The Essential companion to Electrical Metal Stamping Parts

As technology continues to advance, there’s also an adding need for high- quality and effective electrical factors to keep up with the advancements. As an illustration of a element that plays an important part in numerous electrical bias, essence stamping corridor are one of those factors. In addition to their use in a wide variety of operations, these corridor are also used in complex ministry used in the manufacturing process, as well as in simple ménage appliances. This companion aims to give you with an overview of the essential companion to electrical essence stamping corridor, similar aluminum stamping as what they are, how they work, and the colorful operations for which they can be used.

What are Electrical Essence Stamping corridor?

As essence stampedings are also known as electrical essence stamping corridor, electrical essence stampings are factors that are made by shaping and cutting essence wastes into specific shapes and sizes using essence stamping machines. corridor like these are used in a wide range of operations ranging from electrical enclosures to automotive factors, for illustration. The essence stampings can be made from a wide variety of essence, including aluminum, bobby , and sword, and can be made via a variety of styles, including progressive stamping and deep delineation, among others.

The Essence Stamping Process

Essence stamping is a process that involves a number of way, including designing, creating tools, stamping, and finishing essence corridor. A stamping part begins with the design process, in which masterminds and contrivers work together in order to produce a design for the part that’s to be stamped. There’s a lot of information included in this design, including information about the asked shape, size, and material of the element.

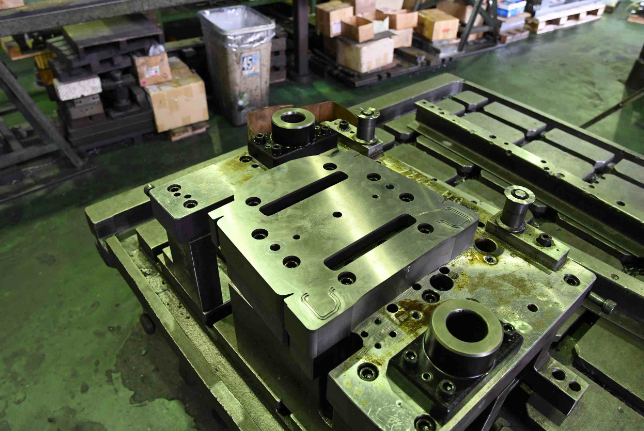

Following the finalization of the design, the tooling process will begin as soon as the design is complete. Tooling is the process of creating the dies and molds that will be used to form the essence into the shape that’s asked using the dies and molds. Tools like these are stamping parts company generally made from hardened sword and are generally veritably precious, especially when it comes to complex stamped corridor that bear a lot of perfection.

As soon as the tooling has been completed, the stamping process can begin. As part of this process, essence wastes need to be fed into a stamping press, where the dies and molds are used to shape the essence into the asked shape. Stamping can be done using any number of ways, including progressive stamping, deep delineation, and a variety of other styles.

Eventually, the final stage of the finishing process involves cleaning and polishing the essence stamping part so that any sharp edges or churrs that may have been created by the stamping process are removed.

operations of Electrical Metal Stamping Parts

Electrical essence stamping corridor have a wide range of operations across numerous different diligence. Some of the most common operations include

Electrical Closes

Essence stamping corridor are frequently used to produce electrical enclosures, which cover electrical outfit from damage and give a safe working terrain for technicians. These enclosures can be made from a variety of essence, including aluminum and sword, and can be designed to meet specific size and shape conditions.

Metal stamping corridor are also generally used in the automotive assiduity to produce a wide range of factors, including body panels, classes, and machine corridor. These corridor are generally made from high- strength accoutrements , similar as sword and aluminum, and are designed to meet strict performance and safety norms.