Businesses carry different types of inventory. Even the industries that focus on production rather than warehousing keep track of supplies. Accordingly, businesses and fulfillment centers require some systems to track their stock. An inventory system is a methodology that companies use to keep track of everything they stock.

Business facilities often employ one or two types of inventory systems, namely periodic and perpetual. Technological demands and the complications of implementation increase as a facility moves from regular to the perpetual inventory system, while accuracy and efficiency improve.

Do not confuse the term inventory system with an inventory management system, as the former entails tracking inventory while the latter involves the techniques used to support the former. The inventory management system includes multiple technologies such as barcodes, software, and RFID tags used by fulfillment centers such as Imagine Supply Chain.

Periodic Inventory System

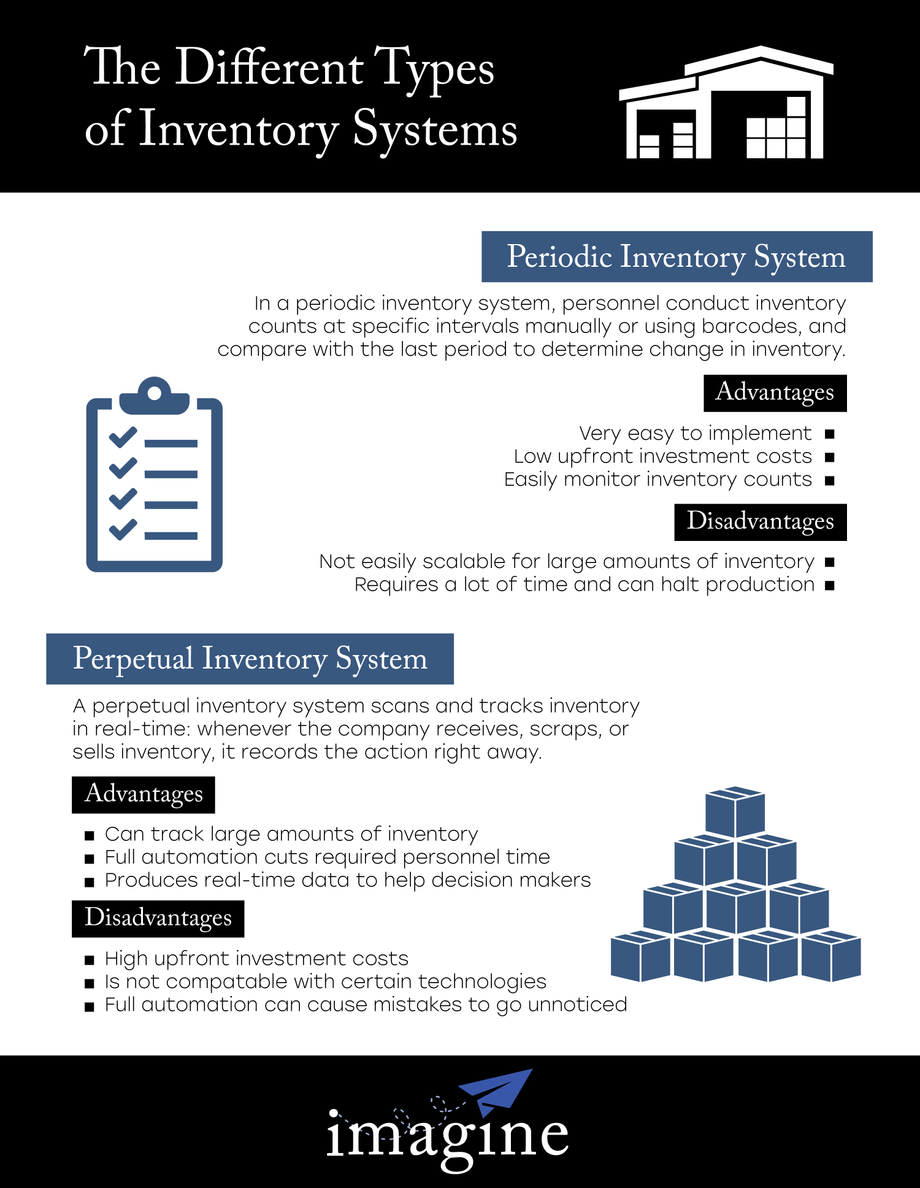

A periodic inventory system uses physical counting periodically. As a result, it highly depends on either barcode coupled with scanners or manual counting with checklists. Many businesses incorporate automation into their periodic inventory systems. Scanners and barcodes enable them to bypass manually updated spreadsheets, making regular counts more tolerable and less labor-intensive.

What Happens in a Periodic Inventory System?

Personnel does physical counts of inventory items at specific intervals, which can be after three months, six months, or annually. They record the quantity of each item, either automatically in a database, spreadsheet, or manually. They compare the registered number with the counts from the last period to establish the change in inventory.

Advantages of Periodic Inventory Systems

- Periodic inventory systems are easy to implement as they comprise a physical count of inventory items at set intervals solely.

- It saves upfront costs

- The use of modern technologies such as RFID tags and barcodes is making the periodic inventory system faster.

- Periodic inventory systems allow one to monitor the inventory counts easily, as keeping an eye on the inventory counts is necessary even in fully automated systems.

Disadvantages of Periodic Inventory Systems

- The use of periodic inventory systems may not be possible in larger operations that require hundreds of thousands of items to be processed daily

- Labor that is involved in the periodic inventory system can paralyze the production as personnel invest much time that could be used elsewhere

Perpetual Inventory System

This sophisticated inventory system delivers real-time data in the central system as inventory enters a facility, moves, is sold, used, or discarded.

What Happens in a Perpetual Inventory System?

Whenever the company receives, relocates, uses, scraps, or sells an inventory, it scans it in real-time into a centralized computer system. The scans can either be done manually with barcode scanners or automatically with RFID tags.

Advantages of Perpetual Inventory Systems

- Preferred for most large-scale applications as they offer consistently real-time information on inventory counts and cost of goods sold.

- Fully automating perpetual inventory significantly cuts down on the labor hours required to update the list.

- Since the perpetual inventory system consistently updates data, it can help inform an organization's decision-making as managers and planners receive current and precise data.

Disadvantages of Perpetual Inventory

- High upfront investment cost to run a perpetual inventory system

- It is not feasible without using certain technologies such as inventory management software.

- With a fully automated perpetual inventory system, faults can easily go unnoticed

Getting Started

The two inventory systems have their benefits and drawbacks. However, they can supplement one another to achieve an almost perfect design. For instance, periodic counts would help ensure that data is accurate when using a perpetual inventory system. For more information, companies such as Imagine Supply Chain can help you choose the most appropriate design for your business. Visit http://imaginesupplychain.com/ or call (801) 441-7441 for information about Imagine Supply Chain fulfillment centers in Salt Lake City, Utah.