In a world where flexibility and convenience are king, the shift from permanent power connections to detachable cordsets is happening fast. Whether it's consumer electronics, industrial machinery, or medical devices, industries everywhere are moving toward modular power setups. The reasons for this are both practical and future-forward.

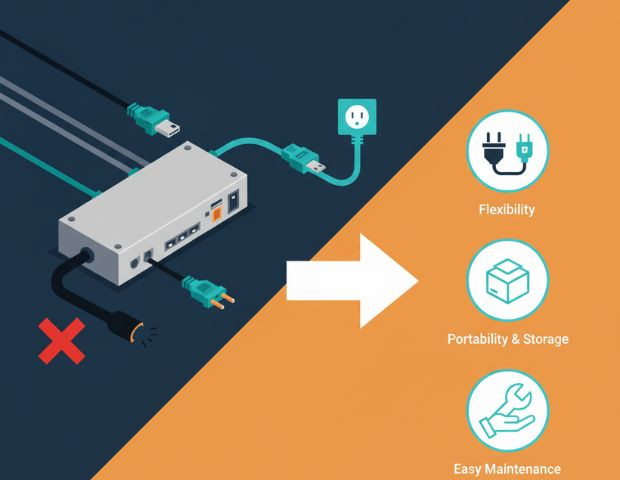

While permanent connections have long been the standard, technology has evolved. More people are now questioning whether permanently wired cords still make sense in an era that values customization, repairability, and ease of transport. Enter the detachable cordset—a simple but powerful innovation that is reshaping the way we think about power delivery.

What Are Detachable Cordsets?

A detachable cordset typically consists of a standardized power cord with a connector at each end—one for the power source and one for the device. This modular approach makes it easy to plug and unplug devices without needing to touch internal wiring. It also simplifies maintenance, shipping, and compliance with regional electrical standards.

By contrast, permanent power connections are hard-wired into the device. They often require a technician to install or replace them, and once they're damaged, the entire unit might need repair or replacement. The lack of flexibility can be a major drawback, especially in fast-moving industries or environments with changing needs.

Demand for Modular Design

One of the biggest drivers behind the shift is the modern demand for modularity. In everything from laptops to lighting systems, users want components that can be easily swapped, upgraded, or repaired. A detachable cordset fits perfectly into this philosophy. Manufacturers, too, benefit from this shift. It allows them to produce one global model of a device and simply include different cordsets depending on the market. This saves costs, reduces production complexity, and supports sustainability by minimizing electronic waste.

Detachable systems also make it easier to meet regional regulations. A product can remain the same across countries, and only the power cord needs to change. That’s much more efficient than building separate models for North America, Europe, or Asia.

Ease of Maintenance and Replacement

Imagine a scenario where a power cord is damaged during shipping or use. With a permanent connection, fixing it may require opening the device, voiding the warranty, or even replacing the entire unit. With a detachable cordset, it's as simple as unplugging the damaged cord and plugging in a new one. This ease of replacement reduces downtime and extends the lifespan of products. It also simplifies inventory and spare parts management, especially for businesses that operate across multiple locations or need to service hundreds of units.

In mission-critical applications—such as hospitals, data centers, or manufacturing lines—time is money. Being able to swap a power cord in seconds rather than hours can have a major impact on operational efficiency.

Improved Safety and Compliance

Safety is another major factor driving the transition. Detachable cordsets are often manufactured to meet stringent international safety standards. They’re UL-listed, CSA-approved, or bear CE markings, depending on the region. This ensures that each component—from the plug to the conductor—is built to perform reliably under stress.

In contrast, permanent connections can sometimes lead to DIY repairs or unsafe workarounds, especially in cases where users try to rewire a damaged cord. This increases the risk of electrical fires, shocks, or short circuits.

Using standardized, replaceable power cords minimizes that risk. And because the cords are designed to meet specific amperage and voltage requirements, the chances of overloading or mismatching are also reduced.

Transport and Storage Advantages

Another overlooked benefit is the logistics side. Devices with fixed cords are bulkier and more difficult to pack. The cords must be coiled or managed during transport, which can lead to bending, wear, or damage. Detachable designs solve this problem. The cord can be packaged separately, making the main device smaller and easier to protect. This is especially beneficial in e-commerce, where shipping efficiency and reduced breakage are top priorities.

Warehousing and distribution have also become easier. Instead of needing separate SKUs for each corded variation of a device, companies can maintain one model and match it with different power cords depending on the customer’s region.

Customization and Branding Opportunities

Brands are always looking for ways to differentiate their products. With detachable cordsets, manufacturers can offer custom lengths, colors, or even branded plugs that reinforce their identity. This is particularly useful in sectors like audio/visual, consumer electronics, or high-end appliances where aesthetics and personalization matter. It gives end-users more control and opens the door for aftermarket accessories and upgrades.

It also benefits OEMs (Original Equipment Manufacturers) who can offer enhanced configurations without changing the core device. Want a longer cord? A retractile option? A coiled version? Just swap it out.

Environmental Sustainability

As global concern for environmental responsibility grows, many companies are looking for ways to extend product life and reduce waste. Detachable cordsets support this by making devices more repairable. Rather than disposing of an entire unit due to a damaged or obsolete power connection, users can simply replace the cord. This modular approach aligns well with right-to-repair movements and sustainability certifications that are increasingly influencing purchasing decisions.

Detachable cords can also be recycled separately, improving recovery rates for valuable materials and reducing the burden on landfills. It’s a small change with a big potential impact.

Standardization in Global Markets

Globalization has made it essential for products to be usable across different regions without complex redesigns. This is where detachable cordsets shine. They allow for a plug-and-play solution to global compatibility. Instead of manufacturing different versions of the same product for each market, brands can produce a single unit and ship it with the appropriate cord for the destination country.

This approach minimizes errors, streamlines logistics, and reduces time to market. It also improves customer satisfaction by ensuring that users receive a product they can immediately use—no adapters or modifications required.

Better Ergonomics and User Experience

Permanent cords often get in the way. They can limit how a device is stored, mounted, or positioned. A detachable cordset, on the other hand, allows for more flexible placement and better cable management. In home and office settings, users appreciate the ability to swap cords to suit their layout. In industrial settings, it improves safety and reduces trip hazards. Wherever the device is used, the experience is cleaner and more intuitive.

From a service and support standpoint, it's also easier for technicians to diagnose issues. If a device fails, isolating the problem is quicker when the power cord can be tested independently.

Future-Proofing and Innovation

The move toward detachable cordsets is part of a larger trend toward modular design in general. As technology advances, the ability to upgrade parts without replacing the whole unit is becoming essential. Having a detachable power connection makes it easier to adopt future technologies—like smart cords with embedded sensors, or cords that integrate with energy monitoring systems. It opens the door to innovation without forcing users to abandon legacy equipment.

For companies focused on R&D, it provides a platform for experimentation. Want to test a new power interface or control module? A detachable system makes it faster and cheaper to prototype.

Cost-Effectiveness Over Time

At first glance, building in a permanent cord might seem cheaper. But when you consider the full lifecycle cost—including service, repairs, logistics, and user satisfaction—detachable cordsets often come out ahead. They reduce the need for technical intervention. They lower shipping and handling costs. They boost product versatility. And they give users the power (literally and figuratively) to control their experience.

Even in environments with strict cost controls, these cumulative benefits make a strong case. It’s not just about saving a few dollars up front. It’s about adding value over time.

FAQs

What is the main advantage of using a detachable cordset over a permanent cord?

A detachable cordset provides flexibility, easy replacement, and compatibility across regions, while permanent cords often require repair or replacement of the entire unit when damaged.

Are detachable cordsets safe for industrial or medical use?

Yes, most detachable cordsets are built to meet strict safety standards like UL, CE, and CSA, making them reliable for sensitive environments such as hospitals and factories.

Do detachable cordsets increase product costs?

While they may have a slightly higher upfront cost, detachable designs often lower total costs over time by reducing maintenance, logistics, and replacement expenses.

Can detachable cordsets support future technologies?

Absolutely. Their modular design makes it easier to integrate emerging features like smart power monitoring, specialized connectors, and sustainable materials without redesigning entire devices.

The rise of detachable cordsets isn’t just a passing trend—it’s a logical evolution in how we design and interact with powered devices. In an age that values efficiency, customization, and sustainability, permanent cords are starting to feel like a relic of the past. Check out High Tech Connections for a variety of solutions tailored to your needs. Contact them via email or by calling (614) 920-0853.