Re-Inking Used Printer Ribbons

From: Chuck Darling

February 12, 2025

Re: The Re-Inker

Back in the early 1990's,

the company I worked for

used Okidata Dot-Matrix Printers

that used Red/Black cartridges

that cost 18 dollars each...

They cost $62 dollars now...

We used six per week...

I found a Re-Inker machine

advertised in computer industry

periodicals.

The Re-Inker had a spindle, specially

ordered to fit the Okidata ribbons.

It would drive the ribbon at about

one inch per second, past a tubular

ink reservoir that had a pinhole

on the side.

You could adjust the reservoir height

to re-ink the ribbon where it was worn.

This worked out fine for the large red/black

ribbon cartridges, re-inking only the black.

Once I got it going, we saved on

four cartridges per week.

Four cartridges @$18 = $72 dollars/week.

52 week operation saved $3744 annually.

That would save $12,896 per year today...

Not bad.

Small black ribbons can be pulled out

in a Ziplock bag, and sprayed with

WD-40. Wear gloves.

If you want to build a reliable automatic

Jig, use an old phono turntable

with a (3D printed) sprocket

to drive the ribbon. Put a well below

the ink supply, to catch and re-use

ink drops.

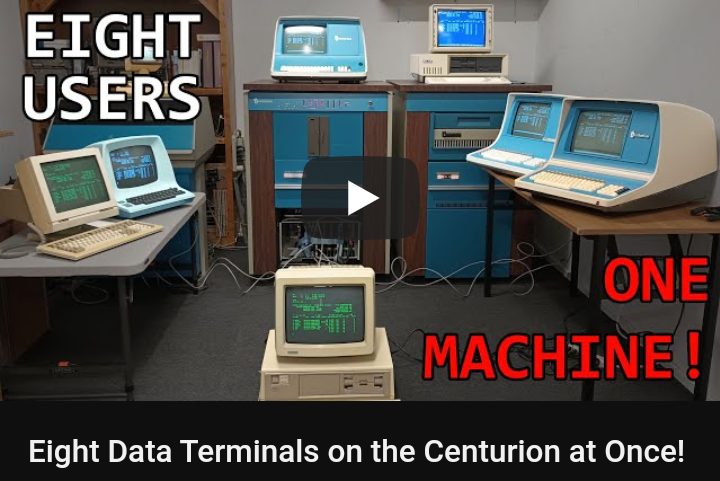

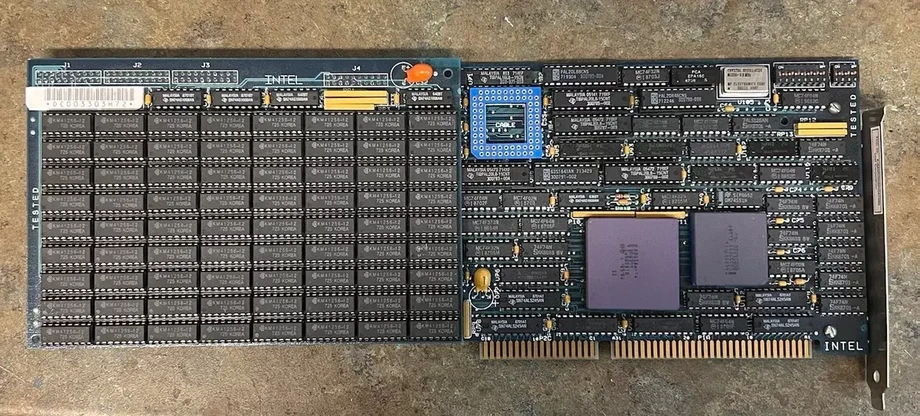

Back in 1990, we used several IBM AT/286

machines, with the brand-new (beta test)

Intel Inboard 386.

That and a couple multiport serial cards,

and our machine could handle 12 users

on Wyse Terminals, or PC's. Cacheing

Controllers for multiple Hard Drives, and

a custom print-spooler program kept

two OKI 2410's very busy.

Multiuser Multi-tasking Dos ...

[Chuck's 00Cedar JPICedar ]

[ This page built with JPICedar by Chuck Darling Tuesday Feb-12-2025 Time : 9:11a]