In recent years, the global shift towards renewable energy has prompted a multifaceted transformation in the manufacturing sector. As countries worldwide strive to reduce carbon footprints and combat climate change, the expansion of renewable energy technologies has taken center stage. This surge in demand has directly influenced the manufacturing landscape, particularly emphasizing the need for precision-formed components.

Precision-formed components play a critical role in ensuring the efficiency and durability of renewable energy systems. Whether used in wind turbine towers, solar panel frames, or hydroelectric generators, these components must meet meticulous standards. Is thermoplastic forming, particularly CNC tube bending, the answer to this growing demand?

The Rise of Renewable Energy

Renewable energy has moved from being a niche sector to a mainstream solution to global energy needs. Here's why:

- Government Policies and Incentives: Nations are incentivizing the sector with tax credits, subsidies, and supportive legislation to encourage investment in renewable technologies.

- Technological Advancements: Innovation in renewable technology is reducing costs and improving efficiency, making it increasingly viable as a mainstream energy source.

- Energy Independence: Countries are eager to reduce dependence on fossil fuels, seeking energy security through domestic renewable resources.

- Environmental Impact Awareness: With climate change effects becoming more pronounced, there's a heightened emphasis on sustainable energy solutions.

Demand for Precision-Formed Components

As renewable technologies evolve, so do their form and function requirements. The need for precision-formed components is critical for several reasons:

- Efficiency: Next-gen turbines and solar panels require tailor-made components that can withstand harsh environments and deliver energy efficiently.

- Durability: High-quality components contribute to the longevity and reliability of energy systems, reducing maintenance costs over time.

- Customization: Projects in diverse locations demand components adapted to specific geographic and climatic conditions.

Thermoplastic Forming in Focus

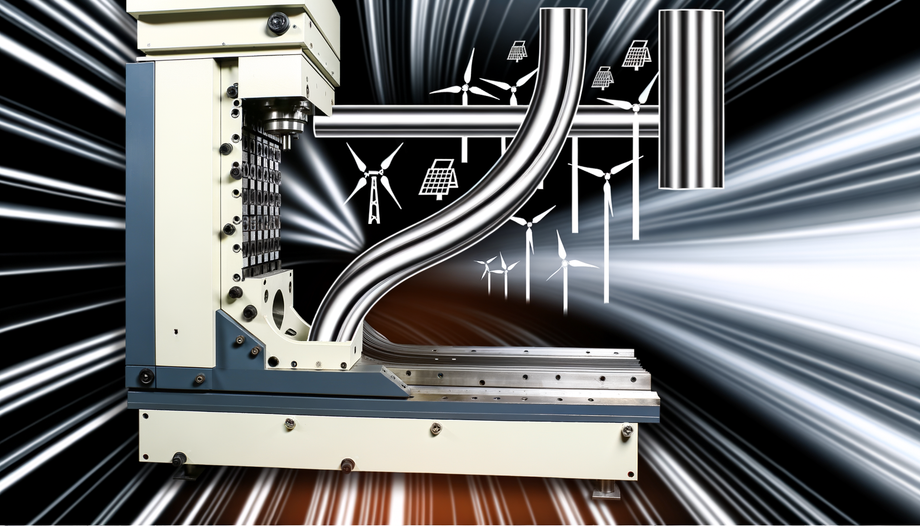

Among the various manufacturing techniques catering to the renewable sector, thermoplastic forming has emerged as a game-changer. The incorporation of CNC tube bending machines into this process has pushed the industry towards unprecedented precision.

CNC Tube Bending Meets Renewable Energy

The introduction of CNC tube bending in thermoplastic forming allows for more accurate, custom-tailored parts integral to renewable energy apparatus. Here's why it matters:

- Precision Engineering: This technology allows for tight tolerance levels, essential for components that must interlock seamlessly.

- Versatility: CNC tube bending machines can handle various materials, including lightweight thermoplastics that are increasingly preferred in modern renewable applications.

- Efficiency: By automating the bending process, production times decrease, rapidly meeting the increasing demand for renewable componentry.

Benefits to Renewable Energy Sector

- Reduced Weight and Cost: Thermoplastics are lighter and, when combined with CNC precision, reduce material waste, streamlining costs.

- Enhanced Performance: Lightweight components mean less strain on the overall device, optimizing performance.

- Greater Design Freedom: Complex geometries are easier to achieve, allowing for innovative solutions tailored to specific energy harvesting environments.

Real-World Applications

- Wind Turbines: Precision-formed tubes contribute to streamlined turbine structures that maximize energy conversion.

- Solar Projects: Frames and supports made from thermoplastics hold up better against corrosion at solar farms, particularly in coastal environments.

- Biomass Plants: Pipeline systems in biomass facilities benefit from durable, custom-fitted components.

How Manufacturers are Capitalizing

Manufacturers who have invested early in thermoplastic forming technologies have a competitive advantage. By offering bespoke solutions and adapting to the rapid increase in demand, they have positioned themselves as key players within the renewable ecosystem.

Conclusion: The Path Ahead

The growing need for renewable energy is reshaping industries far and wide, calling for innovative approaches in manufacturing. By embracing advanced techniques like CNC tube bending in thermoplastic forming, the industry is poised to meet the demands of sustainable energy head-on. As a result, manufacturers are not just participants but leaders in the environmental revolution.

As the pace of change quickens, aligning manufacturing capabilities with sustainable goals is not only a business imperative but a crucial contribution to a better future. This synergy between renewable energy needs and manufacturing capabilities promises to forge a resilient and efficient future, setting the stage for further innovation and expansion.

Stay tuned to watch this space evolve as the shift towards sustainability continues to transform the manufacturing landscape.

Explore Comprehensive Market Analysis of Thermoplastic Forming CNC Tube Bending Machine Market

SOURCE -- @360iResearch