In an era defined by precision, accuracy, and quality, industries across the globe continually explore ways to enhance their production capabilities. Recently, the role of white light interferometry objective lenses in manufacturing has gained considerable traction, thanks to the increasing emphasis on stringent quality control processes. Let's delve into how these sophisticated lenses are reshaping manufacturing and why they are essential in today's quality-driven market.

The Shift Towards Enhanced Quality Control

Traditionally, the manufacturing industry has relied on established practices to ensure product consistency and quality. However, given today's competitive landscape and heightened consumer expectations, businesses are compelled to push the boundaries of innovation. The resultant paradigm shift prioritizes advanced quality control methodologies.

This push is driven primarily by:

-

Increased Product Complexity: With the surge in technological advancements, products now boast intricate designs and functionalities, demanding an equivalent sophistication level in manufacturing processes.

-

Stringent Regulatory Standards: Global standards for quality and safety continue to evolve. From electronics to automotive sectors, the demand for precision is non-negotiable.

-

Consumer Expectations: Informed and discerning consumers expect high-quality, defect-free products, prompting manufacturers to employ the best tools and technologies.

The Role of White Light Interferometry Objective Lenses

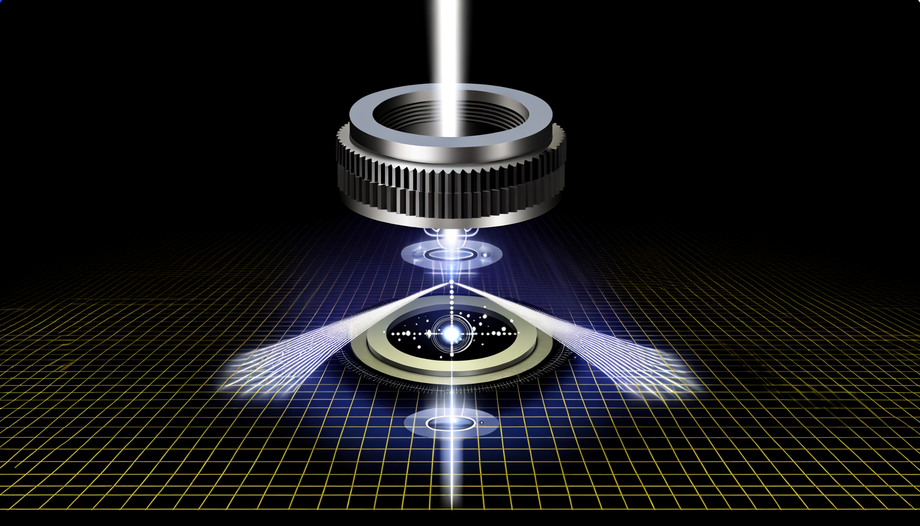

Enter White Light Interferometry (WLI) – a non-destructive optical technique that stands out for its precision and accuracy. At the heart of this technique are objective lenses designed to resolve minute details, aiding manufacturers in achieving unprecedented levels of quality.

How It Works:

White Light Interferometry employs a broadband light source to create interference patterns which, when analyzed, produce high-resolution 3D surface maps. These maps are crucial for:

- Identifying surface imperfections.

- Measuring layer thicknesses.

- Evaluating product uniformity and thickness variations.

Why Objective Lenses Matter:

The power of WLI lies predominantly in its objective lenses. These lenses offer:

- High Optical Resolution: Capturing intricate surface details to detect micro-level imperfections.

- Enhanced Depth Range: Allowing reliable mapping of surfaces that traditional counterparts may falter with.

- Superior Reproducibility: Ensuring consistent results across various measurements.

Real-World Applications

Objective lenses designed for white light interferometry are increasingly becoming a staple in various industries thanks to their precision and versatility.

Automotive Industry:

Quality control is pivotal in the automotive sector. With cars boasting advanced features and safety protocols, ensuring every component is flawless has never been more crucial.

- Benefits:

- Detects micro-scratches and defects on engine parts.

- Ensures uniformity in the coating process.

Semiconductor Manufacturing:

Semiconductors are the building blocks of modern electronics. Their production demands immaculate precision, which makes WLI indispensable.

- Benefits:

- Monitors wafer surface quality with extreme accuracy.

- Measures step heights critical in circuit design.

Medical Device Fabrication:

Medical devices must comply with stringent health and safety standards. Thus, precision in component manufacturing is essential for efficacy and user safety.

- Benefits:

- Ensures flawless surface finishings on medical implants.

- Validates dimensions and tolerances of intricate device components.

The Road Ahead

White Light Interferometry and its associated lens technology represent not only the present but also the future of manufacturing quality control. As industries continue to grapple with challenges about product quality, these tools will evolve.

-

Technological Advancements: Expect lenses with better resolution capabilities and enhanced material compatibility.

-

AI and Machine Learning Integration: Artificial intelligence will drive improved defect recognition, leading to faster and more reliable analysis.

-

Cost Reduction and Efficiency: As technology becomes more widespread, economies of scale will decrease costs, making them accessible to a wider range of manufacturers.

In conclusion, the increased emphasis on quality control in manufacturing is seamlessly intertwining with the innovation of white light interferometry objective lenses. For manufacturers aiming to stay ahead in an ever-competitive industry, embracing such technology is not just advisable—it's essential.

Explore Comprehensive Market Analysis of White Light Interferometry Objective Lenses Market

SOURCE -- @360iResearch