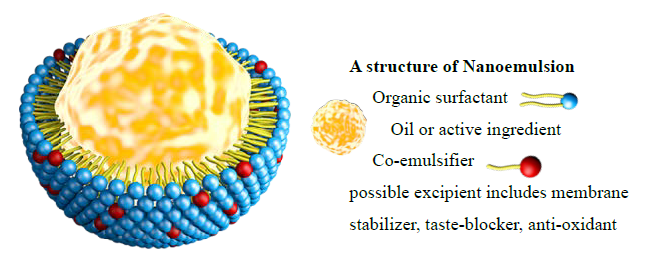

Nanoemulsions, also known as microemulsions, are thermodynamically stable, isotropic, transparent, or translucent homogeneous dispersion systems with particle sizes ranging from 1 to 100 nm. They are spontaneously formed by mixing water, oil, surfactants, and co-surfactants. Nanoemulsions are generally classified into three types: water-in-oil (O/W), oil-in-water (W/O), and bicontinuous (B.C). This system was first discovered and reported by Hoar and Schulman in 1943, and the term "microemulsion" was introduced by Schulman in 1959. Since then, nanoemulsions have seen rapid development in both theory and application, penetrating fields such as daily chemicals, fine chemicals, petrochemicals, materials science, biotechnology, and environmental science, making it a promising area of research.

Structure of Nanoemulsion

Advantages of Nanoemulsions

Nanoemulsions offer numerous benefits over other formulations:

Isotropic Transparent Liquid: They are thermodynamically stable and do not separate under heat or centrifugation.

Simple Process: They can be formed spontaneously without special equipment, with particle sizes typically between 1-100 nm.

Low Viscosity: This reduces pain during injections.

Sustained Release and Targeting: They provide controlled release and targeting effects.

Enhanced Drug Solubility and Absorption: They improve drug solubility, reduce enzymatic degradation in the body, protect the drug, and enhance gastrointestinal absorption, thus increasing bioavailability.

Preparation Methods and Principles of Nanoemulsions

Nanoemulsification can be divided into mechanical and physicochemical methods. Being a non-equilibrium system, nanoemulsion formation requires external energy, which can come from mechanical equipment or the structural potential of chemical components.

- Mechanical Methods

Mechanical preparation of nanoemulsions typically involves two steps:

Crude Emulsion Preparation: Mixing oil, water, surfactants, and stabilizers to form a conventional emulsion with a specific particle size distribution using a stirrer.

Nanoemulsion Formation: Using a dynamic ultra-high-pressure microfluidizer or ultrasonic combined with a high-pressure homogenizer to homogenize the crude emulsion under specific conditions to achieve a nanoemulsion.

High-energy emulsification methods, such as high-pressure homogenizers and ultrasonic generators, are effective in providing the required energy quickly to obtain a uniform fluid with the smallest droplet size. Ultra-high-pressure microfluidizers are widely used in nanoemulsion research. Ultrasonic emulsification is particularly effective for small batch production.

- Low-Energy Emulsification Methods

Low-energy methods leverage the principles of curvature and phase transitions during emulsification. The Emulsion Inversion Point (EIP) method, developed by Marszall and Shick, involves observing phase transitions by continuously changing the components at a constant temperature. The Phase Inversion Temperature (PIT) method, invented by Shinoda and Saito, involves adjusting the temperature under constant component conditions to obtain the desired emulsified system. Studies have shown that spontaneous emulsification can occur without surfactants, producing nanoemulsions.

Related Articles

What is High Pressure Homogenizer?

Liposome Extruder: Function, Advantages, Types and Selection Guide

Using NanoGenizer High Pressure Homogenizer for Nanomaterials and Cell Disruption