EV Thermal Management: Get the Odds in your favor!

The adoption of Electric Vehicles (EV) is growing rapidly across the globe, a study estimates an annual growth rate of 8% by 2025. One of the drivers being lower cost with improved EV battery technology. Currently, 65% of the total EV cost is contributed by the battery, with the technology used predominantly being Lithium-ion due to high energy density and smaller size.

A key challenge with Lithium-ion batteries is the safe operation at higher temperatures and acceptable performance at lower temperatures. Automotive OEM’s across the globe are developing sophisticated battery thermal management techniques for safe and optimum battery performance. The higher the EV performance and safer it is compared to internal combustion vehicles, the faster it will drive the consumer adoption.

The fiber optic sensor is becoming the industry standard for battery pack testing. Several leading OEM’s have realized the inherent advantage of using fiber optic temperature sensors over K type thermocouples and have already implemented this technology in their battery validation or testing process.

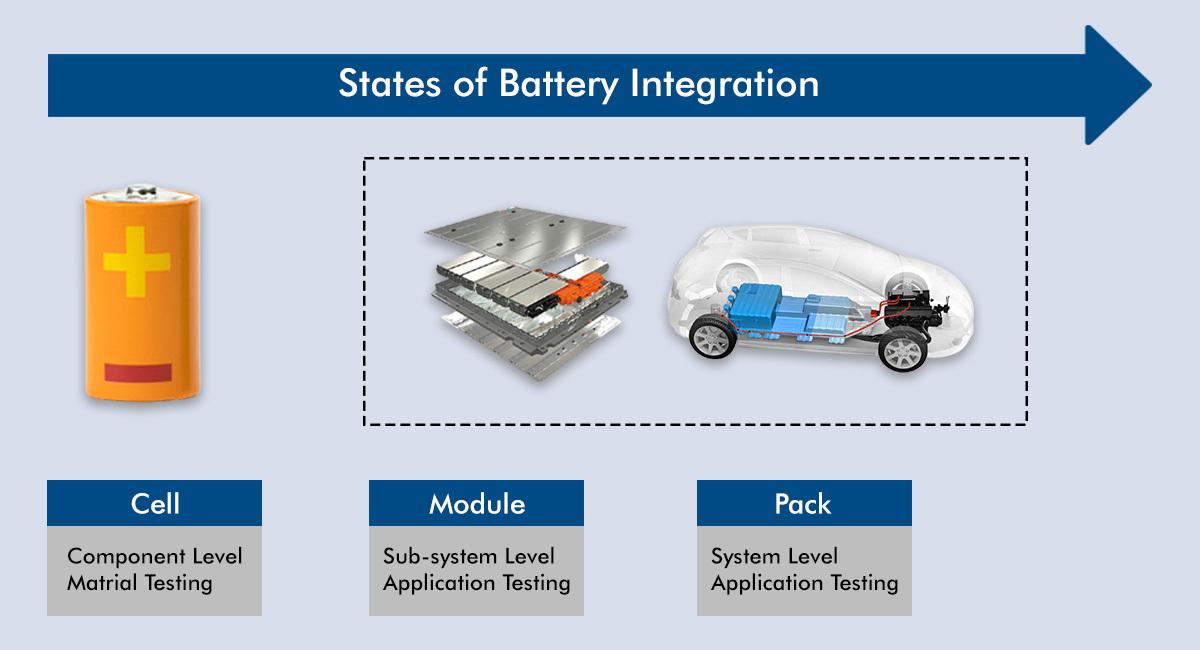

Structure of an EV battery

The typical structure of any EV battery consists of a cell, module, and a pack. At a very simplistic level, a module is a collection of cells in a specific arrangement and a pack is a collection of modules in a specific arrangement. Each pack has Battery Management System (BMS) which has proprietary algorithms that collects and analyses data using sensors to make decisions for safe operation.