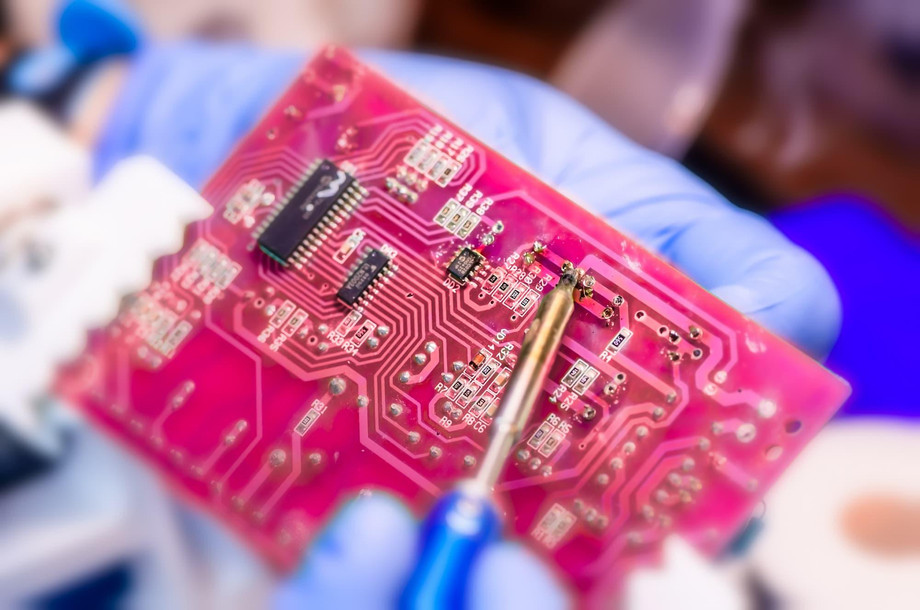

Embedded design is vital to industrial applications' usefulness and efficiency in the quickly changing technological world of today. Many contemporary industries rely heavily on embedded systems to provide the automation, control, and data processing capabilities that spur innovation and productivity. With a focus on important topics including embedded systems development, embedded systems operating systems, and embedded systems programming, this blog will examine the fundamentals of efficient embedded design for industrial applications.

Comprehending Embedded Design

Embedded design is the process of creating customized computer systems that perform certain functions inside larger mechanical or electrical systems. Unlike general-purpose computers, embedded systems are designed for specific purposes and can have constraints related to size, cost, and power consumption. These systems are necessary for industrial applications because they oversee operations, control machinery, and provide security.

Principles of Effective Embedded Design

1. Define clear requirements.

The first principle of effective embedded design is to define clear and concise requirements. This involves understanding the specific needs of the industrial application and outlining the system's functional and non-functional requirements. Clear requirements provide a roadmap for the design process, ensuring that the final product meets the intended objectives.

-

Functional Requirements: These define what the embedded system should do. For example, in an industrial automation system, functional requirements might include controlling motors, processing sensor data, and communicating with other systems.

-

Non-Functional Requirements: These outline how the system should perform its functions. This includes constraints on power consumption, response time, reliability, and environmental conditions.

2. Focus on robustness and reliability.

Industrial applications often operate in harsh environments and require systems that are robust and reliable. Effective embedded design must prioritize durability and stability to ensure continuous operation without failure. This involves selecting components that can withstand extreme temperatures, vibrations, and other environmental stresses.

-

Component Selection: Use industrial-grade components that meet the required specifications for durability and reliability.

-

Testing and Validation: Implement rigorous testing and validation processes to identify and address potential points of failure before deployment.

3. Optimize for real-time performance

Many industrial applications rely on real-time performance, where timely and deterministic responses to external events are critical. Effective embedded design must ensure that the system can process inputs and generate outputs within defined time constraints.

-

Real-Time Operating Systems (RTOS): Utilize RTOS to manage tasks with strict timing requirements. RTOS can prioritize tasks and allocate resources efficiently to meet real-time performance needs.

-

Embedded Systems OS: Select an embedded systems OS that supports real-time processing, low latency, and high throughput.

4. Emphasize security

Security is paramount in embedded design for industrial applications, as these systems are often connected to networks and exposed to potential cyber threats. Effective embedded design must incorporate robust security measures to protect against unauthorized access, data breaches, and other cyberattacks.

-

Encryption: Implement encryption techniques to protect data in transit and at rest.

-

Access Control: Use authentication and authorization mechanisms to restrict access to the system.

-

Firmware Updates: Ensure the ability to securely update firmware to address vulnerabilities and improve functionality.

5. Efficient Power Management

Industrial embedded systems must often operate within strict power constraints, particularly in remote or battery-powered applications. Effective power management is crucial to extending the operational life and reducing the overall cost of the system.

-

Low-Power Components: Select components designed for low power consumption.

-

Power-Saving Modes: Implement power-saving modes that reduce energy consumption during periods of inactivity.

-

Energy Harvesting: Explore energy harvesting techniques to supplement power from renewable sources, such as solar or vibration energy.

6. Scalability and Flexibility

Industrial applications may evolve over time, requiring embedded systems that can adapt to new requirements and technologies. Effective embedded design should prioritize scalability and flexibility to accommodate future changes.

-

Modular Design: Use a modular design approach that allows for easy upgrades and expansions.

-

Software Updates: Implement mechanisms for remote software updates to add new features or improve performance.

-

Embedded Systems Development: Develop a scalable architecture that can grow with the needs of the industrial application.

Embedded Systems Development

Embedded systems development involves the end-to-end process of designing, coding, testing, and deploying embedded systems. This process requires a deep understanding of hardware and software integration, as well as the specific requirements of the industrial application.

Key Steps in Embedded Systems Development:

-

Requirement Analysis: Define the system requirements based on the industrial application.

-

System Design: Create a detailed design that outlines the hardware and software components and their interactions.

-

Implementation: Develop the software and integrate it with the hardware.

-

Testing: Perform extensive testing to ensure the system meets the defined requirements and operates reliably.

-

Deployment: Deploy the system in the industrial environment and monitor its performance.

Embedded Systems OS

embedded systems OS is a specialized operating system designed for the unique needs of embedded systems. These operating systems provide the necessary infrastructure for managing hardware resources, executing applications, and ensuring real-time performance.

Features of Embedded Systems OS:

-

Real-Time Capabilities: Support for real-time scheduling and deterministic response times.

-

Resource Management: Efficient management of CPU, memory, and I/O resources.

-

Small Footprint: Optimized for limited memory and storage capacities.

-

Security: Built-in security features to protect against cyber threats.

Embedded Systems Programming

Embedded systems Programming involves writing software that runs on embedded systems. This requires knowledge of low-level programming languages, hardware interfaces, and real-time constraints.

Best Practices in Embedded Systems Programming:

-

Use Efficient Code: Write code that is optimized for performance and memory usage.

-

Hardware Abstraction: Use hardware abstraction layers to simplify hardware interactions and improve portability.

-

Code Testing: Implement thorough testing procedures to ensure code reliability and functionality.

-

Documentation: Maintain comprehensive documentation to support maintenance and future development.

Conclusion

Effective embedded design is crucial for the success of industrial applications, ensuring that systems are reliable, secure, and performant. By adhering to the principles outlined in this blog and focusing on key areas such as embedded systems development, embedded systems OS, and embedded systems programming, designers can create robust and scalable solutions that meet the demanding requirements of modern industries.

To Know More About embedded design