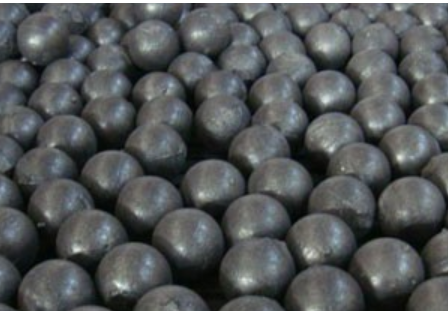

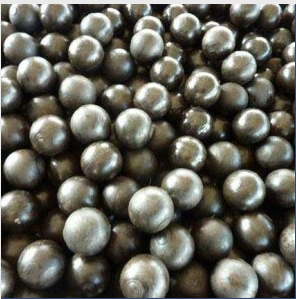

Grinding Media Balls Production and Its Benefits

Their grinding media ball is made of carbon steel and chrome alloy steel. Generally, carbon steel balls are used for common low-speed grain grinding, such as metal or chemical powders. For high-speed ball mill grinding processes such as paints, ink or resin powders, chrome alloy steel balls are commonly used for extended durability.

Because grinding media is always consumed on a large scale, cost and durability are the most important attributes. They have been focusing on creating cheap but durable grinding media for many years and are now able to offer the highest cost savings and most durable grinding media balls on the market. They offer their grinding media in a variety of results and formats to save every penny. Their specialty title and heat treatment processes guarantee excellent durability. They will be happy to create customized grinding media for any special grinding process.

Production of Grinding Media Ball

Grinding Media Ball product size has a significant impact on the performance of grinding plants in terms of distribution, energy consumption, and grinding costs. The figure below shows the main grinding costs for specific plants. Considering the contribution of grinding media ball costs to overall grinding costs, it is worthwhile to explore the possibility of reducing them.

experience in the mining, cement, thermal power and chemical industries, and the continued development of advanced grinding media ball technology, Company Grinding Media Ball Manufacturers are leading.

Company Expert is fully committed to providing you with the most efficient solution for your specific grinding needs. In the long run, the effectiveness of media ball grinding should be measured on the ground efficiently at the final cost of a ton of products. Company Advanced Manufacturing Systems and Materials are guaranteed to maintain diameter tolerances and proper configurations which are important for sustainable performance and long life of media ball grinding. Company forged steel Ball has a uniform hardness from the surface to the center, thus maintaining the finest wear properties to the smallest diameter. Grinding media ball not only has a hard outer layer for long life but also gives good impact resistance along with a hard, flexible core. All supplied grinding media balls are rigorously tested to ensure that they meet the specifications as per requirements.

Benefits

- Where Steel Grinding Media Looks Good:

- Need more wear and chemical resistance.

- It is important to generate heat for the grinding and scattering process.

- Pollution-free and rapid (dry/wet) grinding is important.

- Crushing and blending of heavy and hard materials are carried out.

- High pressure and impact grinding or crushing methods are used.

- Reducing the particle size and better dispersion of highly viscous liquids is required.