic forces, altering the direction of incoming light and effectively switching the optical path on or off.

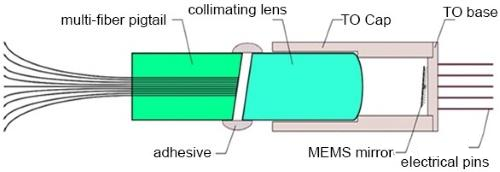

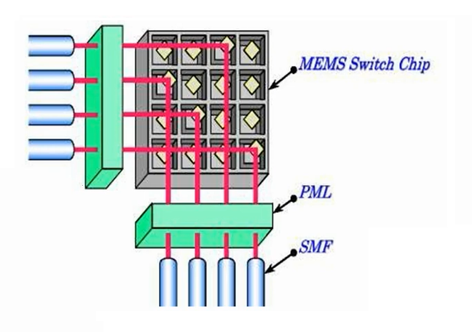

Figure 2. A schematic diagram showing the arrangement of components in MEMS optical switch

MEMS optical switches typically have two types of port configurations:

Matrix (symmetric): Multiple input and output ports arranged in a matrix format (e.g.,4x4, 8x8, MxN).

Fan-out (asymmetric): A single input port and multiple output ports arranged in a fan-out pattern (e.g., 1x2, 1x4, 1xN).

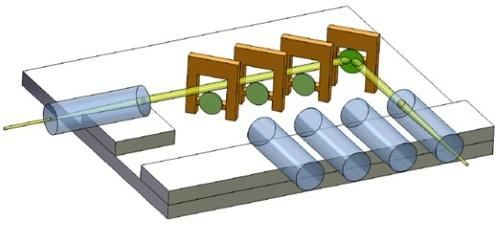

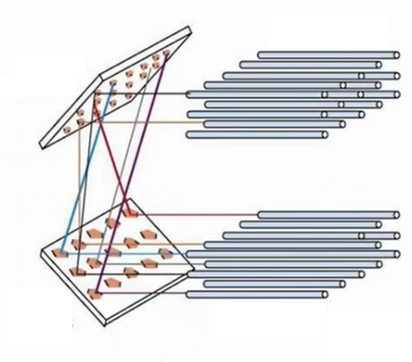

Figure 3. A schematic diagram showing the arrangement of MEMS torsional mirrors, collimating lenses, and multiple fiber pigtails in a 1xN MEMS optical switch.

A MEMS optical switch operates by directing incoming optical signals to a micro-electromechanical system (MEMS) mirror. This mirror, controlled by external electrical signals, can be tilted or rotated to redirect the light towards the desired output port.

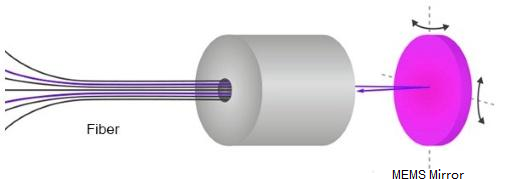

Figure 4. A schematic diagram showing the optical path and mirror movement in a MEMS-based optical switch.

Figure 5. A schematic diagram showing the optical path of a MEMS optical switch from input to output fiber.

Based on the spatial structure, MEMS optical switches can be categorized into two main types:

2D switches: In these switches, the mirrors rotate within a single plane. When the micromirror is horizontal, light passes through; when it's vertical, it reflects the light to the corresponding output port.

Figure 6. A schematic diagram depicting the physical structure of a 2D MEMS optical switch. It illustrates the rotation mechanism of the micromirror and how this movement alters the direction of the incident light, enabling switching between different output ports.

3D switches: These switches feature micromirrors capable of rotating in three-dimensional space, allowing for more complex optical routing. Two mirror arrays are commonly employed for input and output.

Figure 7: A schematic diagram depicting the physical structure of a 3D MEMS optical switch. It illustrates the dual-axis rotation mechanism of the micromirrors and how this movement enables precise control over the direction of the incident light, allowing for complex optical routing.