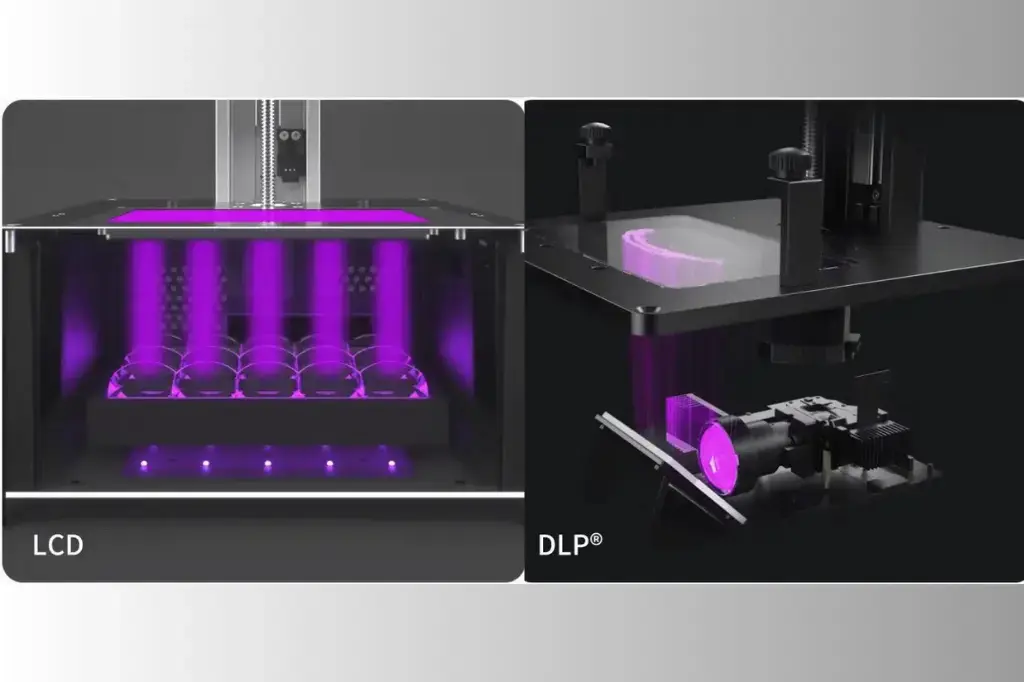

In the realm of 3D printing, LCD and DLP 3D Printers shine as two distinct methods for creating three-dimensional wonders. Each has its own set of strengths and weaknesses, tailored for specific needs. This guide explores both technologies, revealing their pros and cons to help you make an informed choice.

Understanding 3D Printing Basics: 3D printing builds objects layer by layer from a digital design. But what sets LCD and DLP apart? Let's dig in.

Pros and Cons of LCD 3D Printers:

- Pros: LCD printers are speedy, budget-friendly, and precise.

- Cons: They have a shorter LCD lifespan and may display a slight grid pattern on prints.

Pros and Cons of DLP 3D Printers:

- Pros: DLP printers boast high resolution, long-lasting DMD chips, and material versatility.

- Cons: They are slower and typically cost more.

Comparing LCD and DLP:

- Speed: LCD printers are faster; DLP excels in resolution and surface quality.

- Cost: LCD printers are budget-friendly; DLP offers superior quality and durability.

Choosing Between LCD and DLP: Consider your project needs, material compatibility, and budget. LCD suits speed and flexibility, while DLP is best for high detail and precision.

Applications of LCD and DLP: LCD suits jewelry, dental, and prototyping. DLP excels in aerospace, automotive, and medical sectors for high-resolution parts.

In the end, your choice depends on your specific goals. Whether you're a hobbyist, small business owner, or industry professional, understanding LCD and DLP technologies helps you embark on a successful 3D printing journey. Happy printing! to know more click here.