In the realm of engineering and product development, Computer-Aided Engineering (CAE) software stands as a pillar of innovation, offering the power to simulate, analyze, and optimize designs before they take physical form. However, the path to harnessing the full potential of CAE is not without its challenges. From technological hurdles to organizational dynamics, organizations often encounter obstacles during CAE implementation. This article dives into these common challenges and presents best practices for overcoming them, ensuring a seamless integration that unlocks the true benefits of CAE.

- The Challenge of Tool Selection: Navigating the Maze

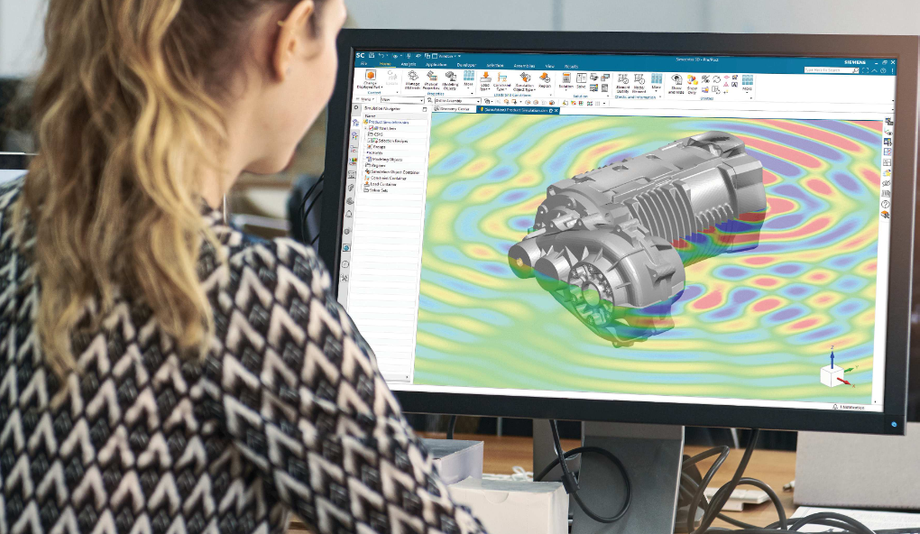

The landscape of Simcenter 3d CAE software is vast, with a multitude of tools tailored to different industries, applications, and complexities. Selecting the right tool is a crucial decision that can shape the success of CAE implementation. The best practice here is to start by clearly defining your organization's needs and goals. Identify the specific simulations you'll be performing, the level of complexity required, and the integration capabilities with other software in your tech stack. Collaborate closely with both your engineering team and software vendors to ensure alignment between expectations and capabilities.

- Ensuring Adequate Training and Skill Development

CAE software is a powerful tool, but its effective use demands a certain level of expertise. Lack of training and skill development can lead to underutilization or even misuse of the software. The solution lies in investing in comprehensive training programs. These can be vendor-provided or in-house, tailored to the specific tools you've chosen. Encourage your engineering team to undergo continuous skill enhancement, ensuring they stay updated with the latest features and techniques.

- Integration with Existing Workflows: Bridging the Gap

Implementing CAE can sometimes disrupt existing workflows, leading to resistance from team members accustomed to traditional methods. The key here is a gradual transition. Begin by identifying points in your workflow where CAE can add the most value without causing massive disruptions. Collaborate closely with your engineering team to gain their insights and involve them in the decision-making process. Over time, as the benefits of CAE become evident, the transition will become smoother.

- Data Management and Collaboration

CAE simulations generate substantial amounts of data, and effective management of this data is a challenge often encountered. Ensuring that simulations are repeatable, well-documented, and easily accessible is crucial. This can be achieved through dedicated data management tools or integration with existing Product Lifecycle Management (PLM) systems. Moreover, fostering collaboration among team members who might be working on different aspects of a project is essential. Regular communication, centralized documentation, and collaborative platforms can help bridge the gaps.

- Hardware and Scalability

CAE simulations can be computationally intensive, demanding substantial hardware resources. Scaling up to meet the requirements of complex simulations can be daunting. The solution lies in a well-defined hardware strategy. Invest in high-performance computing (HPC) resources or consider cloud-based solutions for flexible scalability. Collaborate with IT teams to ensure the hardware and infrastructure can handle the demands of CAE without hindering productivity.

- Resistance to Change: Cultural and Organizational Shifts

Change can be met with resistance, especially in organizations where traditional methods have prevailed for years. Overcoming this challenge requires a cultural shift. Leadership plays a vital role here by communicating the benefits of CAE to the entire organization. Highlight success stories, demonstrate how CAE enhances efficiency and accuracy, and emphasize that it's a tool that complements the expertise of engineers rather than replacing them.

In conclusion, CAE implementation presents its share of challenges, but with the right strategies in place, these obstacles can be transformed into stepping stones toward greater efficiency and innovation. By selecting the right tools, providing adequate training, fostering collaboration, managing data effectively, ensuring hardware scalability, and driving a cultural shift, organizations can successfully integrate CAE into their workflows, ultimately reaping the rewards of enhanced product development and decision-making.

For Free CAE Software Trials, Download Siemens CAE Software!