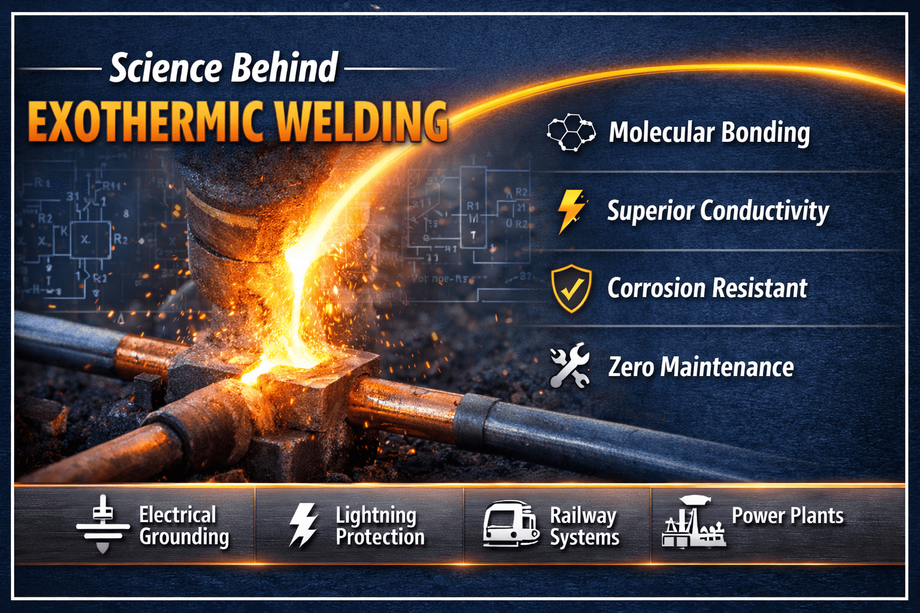

Understanding the Science Behind Exothermic Welding helps engineers, contractors, and electrical professionals appreciate why this technique is considered one of the most reliable methods for permanent electrical connections. Exothermic welding is widely used in grounding, bonding, lightning protection, and power distribution systems due to its unmatched durability and conductivity.

This article explains the scientific principles, chemical reactions, and real-world benefits that make exothermic welding superior to mechanical and compression connections.

What Is Exothermic Welding?

Exothermic welding is a metallurgical joining process that uses a high-temperature chemical reaction to fuse conductors together. Unlike traditional welding methods, it does not require an external power source, making it ideal for remote and harsh environments.

At the core of this process lies the Science Behind Exothermic Welding, which is based on controlled chemical energy rather than electrical or mechanical force.

The Chemical Reaction Explained (Aluminothermic Reaction)

The fundamental Science Behind Exothermic Welding involves an aluminothermic reaction between metal oxides and aluminum powder.

Key Scientific Steps:

-

Copper oxide reacts with aluminum

-

The reaction releases extreme heat (approximately 2,500°C)

-

Molten copper is produced

-

The molten metal flows into a graphite mold

-

A solid, molecular-level bond is formed after cooling

This reaction is self-sustaining once ignited and ensures complete fusion between conductors.

Role of Graphite Molds in Exothermic Welding

Graphite molds play a critical role in the Science Behind Exothermic Welding. These molds:

-

Withstand extremely high temperatures

-

Shape the molten metal accurately

-

Ensure consistent and repeatable weld quality

-

Prevent contamination during the bonding process

The mold design directly affects the strength, conductivity, and finish of the final connection.

Molecular Bonding: The Real Advantage

One of the biggest advantages explained by the Science Behind Exothermic Welding is molecular bonding. Instead of clamping or pressing metals together, exothermic welding:

-

Creates a homogeneous metal joint

-

Eliminates contact resistance

-

Prevents loosening over time

-

Resists corrosion and oxidation

This makes the joint electrically and mechanically stronger than the original conductor.

Why Exothermic Welds Offer Superior Conductivity

According to the Science Behind Exothermic Welding, conductivity improves because:

-

There is no interface resistance

-

The weld becomes a single continuous conductor

-

Electrical current flows without interruption

This is especially critical for grounding and lightning protection systems where low resistance is essential for safety.

Temperature, Strength, and Durability

The extreme heat generated during the process:

-

Ensures complete fusion of metals

-

Produces joints that can withstand thermal cycling

-

Provides resistance against vibration and environmental stress

From a scientific perspective, the Science Behind Exothermic Welding ensures long-term reliability even in underground, coastal, or industrial environments.

Applications Based on Scientific Reliability

Because of the proven Science Behind Exothermic Welding, this method is widely used in:

-

Earthing and grounding systems

-

Power substations

-

Railway electrification

-

Telecommunication towers

-

Lightning protection networks

These applications demand permanent, maintenance-free connections supported by scientific consistency.

Conclusion

The Science Behind Exothermic Welding explains why this process is trusted worldwide for critical electrical connections. By combining chemical energy, extreme heat, and molecular bonding, exothermic welding delivers unmatched conductivity, corrosion resistance, and mechanical strength.