As we stand on the brink of Industry 4.0, the manufacturing landscape is rapidly transforming. Central to this evolution is the undeniable surge in demand for cutting fluid coolers, a pivotal component in industrial machinery production. But what is fueling this demand? And how are manufacturers responding? Let's explore the intricate dynamics underpinning this industrial phenomenon.

Understanding Cutting Fluid Coolers

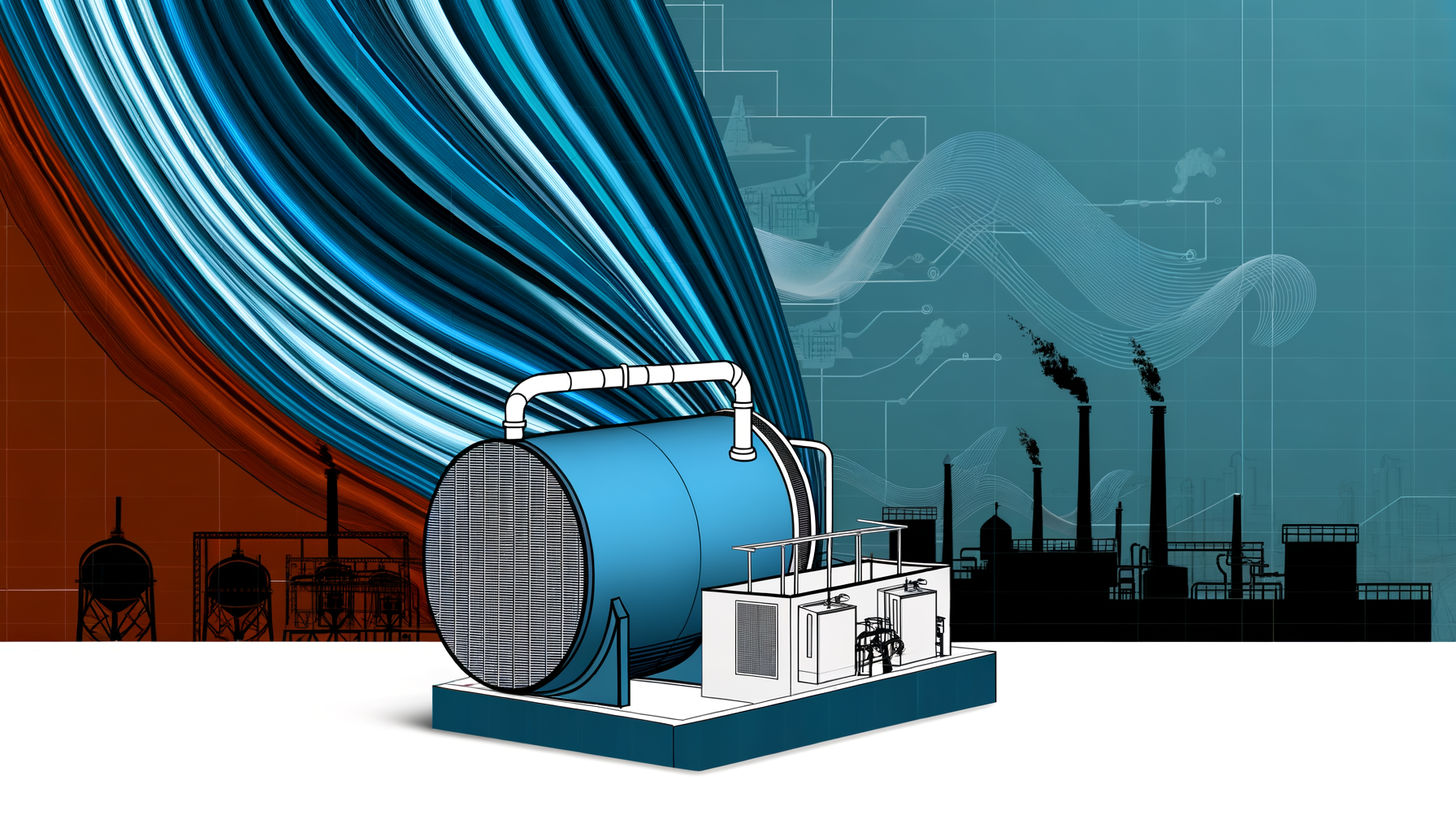

Before delving into the causes of increased demand, it's essential to understand what cutting fluid coolers are and why they are indispensable in the manufacturing sector. Cutting fluid coolers are crucial systems used to maintain the temperature of cutting fluids in machining processes. These fluids play a multi-faceted role, including:

- Lubrication: Reducing friction between cutting tools and workpieces.

- Cooling: Absorbing and dissipating heat generated during machining to prevent tool degradation and workpiece deformation.

- Chip Removal: Aiding in the efficient removal of metal chips from the work area.

Given these capabilities, the cooler's efficiency directly impacts the performance and longevity of industrial machinery.

The Industrial Symbiosis: A Demand Explosion

1. Increased Production of Industrial Machinery

The growing global demand for automation and advanced manufacturing techniques has fueled the production of industrial machinery. With the shift towards high-precision manufacturing, industries from aerospace to automotive require robust, reliable, and efficient machinery. Cutting fluid coolers ensure these machines operate under optimal conditions, boosting productivity and reducing downtime.

2. Technological Advancements

Technological leaps in materials and engineering methods have led to more complex manufacturing processes. In turn, this complexity demands sophisticated cooling solutions to handle higher operational pressures and temperatures. Advanced coolers, equipped with digital controls and real-time monitoring systems, provide precise temperature management, thus matching the pace of technological innovation.

3. Sustainability and Energy Efficiency

The push towards sustainable manufacturing practices has spotlighted energy-efficient cooling solutions. Cutting fluid coolers designed for low-energy consumption not only reduce operational costs but also align with broader environmental goals, making them an attractive option for eco-conscious manufacturers.

4. Emerging Markets and Globalization

Rapid industrialization in emerging economies presents new opportunities for machinery production, further boosting the demand for cutting fluid coolers. As these markets aim to meet international manufacturing standards, investing in superior machinery cooling solutions becomes imperative.

Industry Challenges and Innovations

Despite this booming demand, the industry faces diverse challenges, necessitating innovation:

-

Cost Concerns: Initial investment and maintenance costs for advanced coolers can be high. Manufacturers are experimenting with cost-effective materials and designs without compromising performance.

-

Integration with IoT: The Industrial Internet of Things (IIoT) has transformed many aspects of manufacturing. Cooling systems now need seamless connectivity options to integrate with broader IoT ecosystems, offering data-driven insights and predictive maintenance capabilities.

-

Miniaturization: As machinery designs become more compact, coolers must adapt to offer efficient solutions within smaller footprint constraints.

What's Next?

The trajectory for cutting fluid coolers is suited for sustained growth. With industries prioritizing operational excellence and environmental responsibility, the focus will be on developing coolers that are not only more effective but also smarter and greener. Expect:

-

Enhanced Smart Features: Coolers that utilize AI for auto-optimizing processes.

-

Green Tech Integration: Development of eco-friendly coolants and refrigerants.

-

Custom Solutions: Tailored cooling solutions addressing specific industry challenges.

Conclusion

The rise in demand for cutting fluid coolers signifies more than just a technological shift; it represents a strategic alignment of the manufacturing industry with emerging global aspirations. In this transformative journey, manufacturers who leverage smart, efficient, and sustainable cooling solutions will carve a competitive edge.

As the industrial machinery landscape continues to evolve, so too will the technologies that empower it. Keeping pace with this demand surge, cutting fluid coolers are setting the stage for a future where manufacturing is more precise, sustainable, and intelligent than ever before.

Stay connected with industry trends, technological advancements, and insight-driven content to leverage this exciting era of manufacturing innovation. Join the conversation, because the industrial revolution is not coming—it's here.