Heavy Equipment Fleet Maintenance: 7 Software Tools That Get the Job Done

Discover the Power of Real-Time Data for Your Construction Fleet Operations

Real-time data revolutionizes your construction fleet operations, offering unparalleled visibility and control. advanced fleet tracking installations. You'll utilize GPS, RFID, and cellular triangulation for precise location tracking, optimizing equipment utilization and productivity. Predictive maintenance strategies, powered by IoT sensors and machine learning, minimize downtime and extend machinery lifespan. You can monitor fuel consumption patterns, improve driving behavior, and optimize routes for enhanced efficiency. Automated safety and compliance systems guarantee regulatory adherence while providing instant incident reporting and analysis. By embracing data-driven decision-making, you'll cultivate a culture of continuous improvement, enhancing operational efficiency and risk management. Uncover how these technologies can change your fleet management approach

Key Takeaways

construction vehicle tracking system

construction vehicle tracking system- Real-time location tracking enhances operational efficiency, safety, and theft deterrence for construction equipment and materials.

- Data-driven decision-making improves fleet performance through continuous analysis of operational metrics and trends.

- Equipment utilization insights help optimize resource allocation and identify areas for productivity improvement.

advanced fleet tracking installations

advanced fleet tracking installations- Predictive maintenance strategies reduce downtime, extend equipment lifespan, and optimize resource allocation.

- Automated compliance tracking ensures adherence to safety regulations and streamlines reporting processes.

Real-Time Location Tracking

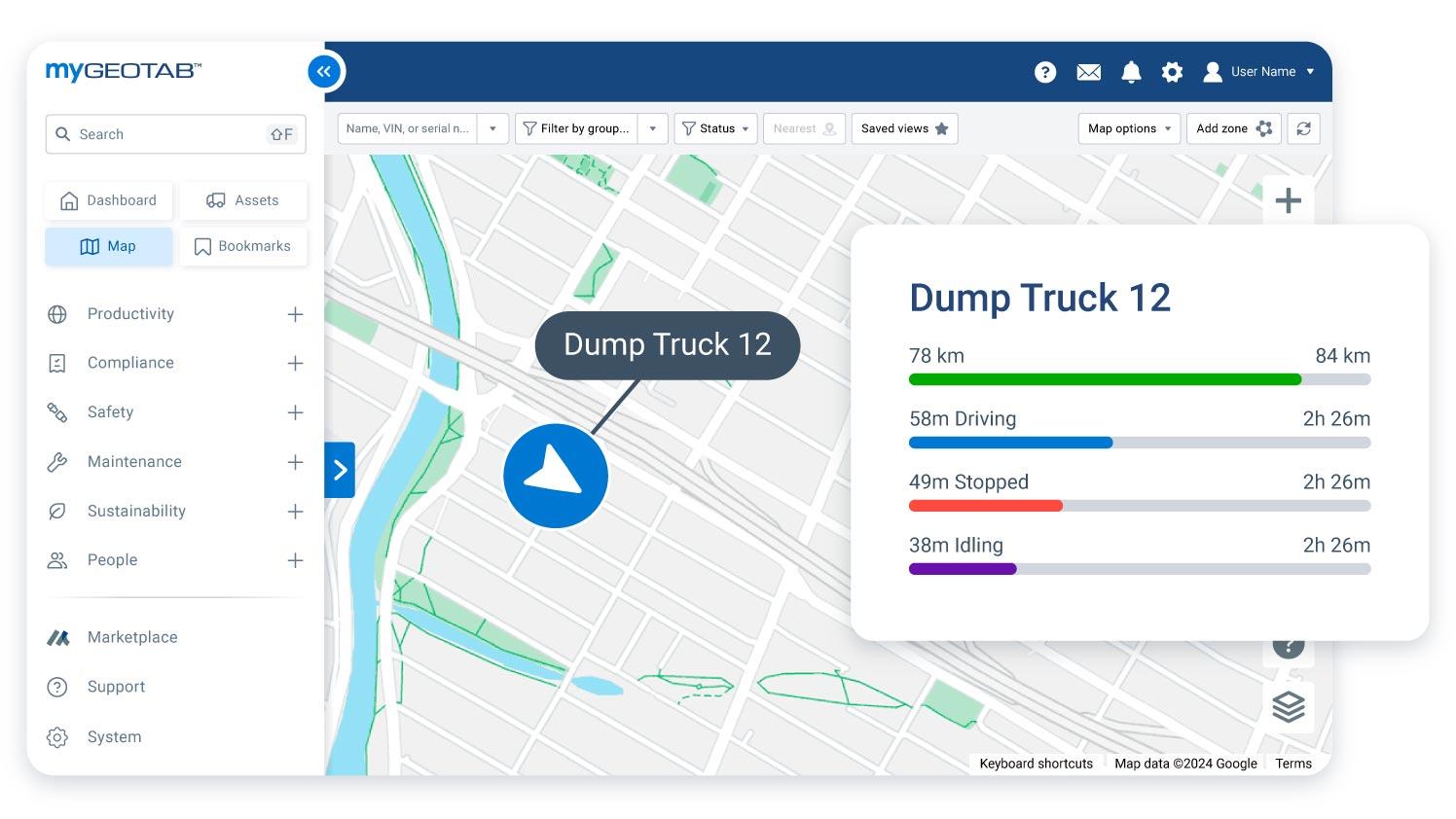

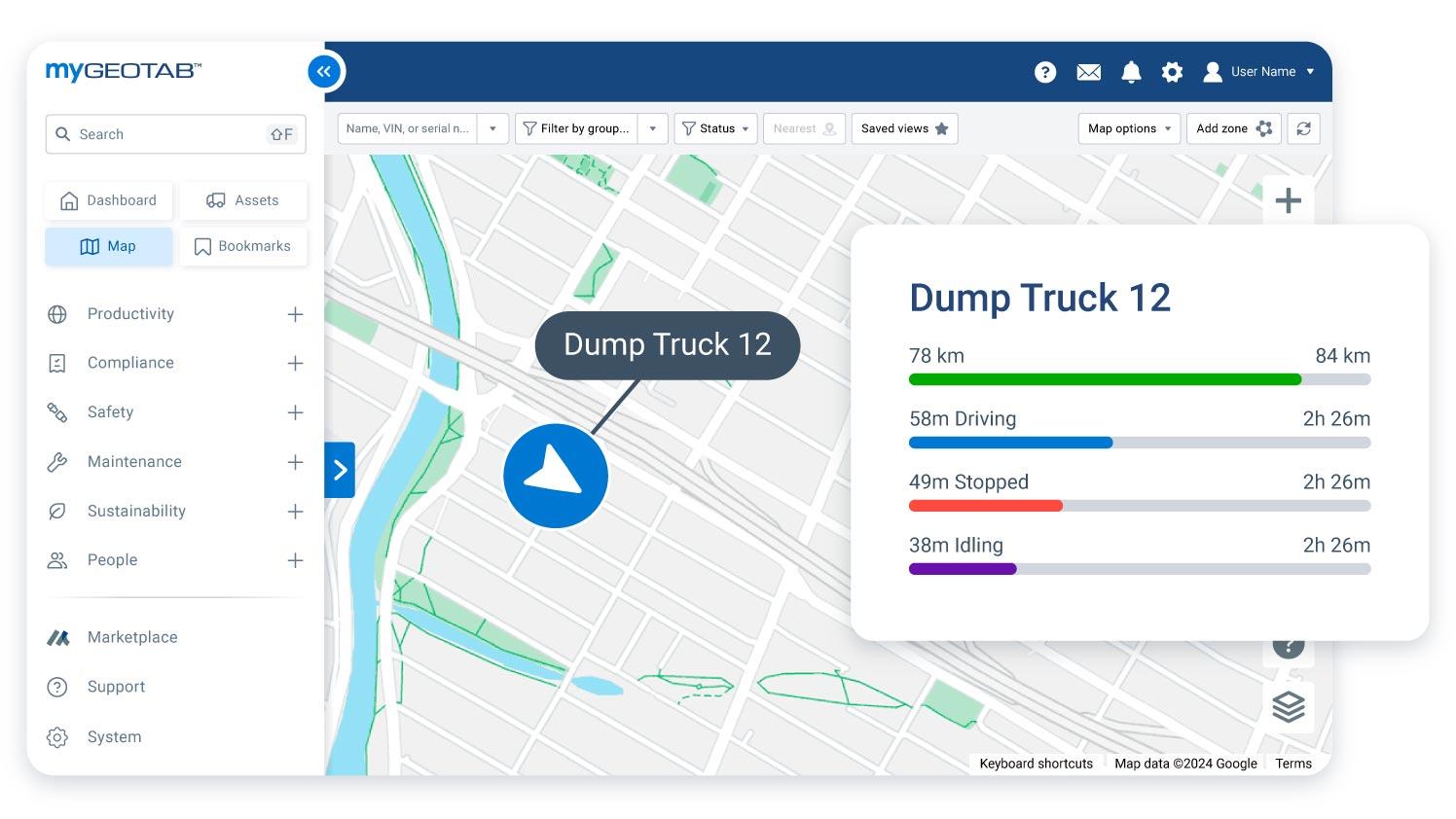

Three key technologies enable real-time location tracking for construction fleets: GPS. advanced fleet tracking installations, RFID, and cellular triangulation. These geolocation technologies form the backbone of modern asset tracking systems, allowing you to monitor your equipment's precise location at any given moment

GPS provides global coverage and high accuracy, ideal for tracking large machinery across expansive job sites. RFID offers localized tracking within confined areas, perfect for tool and material management in warehouses or staging areas. Cellular triangulation utilizes existing mobile networks, providing a cost-effective solution for urban environments.

By implementing real-time location tracking, you'll enhance operational efficiency and safety - advanced fleet tracking installations. You can optimize route planning, reducing fuel consumption and minimizing idle time. The system allows for quick response to emergencies, enabling you to dispatch the nearest available equipment or personnel

Asset tracking also deters theft and unauthorized use (advanced fleet tracking installations). You'll receive instant alerts if equipment leaves designated areas, allowing for swift recovery. This technology integrates seamlessly with maintenance schedules, ensuring timely servicing based on actual usage rather than arbitrary timeframes

Ultimately, real-time location tracking enables you to make data-driven decisions, streamline operations, and maintain a safer, more productive construction fleet.

Equipment Utilization Insights

Real-time location data forms the foundation for deeper equipment utilization understanding. By analyzing this data, you'll gain vital perspectives into your fleet's performance and efficiency. Equipment utilization metrics. advanced fleet tracking installations provide an all-encompassing view of how effectively you're using your assets, allowing you to optimize operations and reduce costs

With real-time data, you can: (construction equipment fleet monitoring)

construction equipment fleet monitoring

construction equipment fleet monitoring- Monitor idle time vs. active use

- Identify underutilized equipment

- Track equipment performance across job sites

- Assess machine productivity rates

- Compare actual usage to planned schedules

These perspectives enable you to make data-driven decisions about fleet allocation, maintenance scheduling, and equipment replacement (advanced fleet tracking installations). You'll be able to pinpoint inefficiencies and address them promptly, ensuring your fleet operates at peak performance

Predictive Maintenance Strategies

Predictive maintenance strategies utilize real-time data (advanced fleet tracking installations) to anticipate equipment failures before they occur. You'll reduce downtime and extend machinery lifespan by implementing proactive equipment repairs based on sensor data and usage patterns. Optimizing maintenance schedules through data-driven observations guarantees your fleet operates at peak efficiency, minimizing unexpected breakdowns and maximizing productivity on construction sites

Proactive Equipment Repairs

Construction companies can slash downtime and enhance efficiency by implementing proactive equipment repair strategies. By harnessing real-time data and remote diagnostics, you'll be able to anticipate potential issues before they escalate into costly breakdowns. This approach not only extends equipment lifecycles but also guarantees a safer work environment for your crew.

To implement proactive equipment repairs effectively, consider these key strategies: - advanced fleet tracking installations

- Employ IoT sensors for continuous equipment monitoring

- Implement machine learning algorithms to predict failure points

- Establish a centralized data dashboard for real-time observations

- Develop a tiered maintenance schedule based on equipment criticality

- Create a digital twin of your fleet for thorough analysis

Optimizing Maintenance Schedules

Building on the foundation of proactive equipment repairs, enhancing maintenance schedules through predictive strategies takes fleet management to the next level. By leveraging real-time data, you'll shift from reactive to preventive maintenance, greatly reducing downtime and extending equipment lifespan.

Implement advanced maintenance software (advanced fleet tracking installations) to analyze historical data, usage patterns, and equipment performance metrics. This data-driven approach enables you to predict when maintenance is needed, allowing you to schedule interventions before failures occur. You'll improve resource allocation, minimizing unnecessary maintenance while ensuring critical tasks aren't overlooked

Real-time monitoring of equipment health indicators, such as oil pressure, temperature, and vibration levels, provides instant perspectives into potential issues. By setting predefined thresholds, you'll receive alerts when parameters deviate from normal ranges, allowing for immediate action.

Integrate maintenance schedules with project timelines. advanced fleet tracking installations to minimize disruptions. You'll identify ideal windows for maintenance activities, balancing equipment availability with project demands. This synchronization enhances overall fleet efficiency and productivity

Fuel Consumption Optimization

improving construction fleet performance

improving construction fleet performanceWhile fuel costs continue to be a considerable expense for construction fleets, real-time data analytics offers powerful solutions for optimization. By implementing fuel management systems and leveraging real-time data, you can markedly reduce fuel consumption and associated costs. These systems provide beneficial observations into your fleet's fuel efficiency techniques, allowing you to make data-driven decisions to improve overall performance.

Real-time data enables you to: - advanced fleet tracking installations (explore this service)

- Monitor fuel consumption patterns across your fleet

- Identify inefficient driving behaviors and address them promptly

- Optimize route planning to reduce unnecessary mileage

- Track idling time and implement strategies to minimize it

- Detect potential fuel theft or unauthorized use

how to track construction fleets

how to track construction fleetsSafety and Compliance Monitoring

Real-time incident reporting and compliance tracking automation are essential components of safety and compliance monitoring in construction fleet operations. You'll enhance your ability to respond swiftly to accidents or near-misses by implementing systems that instantly alert supervisors and safety teams. Automated compliance tracking guarantees you're always up-to-date with regulatory requirements, reducing the risk of violations and associated penalties.

Real-Time Incident Reporting

Construction sites' safety and compliance monitoring take a quantum leap forward with real-time incident reporting systems. These advanced tools enable you to instantly capture, analyze, and communicate critical safety information across your fleet operations - advanced fleet tracking installations. By leveraging incident analysis tools, you'll gain immediate observations into potential hazards, allowing for swift corrective actions and preventing future occurrences

Implement strong incident communication strategies to guarantee all stakeholders are promptly informed and can respond effectively. Real-time incident reporting offers numerous benefits:

- Rapid response to emergencies

- Improved accuracy in incident documentation

- Enhanced visibility of safety trends

- Streamlined compliance reporting

- Reduced downtime and associated costs

You'll experience a significant reduction in incident response times, minimizing the impact on your operations and workforce. By capturing detailed incident data in real-time, you'll build a thorough safety database. advanced fleet tracking installations, enabling data-driven decision-making and continuous improvement of your safety protocols

Integrating real-time incident reporting with your existing fleet management systems creates an all-encompassing approach to safety and compliance. This integration allows for automatic alerts, customized reporting, and seamless data flow between different operational areas, maximizing efficiency and guaranteeing a safer work environment for your entire construction fleet.

Compliance Tracking Automation

Automated compliance tracking systems revolutionize safety and regulatory adherence in construction fleet operations (advanced fleet tracking installations). These sophisticated tools continuously monitor your fleet's activities, ensuring real-time compliance with industry standards and regulations. You'll benefit from automatic alerts when vehicles or operators deviate from established safety protocols or fail to meet regulatory requirements

By utilizing data-driven knowledge, you can proactively address potential compliance issues before they escalate. The system maintains thorough audit trails, documenting all safety-related activities and inspections. This careful record-keeping simplifies reporting processes and strengthens your position during regulatory audits.

You'll experience enhanced efficiency as manual compliance checks become obsolete. The automation streamlines safety management, allowing you to allocate resources more effectively. Real-time data on operator certifications, equipment maintenance schedules, and safety training completion rates enables you to make informed decisions quickly.

Compliance tracking automation also facilitates trend analysis - read more, helping you identify recurring safety concerns and implement targeted improvements. By employing this technology, you'll create a safer work environment. advanced fleet tracking installations, reduce liability risks, and demonstrate your commitment to regulatory compliance. Ultimately, this data-driven approach to safety and compliance monitoring will optimize your fleet operations and protect your bottom line

Data-Driven Decision Making

construction equipment fleet monitoring

construction equipment fleet monitoringThree key factors drive successful construction fleet operations: data collection, analysis, and application. advanced fleet tracking installations. By leveraging real-time data analytics, you'll reveal powerful perceptions to enhance operational efficiency and risk management. Data-driven decision making enables you to optimize workforce productivity, improve project forecasting, and achieve significant cost reduction

Integrating advanced technology into your fleet management systems allows for:

- Real-time tracking of equipment utilization

- Predictive maintenance scheduling

- Fuel consumption optimization

- Route optimization for material delivery

- Automated safety compliance monitoring

By utilizing these capabilities, you'll streamline your supply chain optimization efforts and elevate overall performance metrics - advanced fleet tracking installations. The continuous flow of data enables you to make informed decisions quickly, adapting to changing project conditions and minimizing downtime

Effective stakeholder engagement is essential in implementing data-driven strategies. Confirm your team understands the significance of data collection and analysis in improving safety and efficiency. By cultivating a culture of data-driven decision making, you'll create a more responsive and agile construction fleet operation. This approach not only enhances current project outcomes but also provides important perceptions for future planning and resource allocation.

Frequently Asked Questions

How Much Does Implementing Real-Time Data Technology Typically Cost for Construction Fleets?

improving construction fleet performance

improving construction fleet performanceYou'll need to conduct a cost-benefit analysis to determine the exact investment. Technology costs vary widely, but typically range from $500-$2000 per vehicle (advanced fleet tracking installations) - construction fleet tracking. Consider long-term efficiency gains and improved safety when evaluating this technology investment

What Level of Technical Expertise Is Required to Manage Real-Time Data Systems?

You'll need data literacy and software training to manage real-time systems effectively. Invest in your team's technical skills, from basic data analysis to advanced software operation. Prioritize ongoing education to guarantee safe, efficient, and data-driven fleet management.

Can Real-Time Data Integration Improve Project Bidding Accuracy and Competitiveness?

You'll gain a competitive advantage with data-driven bidding. Real-time data integration enhances your project cost estimates, resource allocation, and risk assessment. advanced fleet tracking installations. This precision improves bidding accuracy, ensuring safer, more efficient operations while increasing your chances of winning contracts

How Does Weather Data Impact Real-Time Construction Fleet Management Decisions?

With 35% of construction delays caused by weather, you'll find that accurate weather data greatly impacts fleet management decisions. You'll enhance data accuracy, optimize operations, and improve safety by integrating real-time weather information into your decision-making process.

Are There Privacy Concerns With Collecting Real-Time Data From Construction Equipment Operators?

You'll face privacy concerns when collecting real-time data from operators. Guarantee data security measures are in place and obtain operator consent. Implement strict protocols to protect sensitive information while maximizing efficiency and safety in your construction fleet operations.

Conclusion

You've seen how real-time data can revolutionize your construction fleet operations. By utilizing these technologies, you'll increase efficiency, reduce costs, and enhance safety. Did you know that construction companies using real-time data analytics report a 21% rise in equipment utilization? It's time to tap into this power. Implement these data-driven strategies now to optimize your fleet - advanced fleet tracking installations, stay competitive, and drive your business forward in today's fast-paced construction industry