What is Rogers PCB?

Rogers PCB is a type of printed circuit board (PCB) material made from a combination of epoxy and ceramic. It is well known for its high dielectric constant, low loss tangent, and high thermal conductivity, making it an ideal material for high-frequency applications. It is used in a wide range of electronics, such as:

5G Station

Cellular Base Station Antennas and Power Amplifiers

Automotive Radar and Sensors

Microwave point to point (P2P) links

LNB’s for Direct Broadcast Satellites

Microwave equipment of all kinds.

RF Identification (RFID) Tags

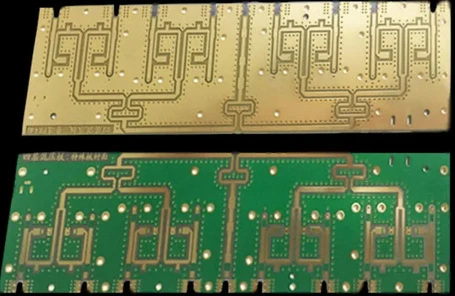

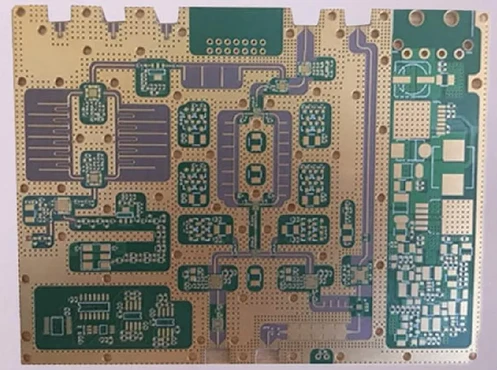

Rogers PCB is produced using the raw materials of the Rogers Company. Rogers company manufactures the laminate materials that are often used for manufacturing circuit boards. The Rogers PCB is a type of high-frequency PCB board, quite different from the traditional PCB board materials, epoxy resin. It uses the ceramic base as the material of high frequency. The major advantage of Rogers PCB is the temperature stability and superior dielectric constant.

Rogers PCB has a major application in high-speed electronic designs, radio frequency applications, and commercial microwaves. The low water absorption capacity of this Rogers PCB is ideal for the application of high humidity. Other Rogers PCB applications include RF identification tags, power amplifiers, automotive radar, sensors, etc.

Rogers PCB fabrication needs in-depth research on high-frequency PCB. HITECHPCB is a Rogers PCB manufacturer and has a deep understanding of the performance of Rogers PCB material. For example, Rogers PCB laminates and Rogers PCB dielectric constant in Rogers PCB material properties Rogers PCB is a high-frequency PCB material model produced by Rogers company, different from the conventional FR-4 PCB material. There is no epoxy resin in the Rogers PCB material, and Rogers ceramic PCB is used as the High-frequency PCB material. Absorption of Rogers PCB, it can be used as an ideal choice for application ns in high humidity environments, providing customers in the high-frequency PCB industry with the highest quality Rogers PCB material and high-quality PCB quality

How to choose PCB materials for High -Frequency applications?

The PCB laminate material you choose for PCB building is essential for the overall function and lifespan of the final product. When the operating frequency enters the microwave oven and even the RF frequency (RF) region, your PCB laminate material selection will have a significant impact on the overall loss of the finished PCB after PCB assembly and final assembly. When determining the best material suitable for High-Frequency PCB manufacturing, you must carefully consider electrical, heat and mechanical properties.

In high frequency design, you may find that FR4 sometimes does this job just at certain higher frequencies. It’s obviously you choose the wrong PCB material. In high frequencies, FR4's main attention is its relatively high dielectric constant (DK), which is generally considered to be about 4.2. In terms of hybrid structure, FR4 can still be used as a suitable laminate material for High-Frequency PCB, when it comes to a hybrid construction, in which the fabrication is combined with high frequency laminate. At Hitech Circuits, we carry a series of specially designed materials to maintain signal integrity in the radio frequency and microwave regions.

Materials for high-frequency circuit boards

High -frequency board has special requirements for the materials used:

1. Adapted dielectric dielectric constant

2. The attenuation of valid signal transmission is low

3. Uniform structure, low insulation thickness and dielectric constants low tolerance

For in many applications, FR-4 materials with appropriate accumulation are used. In addition, we handle high -frequency materials with improved dielectric characteristics. These have very low loss factor (DF), a low-dielectric constant, which is mainly related to temperature and frequency.

Other favorable features are high glass transition temperature (TG), excellent thermal durability and very low hydrophilic rate.

We use PTFE materials for high-frequency printing circuit boards for impedance control. The sandwich accumulation of material combination (hybrid structure) can also be achieved.

Like Rogers, Isola, Taconic, Arlon, they are all have the common used high frequency PCB material.

Benefits of the Rogers Printed Circuit Board

Printed circuit boards developed from the Rogers material have multiple benefits, and these include the following.

Rogers PCB possesses low moisture absorption and thermal expansion, besides solid dimensional stability under diverse conditions.

Rogers PCB material possesses high compatibility and simplicity in terms of fabrication because of its thinness (normally 0.1mm)

It also has exceptional thermal management, making it ideal for circuits and electronic elements or devices producing excess heat.

Another crucial feature that proves so useful entails reduced outgassing, especially in space applications.

The Rogers printed circuit board matches the trace dimensions and locations, consequently improving the impedance control.

Rogers’s printed circuit board offers a stable high-frequency performance

Characteristics of the high frequency Circuit board

1. The dielectric constant (Dk) must be small and stable, usually as small as possible. The signal transmission rate is inversely proportional to the square root of the material’s dielectric constant, and the high dielectric constant is liable to cause signal transmission delay.

2. The dielectric loss (Df) must be small. This mainly affects the quality of signal transmission. The smaller the dielectric loss, the smaller the signal loss.

3. The coefficient of thermal expansion of the copper foil is as uniform as possible. Because the inconsistency will cause the copper foil to separate during the cold and hot changes.

4. Low water absorption. High water absorption will affect the dielectric constant and dielectric loss during moisture.

5. Other heat resistance, chemical resistance, impact strength, peel strength, etc. must also be good

Then, what’s the advantage of high frequancy PCB?

The high-frequency circuit board with a small dielectric constant (DK) will be small, and the advanced sensing heating technology can achieve the demand for target heating, and the efficiency is very high. Of course, while paying attention to efficiency, it also has environmental protection characteristics, which is very suitable for the development direction of today's society.

The transmission speed is inversely proportional to the square root of the dielectric constant, which means that the smaller the dielectric constant, the faster the transmission speed. This is the advantage of high-frequency circuit boards. It uses special materials, which not only ensures the small characteristics of the dielectric constant, but also maintains stable operation. It is very important for signal conduction.

High-frequency circuit boards that are widely used in various industries for the demand for precision metal material heating treatment. In the process of their fields, not only can it be heated in different depth components, but also focuses on local characteristics. Concentration or decentralized heating method can be easily completed.

The constant and medium of the dielectric will have certain requirements for the environment, especially in the south. Wet weather will seriously affect the use of circuit board. The high-frequency circuit board made from very low water absorption materials can challenge this environment. At the same time, it also has the advantages of resisting the corrosion of chemical items. If you are still skeptical about incorporating high frequency PCBs in your electronics, you can always approach an industry expert in Hitech Circuits. The company has provided standard, as well as customized high frequency circuit boards to various industries.

https://www.hitechpcba.com/rogers-pcb

https://twitter.com/Roger_PCB_PCBA

https://www.facebook.com/luo.roger.1675/

https://www.instagram.com/roger_hitechpcb_pcba/

https://www.hitechpcba.com

https://www.hitechcircuits.com

https://www.htmpcb.com