In the jewelry industry, precision is key. From crafting delicate gold rings to designing intricate pendants, maintaining consistent quality is a challenge for jewelers. One tool that has proven invaluable in ensuring this consistency is the Thickness Gauge Meter. This essential device allows jewelers to measure the thickness of materials with pinpoint accuracy, helping them maintain high standards of craftsmanship. In this blog, we will explore how a thickness gauge meter helps jewelers maintain consistent quality and why WJT India Pvt Ltd is a trusted provider of this critical tool.

The Importance of Consistency in Jewelry Making

Jewelry is an art that requires a blend of creativity and precision. Whether it's a simple pair of earrings or an ornate necklace, the quality of the jewelry hinges on several factors, including design, materials, and craftsmanship. However, one of the most important yet overlooked aspects of jewelry making is the consistent thickness of the materials used.

Inconsistent thickness can lead to various problems, such as:

-

Uneven weight distribution, affecting the balance and comfort of the jewelry piece

-

Structural weaknesses, making the jewelry prone to breakage or wear

-

Poor aesthetic quality, which could make the jewelry look unpolished or amateurish

By using a thickness gauge meter, jewelers can ensure that each component of their designs is uniform, maintaining a high level of quality across all their creations.

How a Thickness Gauge Meter Works

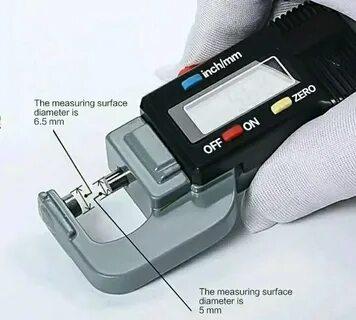

A thickness gauge meter is a device designed to measure the thickness of materials. In jewelry making, this typically refers to metals like gold, silver, platinum, and even more exotic materials like titanium or palladium. Thickness gauge meters come in various forms, including manual and digital versions, each designed to provide accurate and reliable measurements.

The working principle of a thickness gauge meter is simple:

-

The jeweler places the jewelry material between the sensor or probes of the gauge.

-

The device then measures the distance between the probes, providing a precise thickness reading.

-

The reading helps jewelers determine if the material is consistent and meets the required specifications for their design.

WJT India Pvt Ltd provides advanced thickness gauge meters that are easy to use and deliver accurate readings, ensuring that jewelers can quickly and efficiently assess the quality of their materials.

Enhancing Quality Control with a Thickness Gauge Meter

Maintaining consistent quality is a key priority for jewelers, and a thickness gauge meter plays an essential role in achieving this. Here's how this tool helps enhance quality control:

1. Ensuring Uniformity in Materials

Whether working with metal sheets, wires, or other components, jewelers must ensure that each piece is of uniform thickness. Variations in thickness can result in imbalances that affect both the appearance and durability of the jewelry. By using a thickness gauge meter, jewelers can measure the thickness of their materials at multiple points to ensure consistency.

2. Improving Structural Integrity

Jewelry is often worn daily, which means it needs to be durable enough to withstand constant use. Uneven thickness can lead to weak spots, making the piece more susceptible to breaking or bending. With a thickness gauge meter, jewelers can detect these inconsistencies early in the production process and make adjustments before completing the piece, ensuring that the final product is both beautiful and durable.

3. Meeting Design Specifications

In custom jewelry design, meeting the client’s specifications is crucial. Clients expect their jewelry to be crafted with precision, including having materials that meet specific thickness requirements. By using a thickness gauge meter, jewelers can ensure that their creations meet exact specifications, helping to build trust and satisfaction among their customers.

4. Reducing Material Waste

Working with precious metals like gold and platinum is expensive, and every millimeter of material counts. A thickness gauge meter helps jewelers minimize waste by allowing them to cut and shape materials more precisely. With accurate thickness measurements, jewelers can avoid unnecessary mistakes that lead to material waste, ultimately saving both time and money.

5. Boosting Production Efficiency

Consistency in thickness not only improves the quality of the final product but also speeds up production. By using a thickness gauge meter, jewelers can quickly verify that their materials meet the required standards, reducing the need for rework and adjustments. This streamlines the production process and allows jewelers to complete their projects more efficiently.

Why Choose WJT India Pvt Ltd for Your Thickness Gauge Meter Needs

WJT India Pvt Ltd is a leading provider of high-quality thickness gauge meters that are ideal for use in the jewelry industry. With a focus on precision, durability, and ease of use, WJT India’s thickness gauge meters help jewelers maintain the consistent quality needed to produce stunning, high-end jewelry pieces.

Key Features of WJT India Pvt Ltd’s Thickness Gauge Meters:

-

High Precision: Accurate readings ensure that jewelers can achieve consistent thickness in their designs.

-

Durability: Built to last, these devices are designed to withstand the demands of daily use in a busy jewelry workshop.

-

User-Friendly Interface: Digital models offer easy-to-read displays and simple operation, making them accessible even for beginners.

-

Versatility: Suitable for measuring various materials, from precious metals to gemstones.

Conclusion

For jewelers, maintaining consistent quality is essential to success, and a thickness gauge meter is a vital tool in achieving this goal. By ensuring uniformity in materials, enhancing structural integrity, and improving production efficiency, a thickness gauge meter can help jewelers create high-quality, durable, and aesthetically pleasing pieces. WJT India Pvt Ltd offers top-tier thickness gauge meters that are trusted by professionals in the jewelry industry to ensure precision and reliability in every measurement.