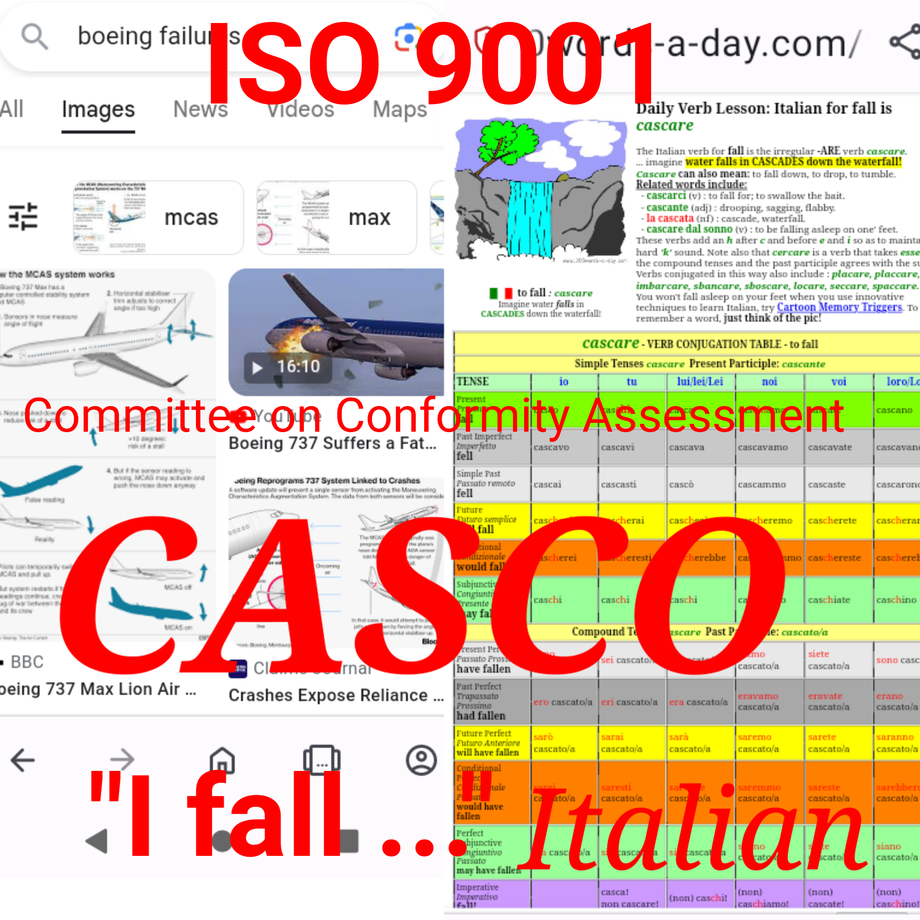

ISO 9001 CASCO

Boeing has had many glaring

technical failures lately.

From the inception of the Max8

Line... things have been going

WRONG.

Stupid things.

The MCAS system, designed

to stabilize a bad airframe.

Use of $9 dollar an hour

Indian "Software Engineers"

to implement and maintain it.

Absent documentation of MCAS

in flight manuals.

Failure to notify FAA of MCAS

in the plane's qualifications.

Missing or loose bolts on

Five current Max9 jets.

Emergency door blowout.

Nosewheel falling off of

a current, in-service,

Boeing 777.

Was the ISO STANDARDS

QUALITY CONTROL

A TROJAN HORSE ?

Examine this:

And realize:

If Boeing covered up

quality problems in

THEIR MANUFACTURING,

Then any of these listed

Qualifiers could allow

low quality steel fasteners

and "precision-strength" bolts !

Automakers and Truck makers

have suffered TOO..!

I think we must return

to an AMERICAN QUALITY STANDARD...

After all...

Air Force One

is a Boeing.

Boeing needs to hire

Field Seasoned Engineers

for it's management.

Not yuppie Globalist MBA's !!!!!

[ This page built with JPICedar v. j102123a Thurs, 1-25-2024 Time : 8:04a ]